High-temperature-resistant cable sheath material and preparation method thereof

A technology of high temperature resistance and sheath material, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of heat resistance and aging resistance of sheath materials, limit the use environment and use temperature, etc., and achieve good flame retardant effect , broaden the scope of use, the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

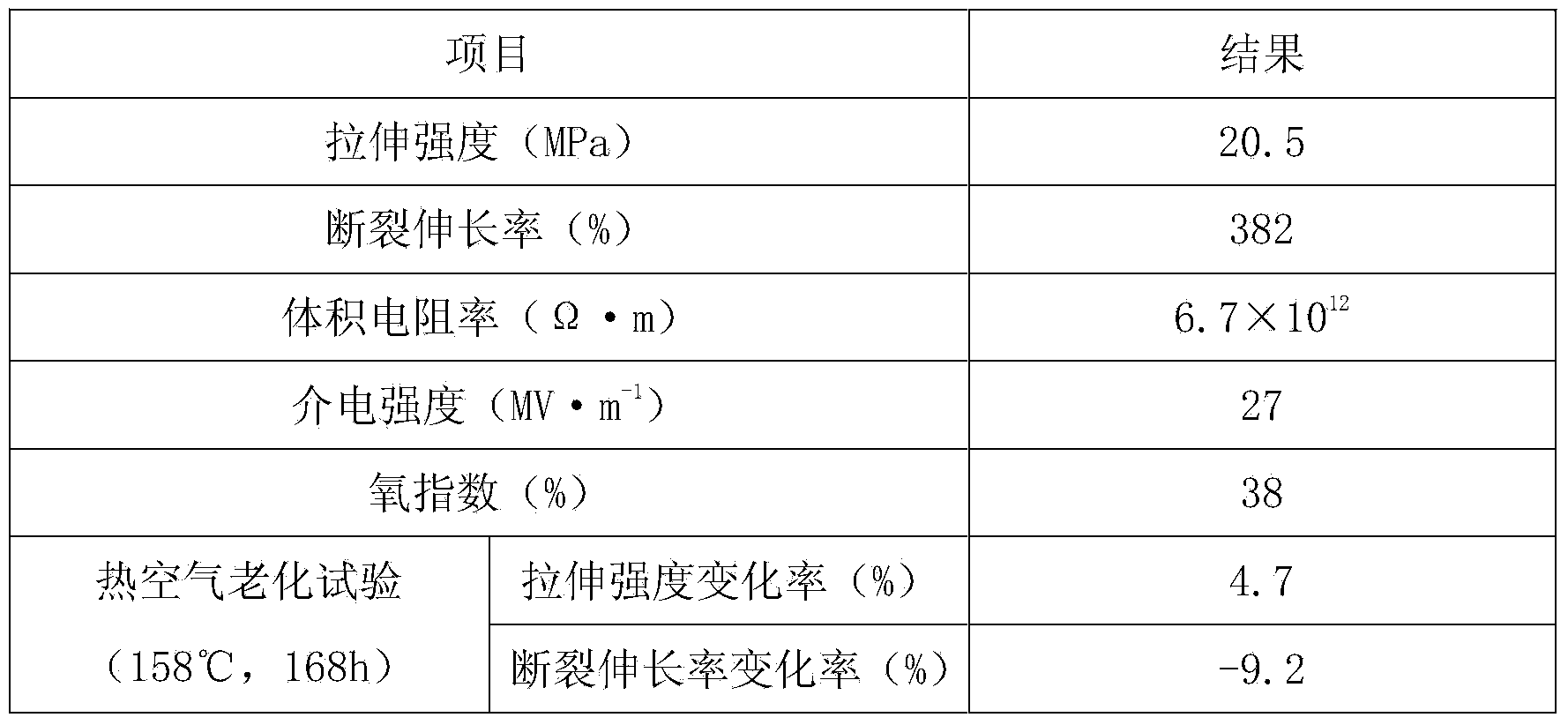

Examples

Embodiment Construction

[0010] A high-temperature-resistant sheath material for cables, made of the following raw materials (kg): high-density polyethylene 75, EPDM rubber 25, maleic anhydride grafted polyethylene 12, bisphenol A novolac epoxy Resin 8, toluene diphenyl phosphate 10, dioctyl maleate 6, bis-tert-butylperoxycumene 0.7, p-benzoquinone dioxime 2.5, triallyl isocyanurate 1.5, paraffin oil 4. Active zinc oxide 2, magnesium hydroxide 12, aluminum hydroxide 8, talc powder 5, fly ash 10, nano bauxite 8, dibutyltin dilaurate 2, antioxidant MB2, antioxidant TPPD1, composite filler 5 ;

[0011] The preparation method of the composite filler is as follows: a. Take bentonite, barite, and monazite in a weight ratio of 5:3:3, then add 2.5% coal powder and 1.5% activated carbon by weight of bentonite, and mix them uniformly at 550 ° C. Calcined for 4 hours, cooled to room temperature, crushed to a particle size below 15 μm, then added water to beat to make a slurry with a concentration of 45%, added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com