Method for measuring key volatile component in cigarette bead blasting

A technology for volatile components and determination methods, applied in the field of tobacco, can solve the problem of no reports on the qualitative and quantitative analysis of explosive beads, and achieve the effects of good accuracy, good sensitivity and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

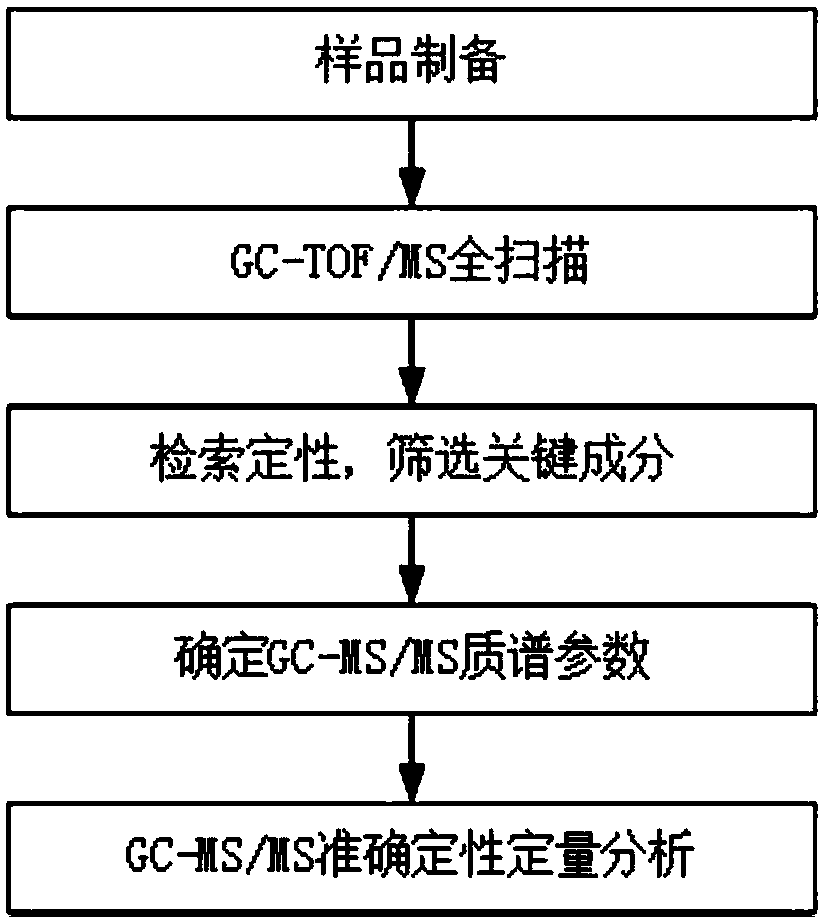

[0028] The determination method steps are:

