Phase change fracturing fluid system for phase change fracturing

A phase change fracturing and liquid technology, which is applied in the fields of fluid production, drilling composition, wellbore/well components, etc., can solve the problems of difficult injection, difficult injection, complicated process implementation, etc. The effect of crack construction is easy to operate and reduces construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First take 50g of toluene, then add 5g of melamine, 5g of triallyl isocyanurate, 10g of vinyl acetate, 1g of sodium dodecylbenzenesulfonate, 0.5g of hydrogen peroxide, and 1g of polyethylene glycol in sequence. Put everything in a flask and stir evenly at room temperature to complete the preparation of phase change fracturing fluid FfP1.

[0020] Place the well-stirred FfP1 flask in a constant temperature oil bath, raise the temperature to 80-90°C and react for 0.5-5 hours, stop heating, take out the flask and observe beads and massive solid phases appearing in the FfP1 sample. It shows that the phase change fracturing fluid FfP1 can be used in phase inversion fracturing, and can realize the transition from liquid phase to solid phase.

Embodiment 2

[0022] First take 50g of o-xylene, then add 12g of melamine, 10g of vinyl acetate, 2g of acrylonitrile, 0.5g of sodium dodecylbenzenesulfonate, Tween 20 (0.5g), 2g of sodium phosphate, and 0.5g of ammonium persulfate. Stir evenly at room temperature to complete the preparation of phase change fracturing fluid FfP2.

[0023] Place the well-stirred FfP2 flask in a constant temperature oil bath, raise the temperature to 90-100°C and react for 0.5-5 hours, stop heating, take out the flask and observe the appearance of beads and massive solid phases in the FfP2 sample. It shows that the phase change fracturing fluid FfP2 can be used in phase inversion fracturing, and can realize the transition from liquid phase to solid phase.

Embodiment 3

[0025] First take 50g of ethylbenzene, then add 10g of melamine, 4g of triallyl isocyanurate, 10g of acrylonitrile, 0.5g of sodium dodecylbenzenesulfonate, and 0.5g of cetyltrimethylammonium bromide , calcium chloride 2g, hydrogen peroxide 1g, polyvinylpyrrolidone 1g. Stir evenly at room temperature to complete the preparation of phase change fracturing fluid FfP3.

[0026] Place the well-stirred FfP3 flask in a constant temperature oil bath, raise the temperature to 70-80°C and react for 0.5-5 hours, stop heating, take out the flask and observe the appearance of beads and massive solid phases in the FfP3 sample. It shows that the phase change fracturing fluid FfP3 can be used in phase inversion fracturing, and can realize the transition from liquid phase to solid phase.

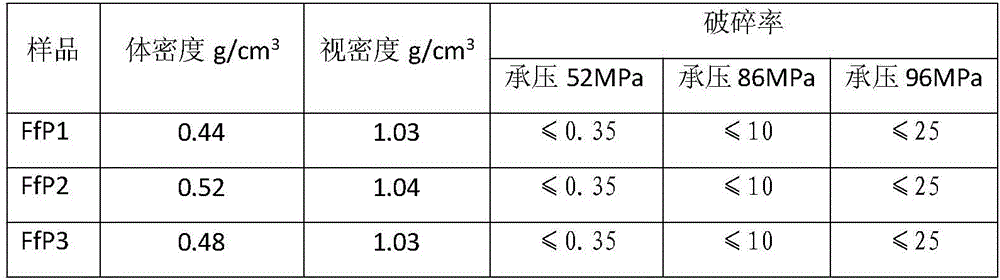

[0027] Table 1 Solid phase properties of phase change fracturing fluid after phase change

[0028]

[0029] The data in Table 1 shows that the density of the solid phase after the phase transition is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com