Patents

Literature

30results about How to "Improve the insulation resistance value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

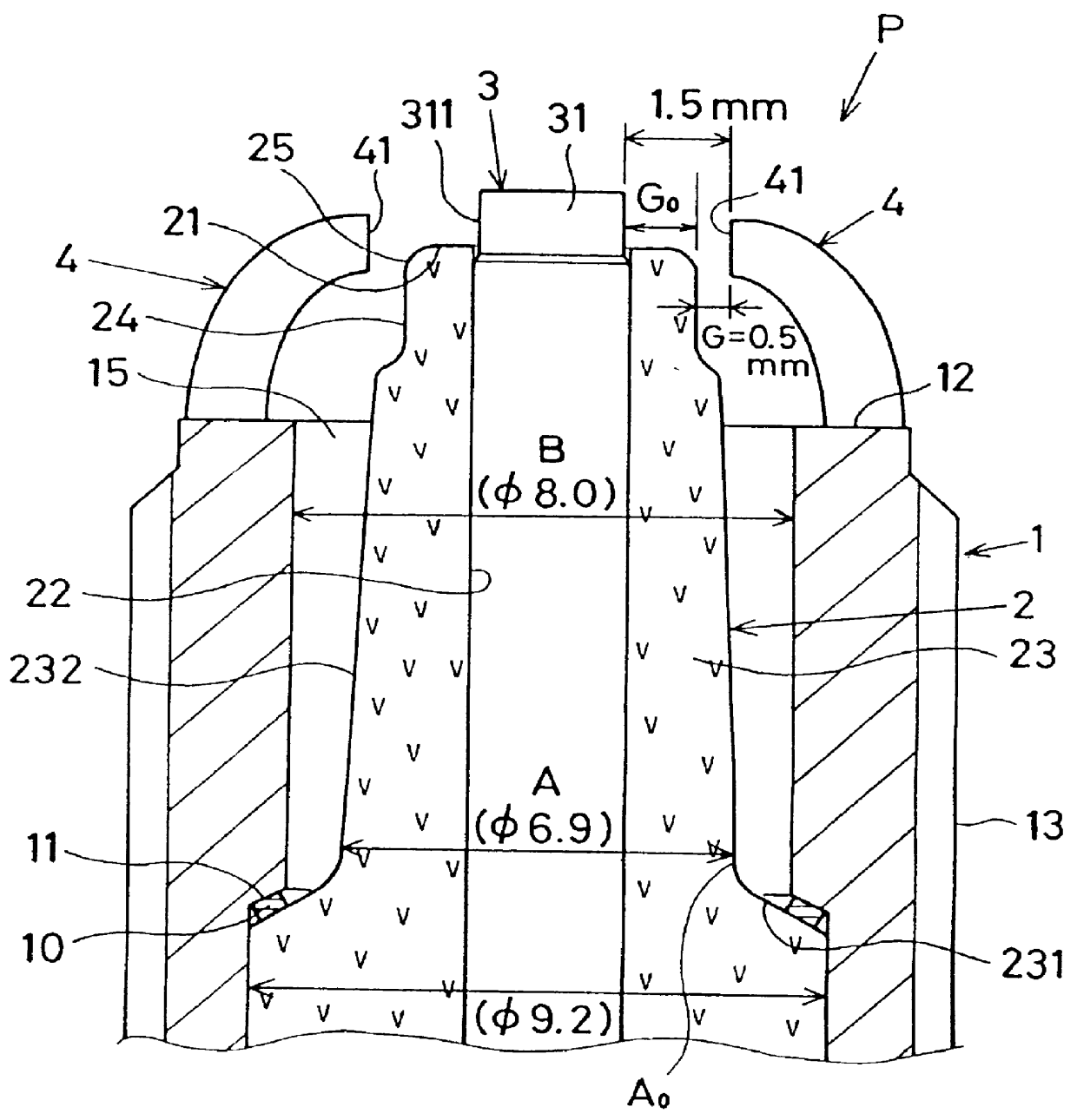

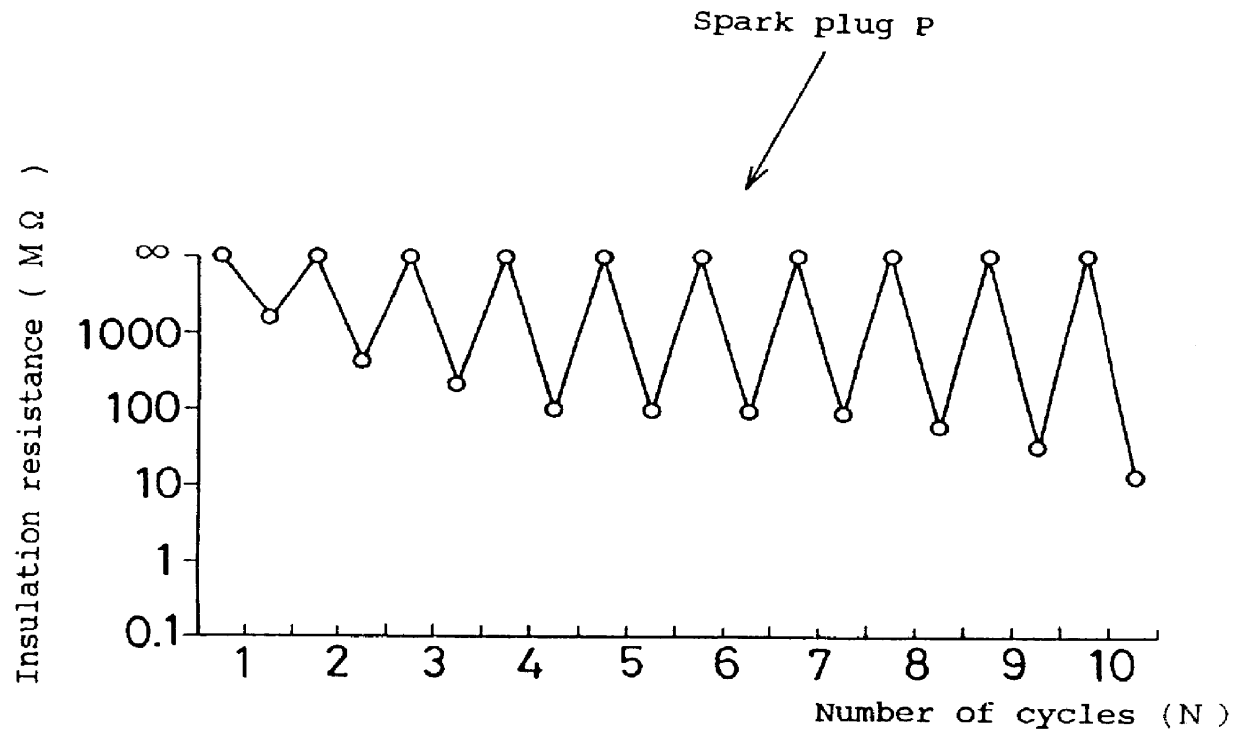

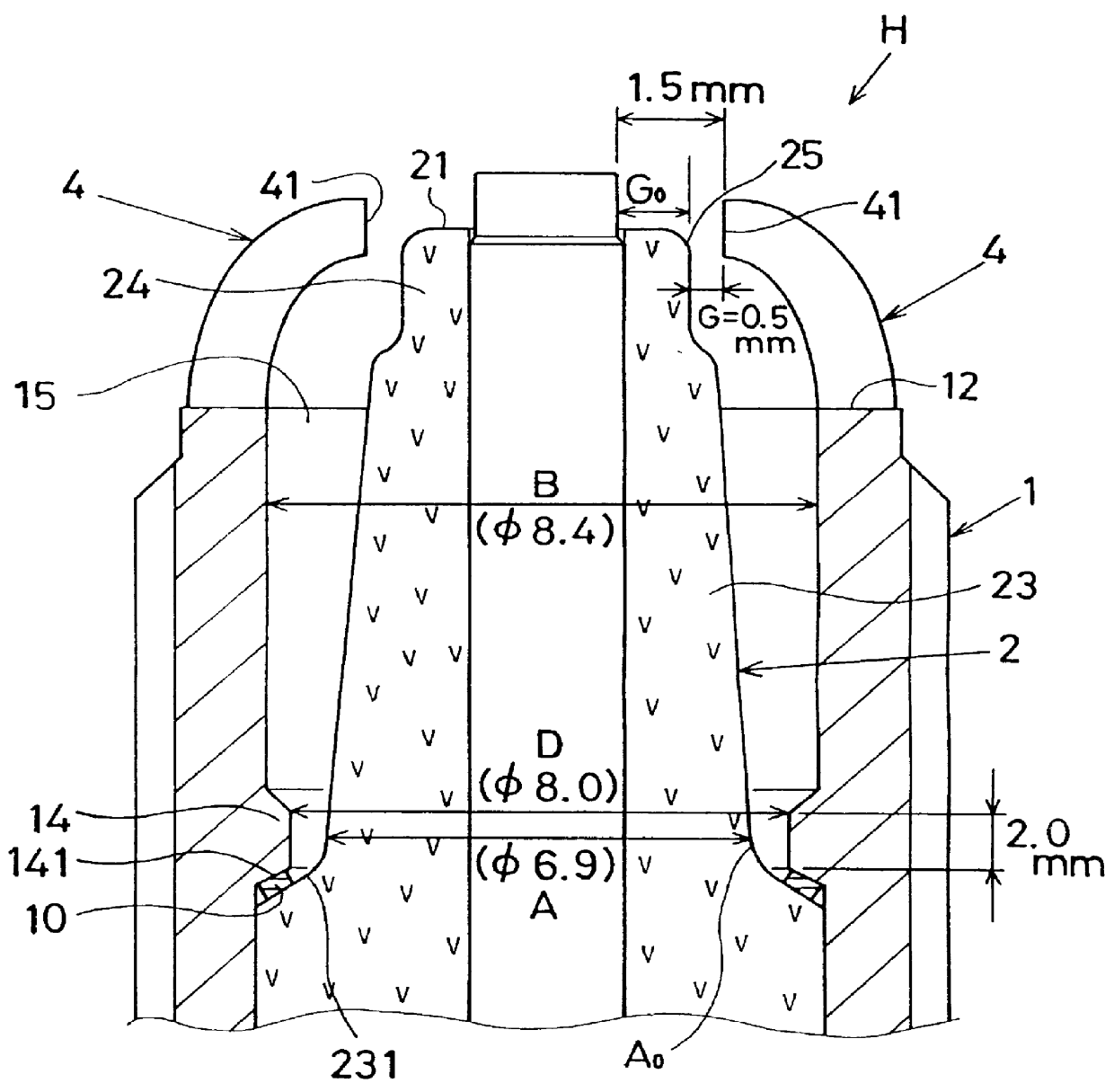

Lateral electrode type spark plug with geometrical relationships with ground electrode

InactiveUS6091185AEffective protectionHigh insulation resistanceSparking plugsFuel injection apparatusNoseEngineering

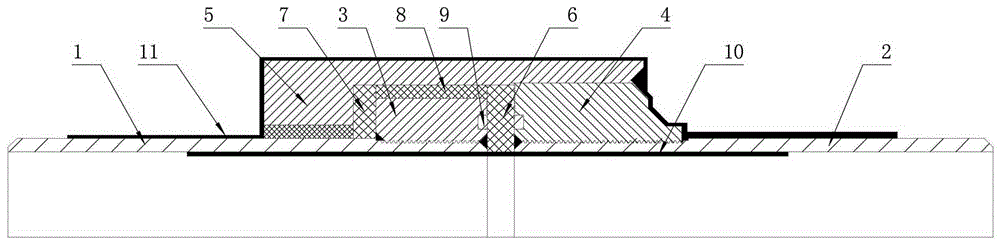

In a spark plug, a cylindrical metal shell (1) is provided whose inner wall has a rear section and a front section to respectively serve as a diameter-increased section and a diameter-decreased section with a seat portion (1) as a boundary therebetween. An insulator (2) is fixedly placed within the metal shell (1) so that a front end surface (21) of the insulator (2) extends beyond a front end surface (12) of the metal shell (1) with a shoulder portion (231) of an insulator nose (23) engaged against the seat portion (11) of the metal shell (1) by way of a packing (10). A center electrode (3) is fixedly placed within an axial bore (22) of the insulator (2), A ground electrode (4) is connected to the front end surface (12) of the metal shell (1), and bent so that a front end surface (41) of the ground electrode (4) opposes an outer surface (311) of the center electrode (3). The outer surface (311) and a front end surface (31) of the center electrode (3) are provided to respectively serve as a firing portion so as to form a spark discharge gap (Go) with the front end surface (41) of the ground electrode (4), the front end surface (41) of the ground electrode (4) forming an air gap (G) with an outer surface (25) of the insulator (2) so as to release creeping spark discharges along a front end surface (21) of the insulator (2).