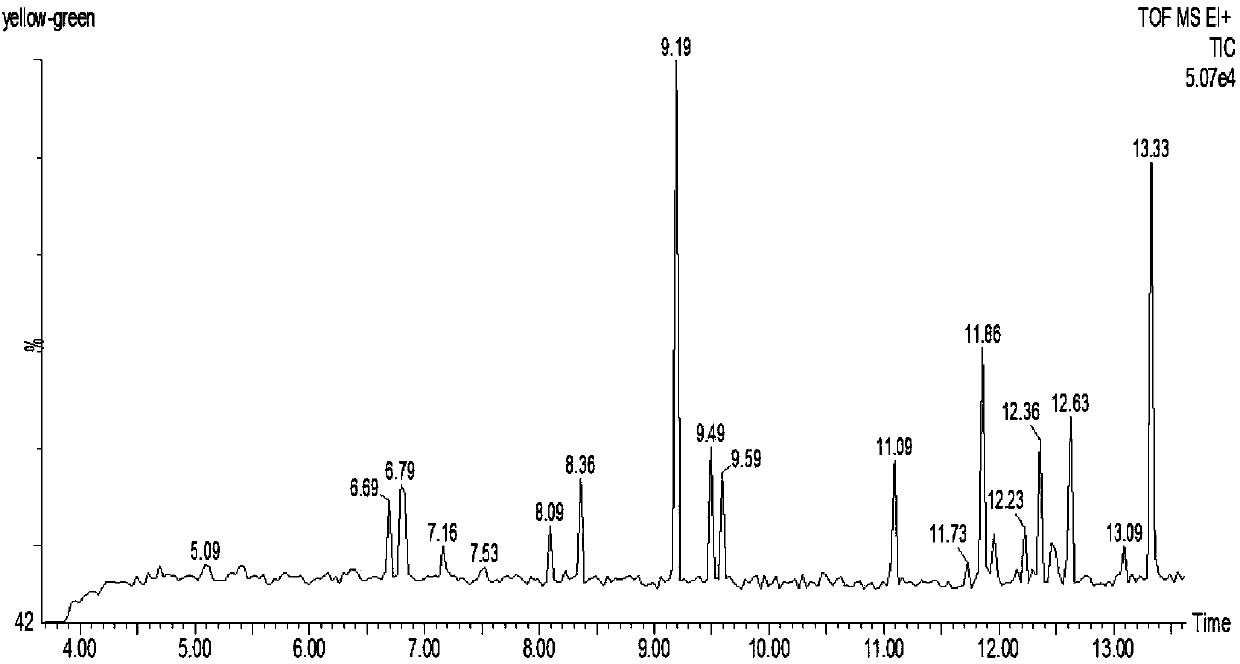

[0029] A. Use isopropanol as a solvent to prepare the sample. The steps are: randomly take a sample of popping bead cigarettes, put the popping beads in a headspace bottle, press the popping beads, add 10mL of isopropanol solution, shake and extract, extract The solution was passed through a 0.22 μm filter membrane. Then use gas chromatography high-resolution time-of-flight mass spectrometry (GC-TOF / MS) to perform full-scan analysis on the liquid in the popping beads to obtain a full-scan map;

[0030] B. Use the database (NIST standard spectrum library) to search to determine the unknown, and screen the key components according to the semi-quantitative results of the area normalization method;

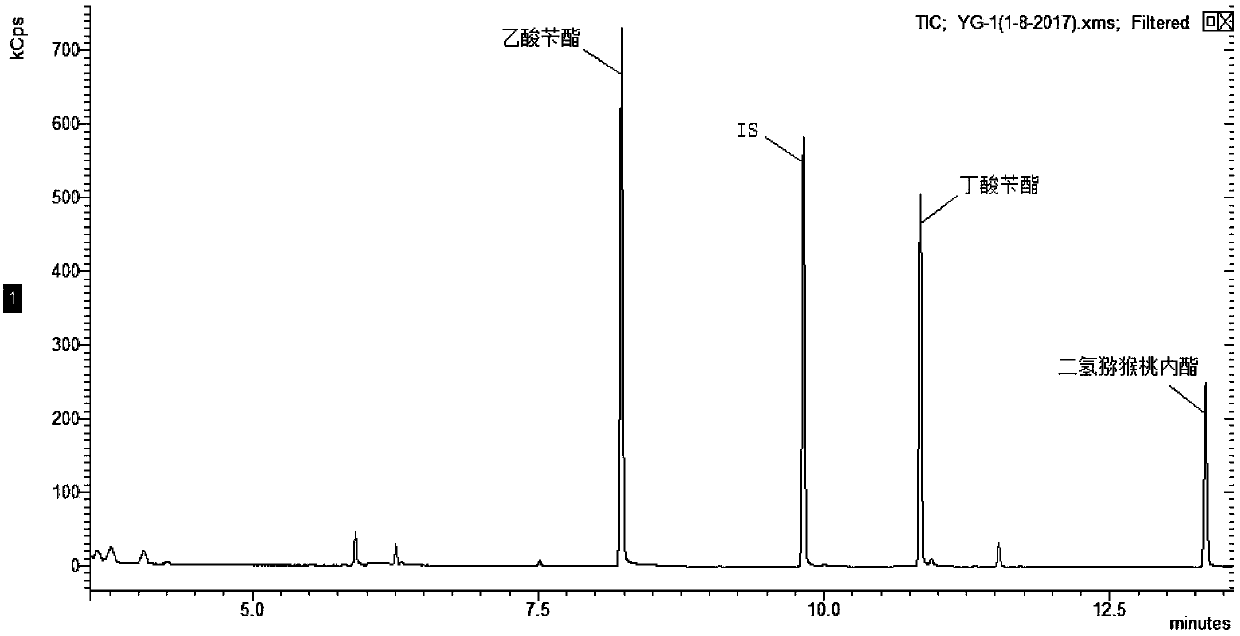

[0031] C, for the key component screened out, with n-propyl benzoate as internal standard, determine the qualitative and quantitative parameters of the mass spectrometry of each component by gas chromatography-secondary mass spectrometry (...

Embodiment 2

[0047] The determination method steps are:

[0048] A. Use isopropanol as a solvent to prepare the sample. The steps are: randomly take a sample of popping bead cigarettes, put the popping beads in a headspace bottle, press the popping beads, add 10mL of isopropanol solution, shake and extract, extract The solution was passed through a 0.22 μm filter membrane. Then use gas chromatography high-resolution time-of-flight mass spectrometry (GC-TOF / MS) to perform full-scan analysis on the liquid in the popping beads to obtain a full-scan map;

[0049] B. Use the database (NIST standard spectrum library) to search to determine the unknown, and screen the key components according to the semi-quantitative results of the area normalization method;

[0050] C, for the key component screened out, with n-propyl benzoate as internal standard, determine the qualitative and quantitative parameters of the mass spectrometry of each component by gas chromatography-secondary mass spectrometry (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com