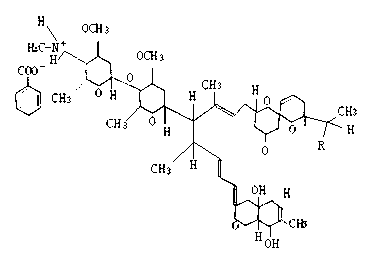

Emamectin benzoate polylactic acid microsphere suspension and preparation method thereof

A technology of polylactic acid microspheres and emamectin benzoate, applied in botany equipment and methods, biocides, biocides, etc., can solve problems such as not easy to degrade, and achieve the effect of simple preparation method, remarkable effect and unique formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: A kind of emamectin benzoate polylactic acid microsphere suspension

[0033] Raw material formula: emamectin benzoate polylactic acid microspheres 3.03 grams, sodium lauryl sulfate + sodium dodecylbenzene sulfonate 2.52 + 2.55 grams, magnesium aluminum silicate 2.01 grams, ethylene glycol 3.52 grams, sodium benzoate 0.13 grams, water to make up to 100 grams. .

[0034] Preparation method: Take 3.03 grams of emamectin benzoate polylactic acid microspheres, sodium lauryl sulfate + sodium dodecylbenzene sulfonate 2.52 + 2.55 grams, magnesium aluminum silicate 2.01 grams, ethylene glycol 3.52 grams, sodium benzoate 0.13g, make up to 100g with water. Oscillate and dissolve with an oscillating agitator until the solution is uniformly mixed to obtain 3.0% emamectin emamectin salt polylactic acid microsphere suspension.

[0035]Dilute 3% emamectin benzoate polylactic acid microsphere suspension with water 2000-5000 times, and spray evenly, which can effectively...

Embodiment 2

[0036] Embodiment 2: A kind of emamectin benzoate polylactic acid microsphere suspension

[0037] Raw material formula: emamectin benzoate polylactic acid microspheres 3.01 grams, sodium lauryl sulfate + sodium dodecylbenzene sulfonate 3.03 + 3.03 grams, magnesium aluminum silicate 2.51 grams, ethylene glycol 3.03 grams, sodium benzoate 0.11 grams , water to make up to 100 grams.

Embodiment 3

[0038] Embodiment 3: A kind of emamectin benzoate polylactic acid microsphere suspension

[0039] Raw material formula: emamectin benzoate polylactic acid microspheres 3.00 grams, sodium lauryl sulfate + sodium dodecylbenzene sulfonate 3.51 + 3.47 grams, magnesium aluminum silicate 3.01 grams, ethylene glycol 3.49 grams, sodium benzoate 0.10 grams , water to make up to 100 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com