Water tree-resistant polyethylene insulated cable material and preparation method thereof

A polyethylene insulation and cable material technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve problems affecting the reliability of polyethylene cables, hidden dangers of power grid safety operation, etc., to improve resistance to water tree aging and physical machinery. performance, improved safety, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

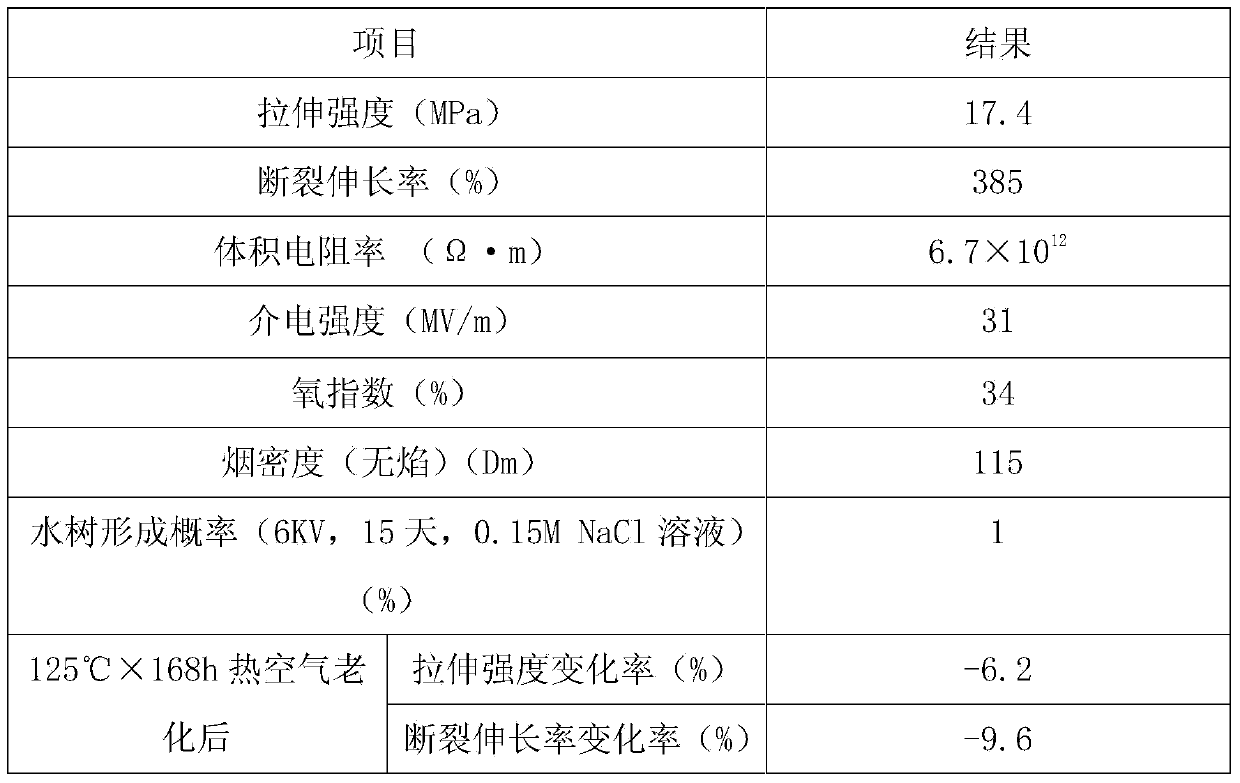

Examples

Embodiment Construction

[0010] A water-tree-resistant polyethylene insulated cable material, which is made of the following raw materials (kg): low-density polyethylene 80, maleic anhydride grafted EVA12 maleic anhydride grafted POE8, sorbitol 1, polyethylene glycol Alcohol 2, dicumyl peroxide 2, antioxidant DLTP0.5, triallyl cyanurate 3, tribasic lead sulfate 1.5, polydimethylsiloxane 3, magnesium oxide 2, stearin Acid 3, organic bentonite 10, calcium sulfate whisker 10, semi-reinforcing carbon black N77018, composite filler 6, diisobutyl phthalate 8, N-cyclohexylthiophthalimide 1.5, Antiaging agent DDM2, accelerator TMTD1, accelerator DPTT2;

[0011] The preparation method of the composite filler is as follows: a. Take the following raw materials by weight (kg): fluorite 10, dolomite 10, acrylic acid 12, jade powder 10, ammonium persulfate 0.15, urotropine 0.8, volcanic ash 4, hydrogen Aluminum oxide 6, barium sulfate whisker 4, calcium stearate 2, mullite 8, polytetrafluoroethylene micropowder 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com