Building external wall powder paint and preparation method thereof

A technology for powder coatings and architectural exterior walls, applied in the field of architectural coatings, can solve the problems of application restrictions on architectural exterior walls, poor coating adhesion, and difficulty in pan-alkali, etc., and achieve simple preparation and construction, good chemical resistance, and decorative properties. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

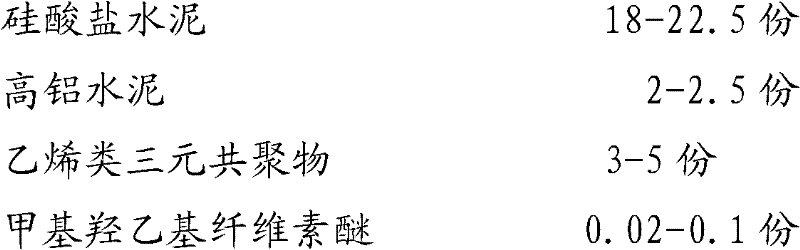

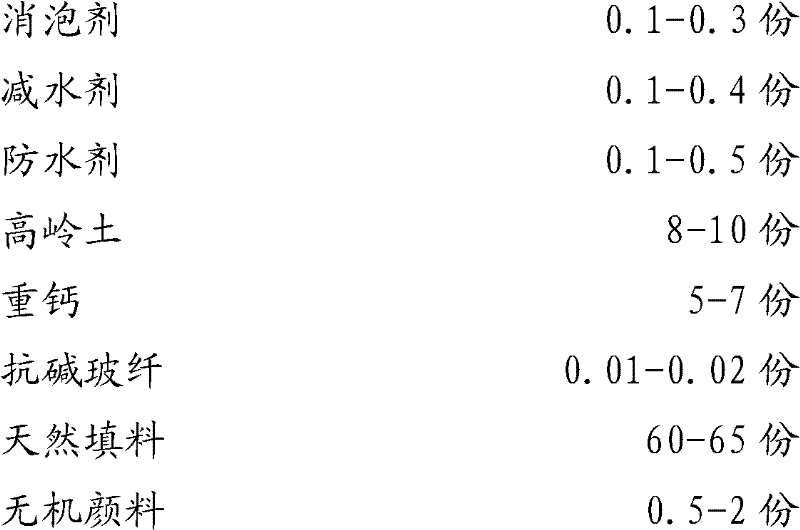

Method used

Image

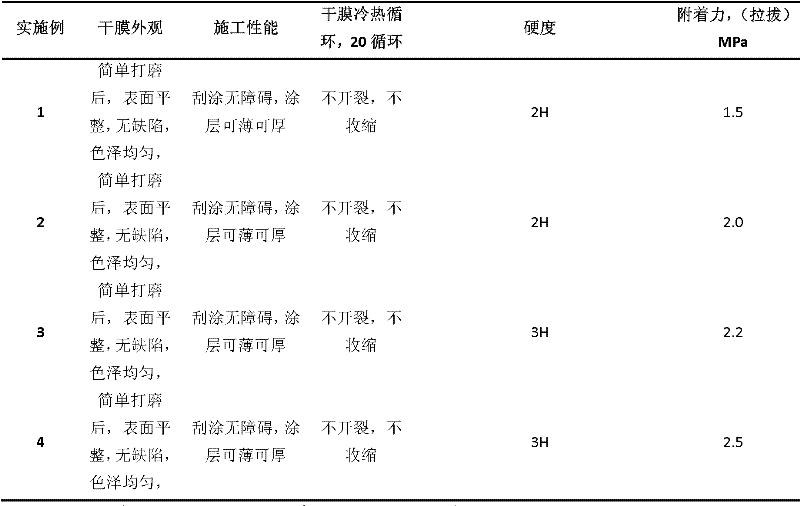

Examples

Embodiment 1

[0026] In the single-mix dry powder mortar mixer, add 18 parts of white Portland cement, 2 parts of high alumina cement, 3 parts of ethylene terpolymer, 0.02 parts of methyl hydroxyethyl cellulose ether, 0.1 part of defoamer , 0.1 part of water reducing agent, 0.1 part of waterproofing agent, 8 parts of kaolin (800 mesh), 7 parts of heavy calcium (400 mesh), 0.01 part of alkali-resistant glass fiber, 20 parts of river sand (20 mesh), 30 parts of river sand ( 40 mesh), 25 parts of river sand (80 mesh) and 0.5 part of iron yellow, stir and mix evenly, then discharge and pack.

Embodiment 2

[0028] In the single-mix dry powder mortar mixer, add 18 parts of white Portland cement, 2 parts of high alumina cement, 5 parts of ethylene terpolymer, 0.02 part of methyl hydroxyethyl cellulose ether, 0.1 part of defoamer , 0.2 parts of water reducing agent, 0.5 parts of waterproofing agent, 8 parts of kaolin (800 mesh), 7 parts of heavy calcium (400 mesh), 0.01 part of alkali-resistant glass fiber, 20 parts of river sand (20 mesh), 30 parts of river sand ( 40 mesh), 25 parts of river sand (80 mesh), 0.5 part of iron yellow, stir and mix evenly, then discharge and pack.

Embodiment 3

[0030] In the single-mix dry powder mortar mixer, add 22.5 parts of white Portland cement, 2.5 parts of high alumina cement, 3 parts of ethylene terpolymer, 0.02 parts of methyl hydroxyethyl cellulose ether, and 0.3 parts of defoamer , 0.2 parts of water-reducing agent, 0.1 part of waterproofing agent, 8 parts of kaolin (800 mesh), 7 parts of heavy calcium (400 mesh), 0.01 part of alkali-resistant glass fiber, 20 parts of river sand (20 mesh), 30 parts of river sand ( 40 mesh), 20 parts of river sand (80 mesh) and 0.5 part of iron yellow are stirred and mixed evenly, and then packed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com