Ore-blending and smelting method of ocean cobalt-rich crusts

A cobalt-rich crust and ore blending technology is applied in the smelting field of seabed manganese-containing polymetallic ore, which can solve the problems that it is not suitable for smelting manganese-rich slag alone, achieve optimized separation and recovery and environmental resource protection, and facilitate production management and optimization. The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

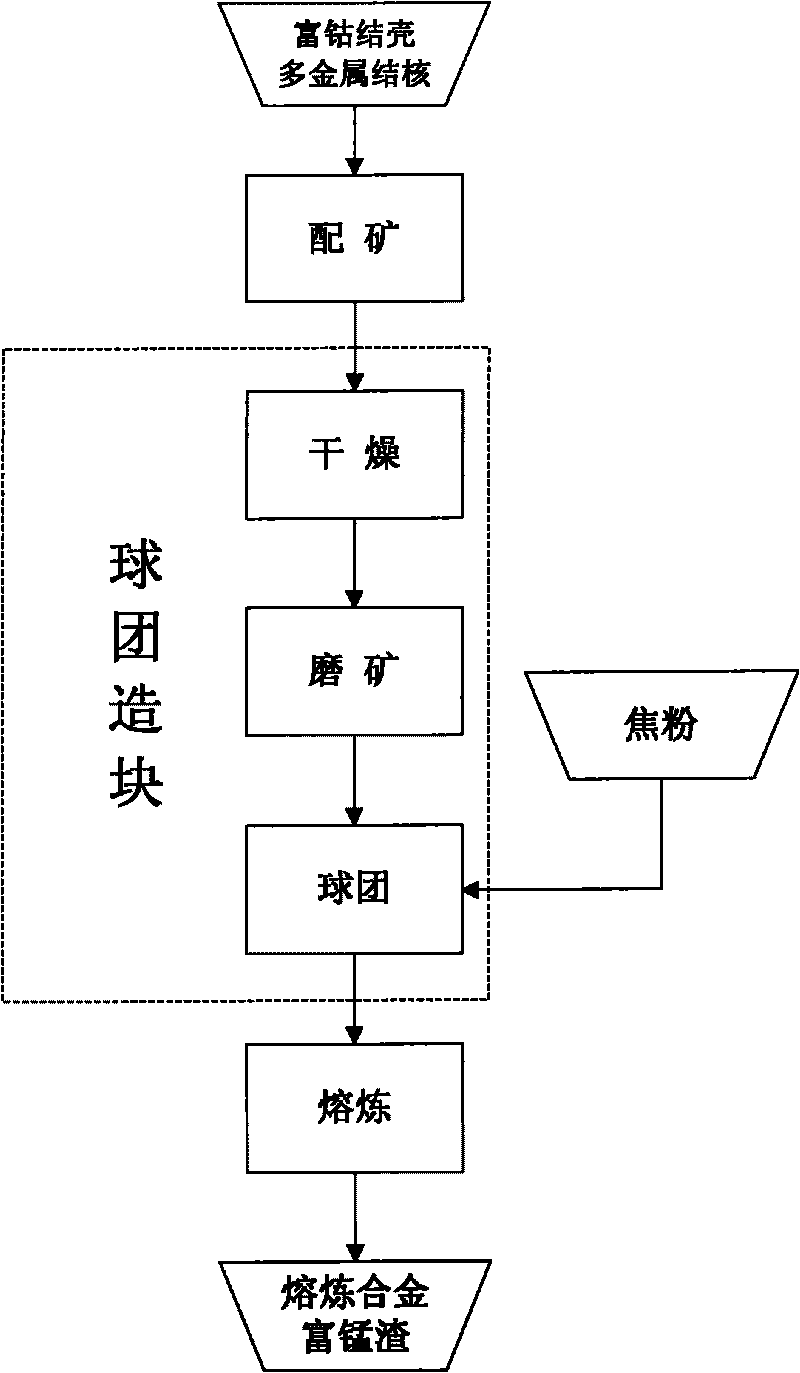

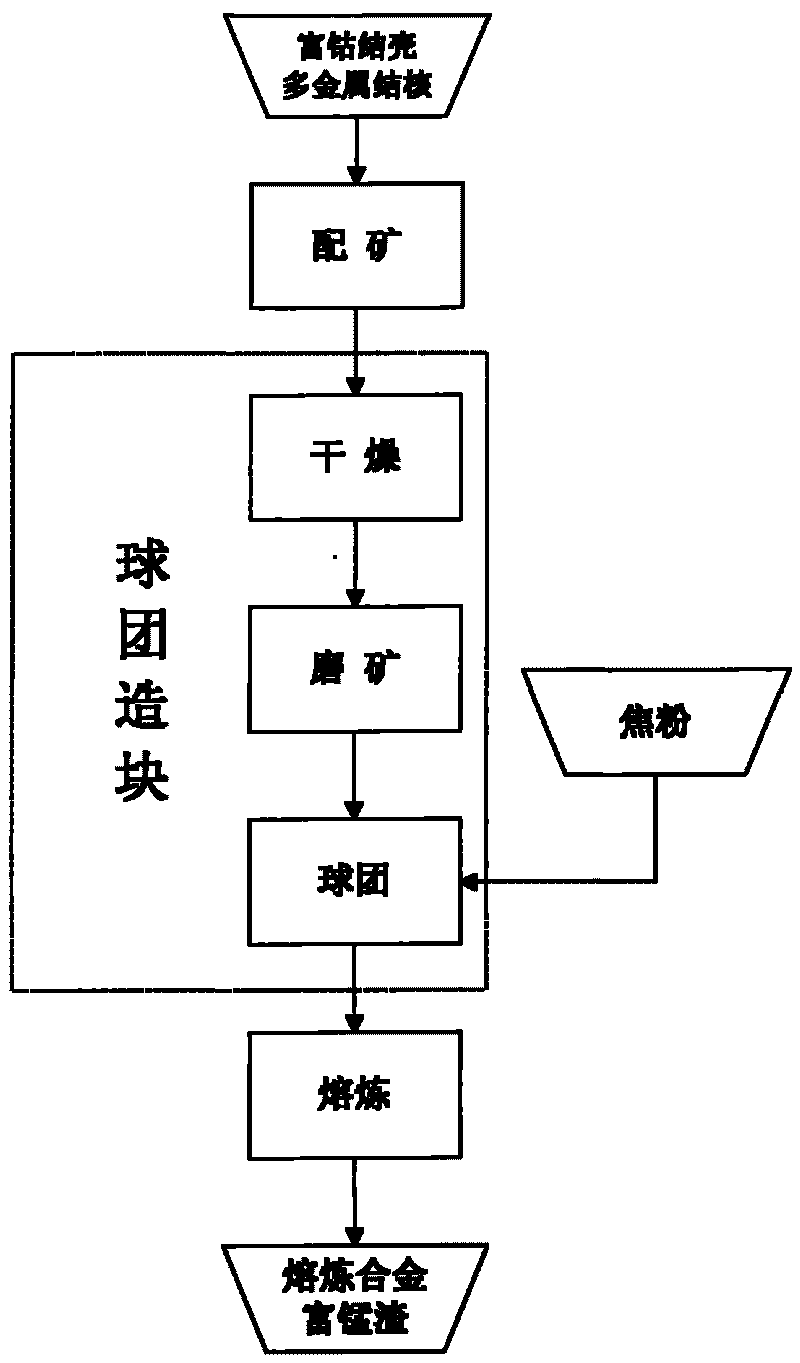

[0025] A kind of ore blending and smelting method of oceanic cobalt-rich crust of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0026] 1. Ore blending: First, select oceanic cobalt-rich crusts and oceanic polymetallic nodules with four different compositions as shown in Table 1 as raw material ores, and then add oceanic cobalt-rich crusts into oceanic cobalt-rich crusts according to the ore blending ratio in Table 2. The metal nodules are blended, and the properties of the furnace pellets of each mixed raw material ore after blending are shown in Table 3.

[0027] Table 1: Chemical composition of oceanic cobalt-rich crusts and oceanic polymetallic nodules

[0028]

[0029] Note: Oceanic cobalt-rich crusts and oceanic polymetallic nodules are provided by the Oceanographic Association. DY95-9, DY105-11, DY105-15, and DY105-13 under the name column in Table 1 above represent exploration sampling voyages, and R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com