High cold-resistance ethylene propylene diene copolymer insulated cable material and preparation method thereof

A technology of EPDM rubber and insulated cables, applied in organic insulators, plastic/resin/wax insulators, etc., can solve the problems of easy embrittlement and poor cold resistance of cables, and achieve low cost, excellent flame retardancy, and improved resistance. Effects of flammability and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

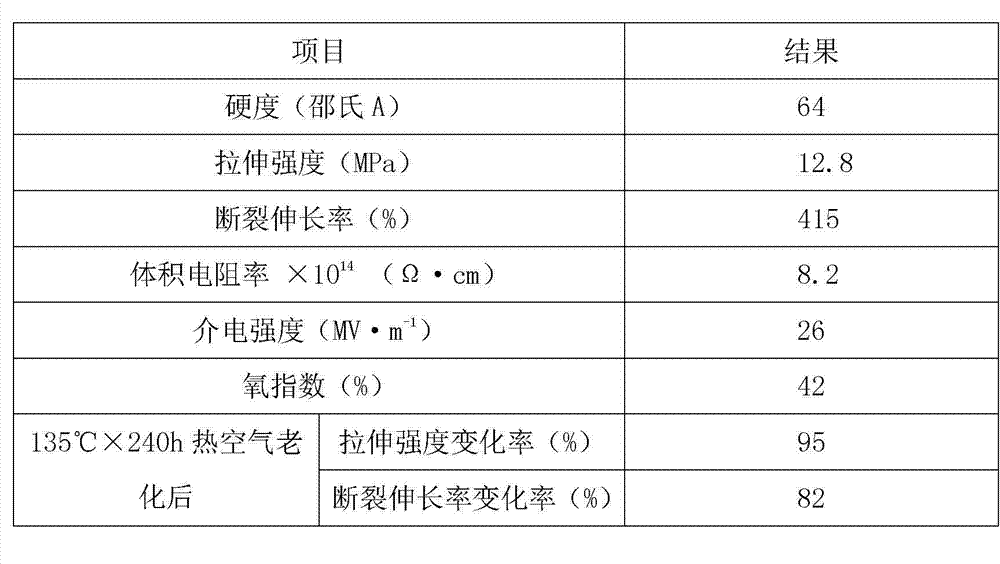

Image

Examples

Embodiment

[0013] A high cold-resistant EPDM insulating cable material, made of the following raw materials in parts by weight: 80 parts of German LANXESS 9650 EPDM rubber, 25 parts of active chlorine-type acrylate rubber AR-400, Neoprene CR121 12 parts, 15 parts of di-n-butyl nylon acid, 8 parts of trioctyl trimellitate, 8 parts of triethyl phosphate, 1.5 parts of sulfur, 3 parts of benzoyl peroxide, triallyl isocyanuric acid 1.5 parts of ester, 1.5 parts of zinc oxide, 3 parts of stearic acid, 2 parts of zinc stearate, 1 part of barium stearate, 1.5 parts of vinyl tris(β-methoxyethoxy) silane, bis(dioctyl 0.8 parts of oxypyrophosphate) ethylene titanate, 16 parts of ammonium polyphosphate, 42 parts of nano-bentonite, 16 parts of nano-mica powder, 35 parts of fumed silica, 12 parts of carbon black N550, and 1.5 parts of antioxidant 2246 2 parts, anti-aging agent DFC-34 2 parts, anti-aging agent ODA 1 part, accelerator NOBS 2 parts, accelerator PZ 1.5 parts, modified tree ash 3 parts. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com