Ferrous metallurgy pellet iron-containing raw material preprocessing and dosing system

A ferrous raw material and iron and steel metallurgy technology, applied in the field of material metallurgy, can solve the one-time investment, energy consumption and daily maintenance and repair costs of reversing equipment and belt conveyor corridors, the increase in equipment investment and infrastructure costs, and the occupation of the batching room. Large area and other problems, to achieve the effect of easy daily operation and maintenance, reduce floor space, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

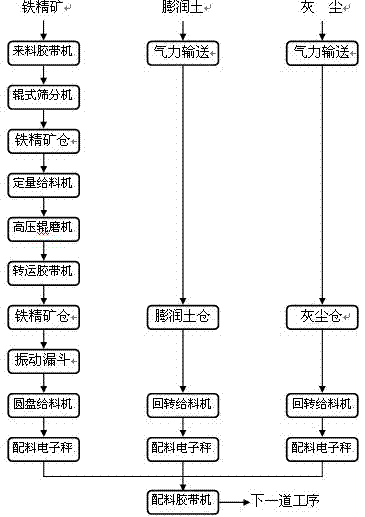

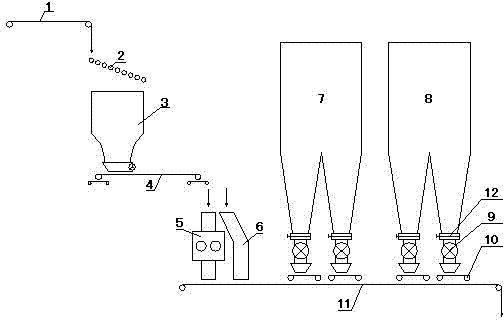

[0031] Such as figure 2As shown, the pretreatment and batching system of pellet iron-containing raw materials for iron and steel metallurgy of the present invention mainly separates the iron concentrate warehouse from the batching chamber, and it can be considered to be arranged separately from the batching room, or the high-pressure roller mill chamber and the batching room can be unified Arrangement, in this embodiment, the high-pressure roller mill chamber and the batching chamber are arranged separately. The iron concentrate with qualified water content does not enter the batching room, but first enters the high-pressure roller mill, and then directly transports it to the batching belt conveyor 11. In order to achieve the above purpose, the pretreatment and batching system of iron-containing pellets for iron and steel metallurgy includes in sequence according to the direction of material flow: incoming material belt conveyor 1; roller screening machine 2, which is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com