Preparation method of novel nanoscale fire retardant

A nano-scale, flame retardant technology, applied in the field of coatings, can solve the problems of decreased mechanical properties of materials, easy agglomeration compatibility, affecting the flame retardant properties of materials, etc., to enhance stability, improve flame retardant properties, and improve poor dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

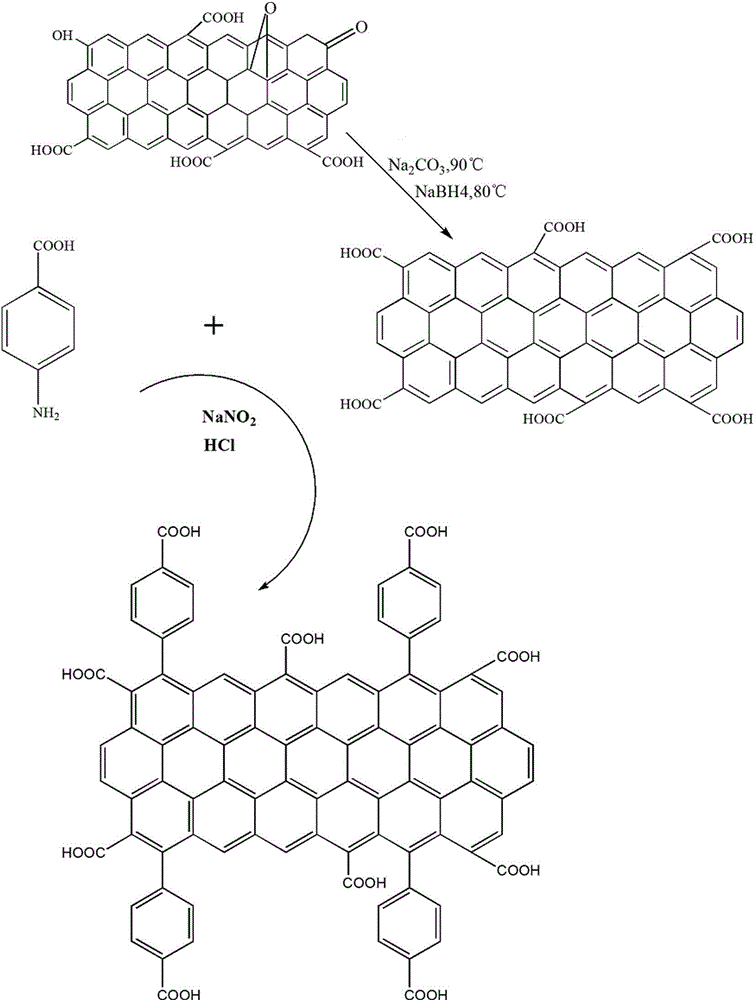

[0016] see figure 1 , figure 2 , this embodiment provides a preparation method of a novel nanoscale flame retardant, including the following steps.

[0017] Step 1. Add 1g of p-aminobenzoic acid and 0.3g of sodium hydroxide to the reaction vessel, and add 80ml of distilled water; then slowly add 0.5g of sodium nitrite and 5ml of 20% HCl at 5°C, and stir for 50min; Add 0.4g of reduced graphene after ultrasonication into the solution, and stir at 5°C for 3h; adjust the pH value of the resulting solution to 2-3, and dialyze 3 times with a dialysis membrane, and then wash the resulting product into the medium with an organic solvent properties, that is, benzoic acid functionalized graphene.

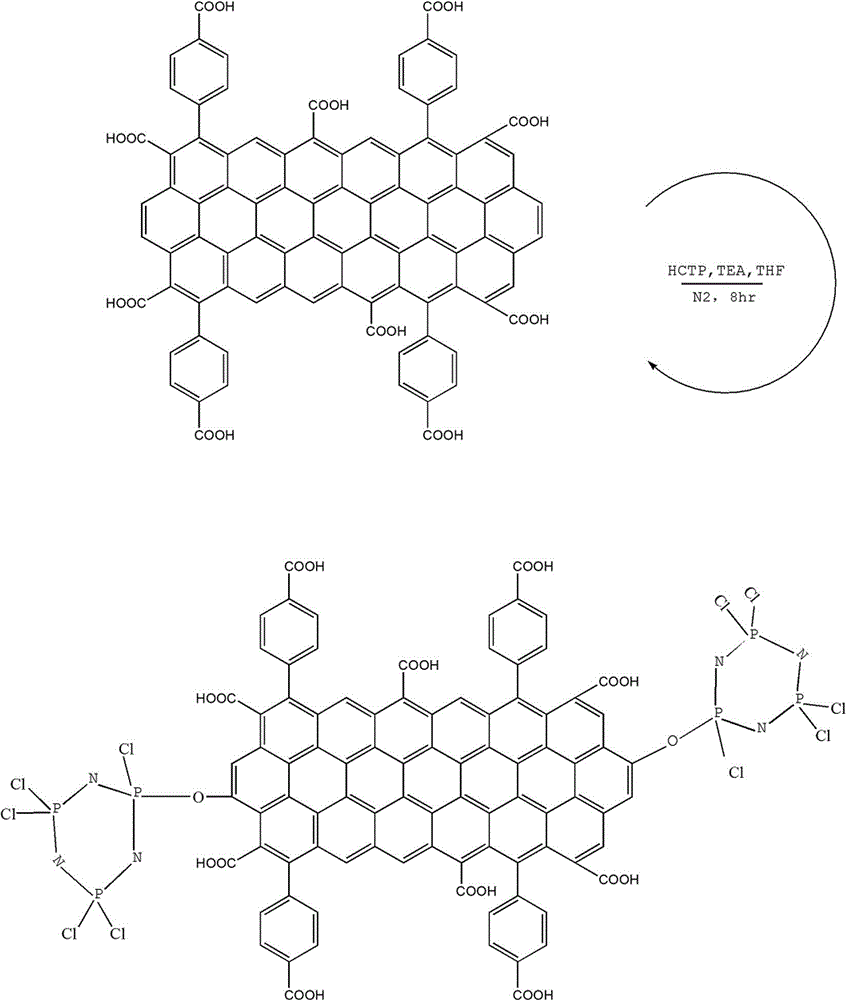

[0018] Step 2. Take 1g of benzoic acid-functionalized graphene, and then ultrasonically disperse it in 100ml of tetrahydrofuran, then pour the solution into a 500ml three-necked flask filled with nitrogen; then add 10.82g of triethylamine under ice bath conditions and stir 1.5h, then add ...

Embodiment 2

[0021] This embodiment provides a method for preparing a novel nanoscale flame retardant, which includes the following steps.

[0022] Step 1. Add 2g of p-aminobenzoic acid and 0.4g of sodium hydroxide to the reaction vessel, and add 100ml of distilled water; then slowly add 0.8g of sodium nitrite and 10ml of 20% HCl at 5°C, and stir for 55min; Add 0.5g of reduced graphene after ultrasonication into the solution, and stir at 5°C for 3.5h; adjust the pH value of the resulting solution to 2-3, and dialyze twice with a dialysis membrane, and then wash the resulting product with an organic solvent to Neutral, that is, benzoic acid functionalized graphene.

[0023] Step 2. Take 2g of benzoic acid-functionalized graphene, and then ultrasonically disperse it in 100ml of tetrahydrofuran, and then pour the solution into a 500ml three-necked flask filled with nitrogen. Then add 11g triethylamine under ice bath condition and stir for 2h, then add 4g hexachlorocyclotriphosphazene and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com