Method for producing fuel ethanol and by-product rice DDGS by rice processing

A technology of fuel ethanol and by-products, applied in the direction of biofuels, fermentation, etc., can solve the problems of waste of food resources, increase of process costs, etc., and achieve the effect of improving utilization rate, improving economic benefits and profits, and increasing food safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

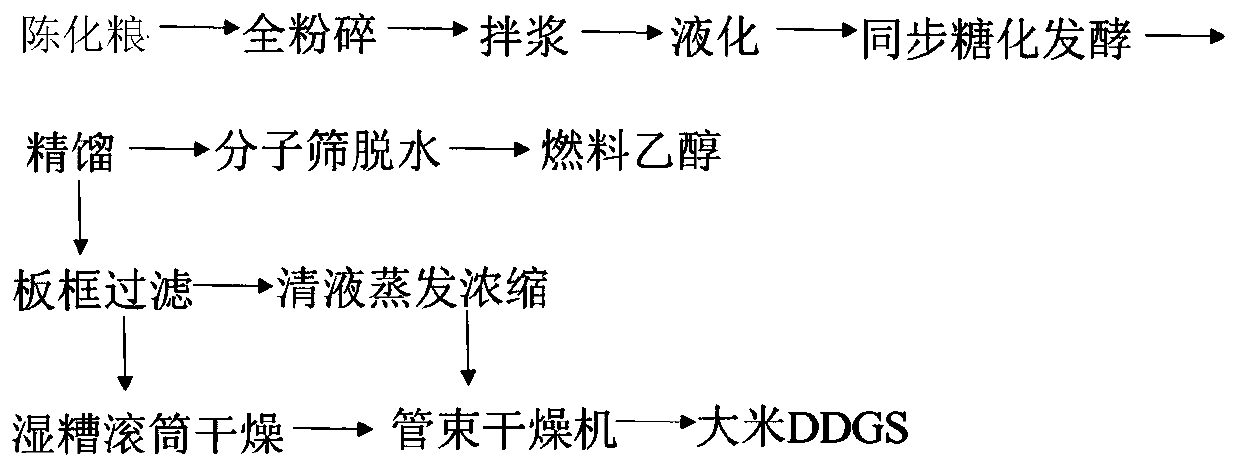

Method used

Image

Examples

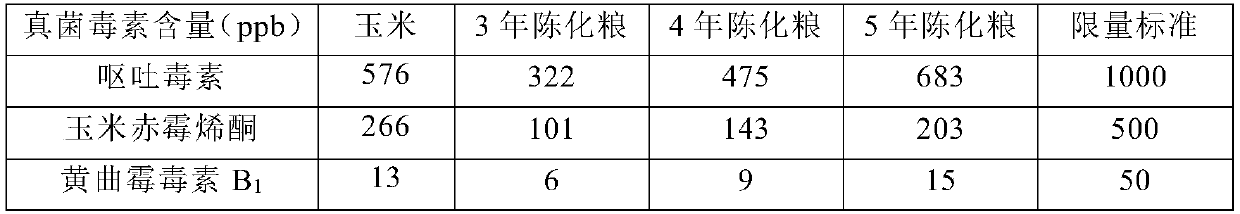

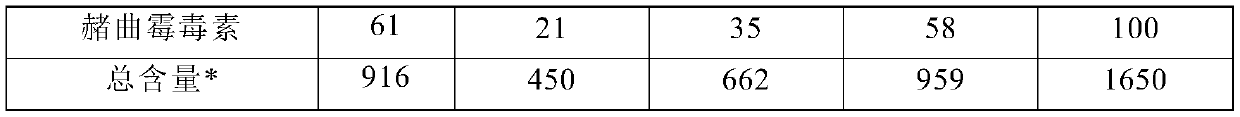

Embodiment 1

[0058] (1) Pretreatment of rice crushing: The aged grains with a storage period of 3 years are passed through a specific gravity destoner (model: TQSF200), an electromagnetic separator (model: RCDB), and a drum grading screen (model: GS1530) in order to remove Impurities such as sand, stone, ironware, and braids. The rice under the drum grading sieve passes through the sand-water separator as part of the rice flour, the rice on the sieve is further pulverized by a hammer mill (model: PC-0604), and the rice under the sieve and the rice on the sieve are crushed The particle size of the powder is to pass through a 25-mesh sieve. After mixing, the material and dust and other impurities are separated by a CZT cyclone separator to obtain rice flour that passes through a 25-mesh sieve.

[0059] (2) Preparation of liquefied mash: Mix rice flour and water evenly to form a slurry, wherein the ratio of rice flour to water is 1:2, adjust the pH to 5.3 with sulfuric acid, and control the d...

Embodiment 2

[0065] (1) Pretreatment of rice crushing: the aged grains with a storage period of 4 years are passed through a specific gravity stone remover (model: TQSF200), an electromagnetic iron remover (model: RCDB), and a drum grading screen (model: GS1530) to remove Impurities such as sand, stone, ironware, and braids. The rice under the drum grading sieve passes through the sand-water separator as part of the rice flour, the rice on the sieve is further pulverized by a hammer mill (model: PC-0604), and the rice under the sieve and the rice on the sieve are crushed The particle size of the powder is to pass through a 25-mesh sieve. After mixing, the material and dust and other impurities are separated by a CZT cyclone separator to obtain rice flour that passes through a 25-mesh sieve.

[0066] (2) Preparation of liquefied mash: mix rice flour and water evenly to form a slurry, wherein the material-water ratio of rice flour is 1:2, adjust the pH to 5.3 with sulfuric acid, and control ...

Embodiment 3

[0072] (1) Pretreatment of rice crushing: The aged grains with a storage period of 5 years are passed through a specific gravity stone remover (model: TQSF200), an electromagnetic iron remover (model: RCDB), and a drum grading screen (model: GS1530) to remove Impurities such as sand, stone, ironware, and braids. The rice under the drum grading sieve passes through the sand-water separator as part of the rice flour, the rice on the sieve is further pulverized by a hammer mill (model: PC-0604), and the rice under the sieve and the rice on the sieve are crushed The particle size of the powder is to pass through a 25-mesh sieve. After mixing, the material and dust and other impurities are separated by a CZT cyclone separator to obtain rice flour that passes through a 25-mesh sieve.

[0073] (2) Preparation of liquefied mash: mix rice flour and water evenly to form a slurry, wherein the material-water ratio of rice flour is 1:2, adjust the pH to 5.3 with sulfuric acid, and control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com