Flame-retardant resin composition

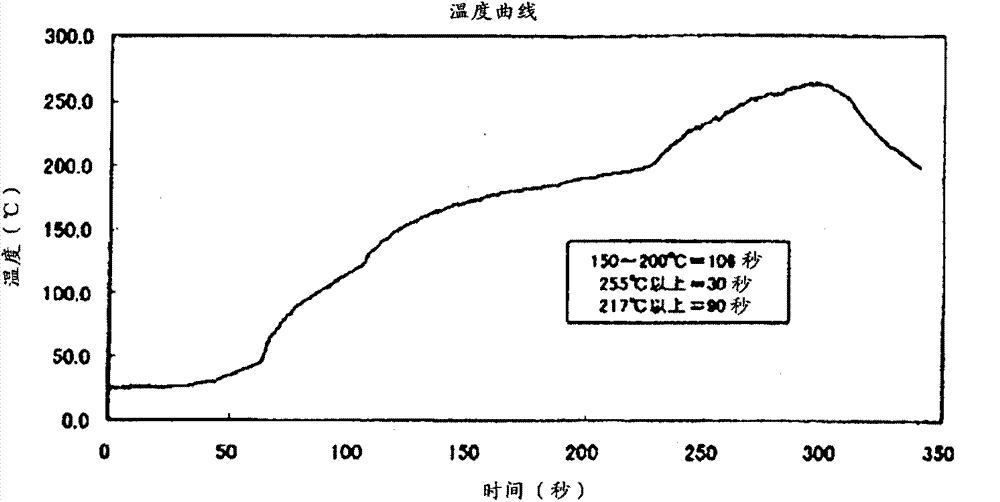

A resin composition, flame retardant technology, applied in the direction of fire retardant coatings, etc., to achieve the effect of excellent reflow heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

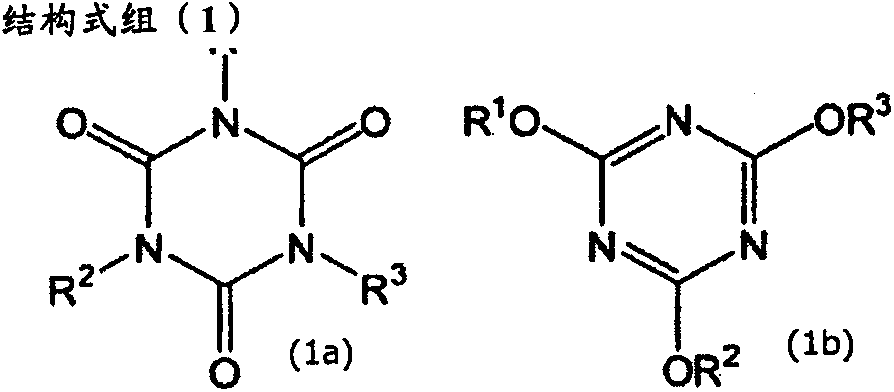

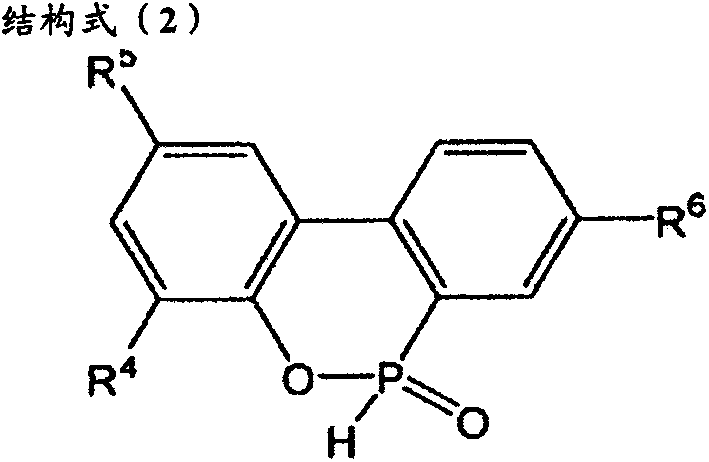

[0294] (Manufacture example 1) [polymerization process]

[0295]A phosphorus-containing compound (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, product name: HCA, manufactured by Sanko Co., Ltd.) and a nitrogen-containing compound (triallylisocyanurate Ester, product name: TAICROS, manufactured by Ebonick Degusa) is put into a vertical polymerizer with a reflux pipe, a nitrogen introduction pipe and a stirrer at a molar ratio of 1:2, and then the total amount of the phosphorus-containing compound and the nitrogen-containing compound is 0.1 part by weight of a radical initiator (2,3-dimethyl-2,3-diphenylbutane, product name: Novoma BC, manufactured by NOF Corporation) per 100 parts by weight. Under a nitrogen stream, the temperature was slowly raised to 50° C. to 200° C., and stirred for about 12 hours. The obtained flame retardant (B1) had a phosphorus content of 8.5%, a Tg of 127° C., and was a colorless glassy solid at room temperature. Each sample was insoluble in to...

manufacture example 2

[0296] (Manufacturing example 2) [Crosslinking process]

[0297] 100 parts by weight of flame retardant (B1) obtained in manufacture example 1 and free radical initiator (1,3-bis(tert-butylperoxyisopropyl)benzene, product name: perbuchiru P, NOF Co., Ltd.) 0.2 parts by weight were dry-blended to obtain a mixture. The above-mentioned mixture was supplied from the hopper hole of a vented 15 mmφ co-directional twin-screw extruder (manufactured by Technobell Corporation, KZW15TWIN-45MG), and melted and kneaded at a drum setting temperature of 190 to 220°C. The obtained flame retardant (B2) was a colorless glassy solid (Tg: 138° C.) at normal temperature, and each sample was insoluble in toluene and THF. In addition, the phosphorus content was 8.9%, and the cross-linking component ratio was 68%. In addition, the flame retardant (B2) was insoluble in chloroform, and the weight average molecular weight could not be measured.

manufacture example 3

[0299] In the crosslinking step of Production Example 2, 5 parts by weight of inorganic compound (E1) and free radical initiator (1 , 3-bis(tert-butylperoxycumyl)benzene, product name: Perbutil P, manufactured by NOF Corporation) 0.2 parts by weight, melt-kneading in the same manner as in Production Example 2, to obtain a flame retardant ( B3). The obtained flame retardant (B3) was a white glassy solid (Tg: 139° C.) at normal temperature, and was insoluble in toluene and THF. Furthermore, the phosphorus content was 8.7%, and the ratio of the cross-linking component was 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com