Owner:NGK SPARK PLUG CO LTD

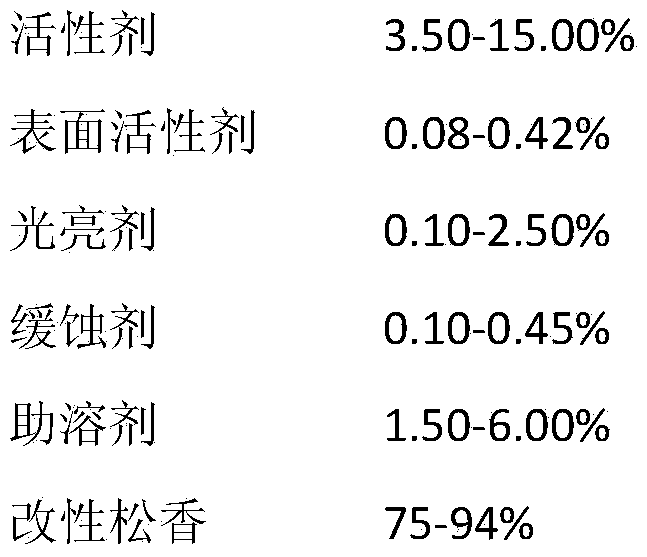

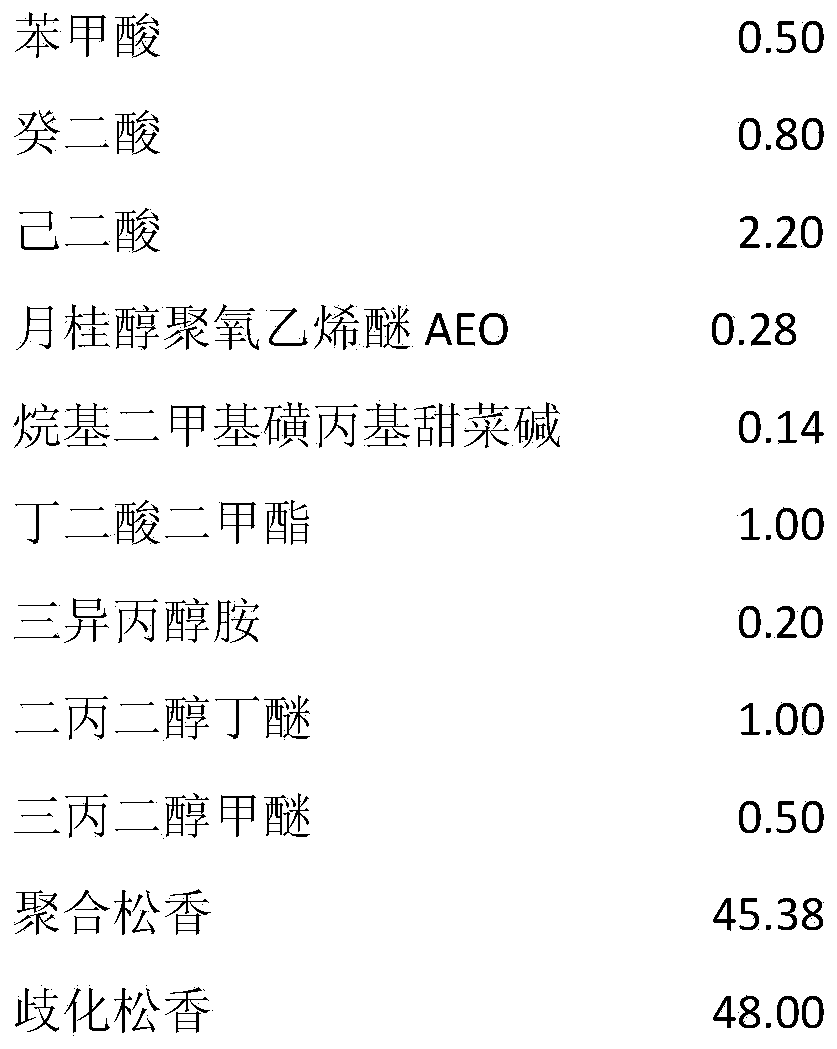

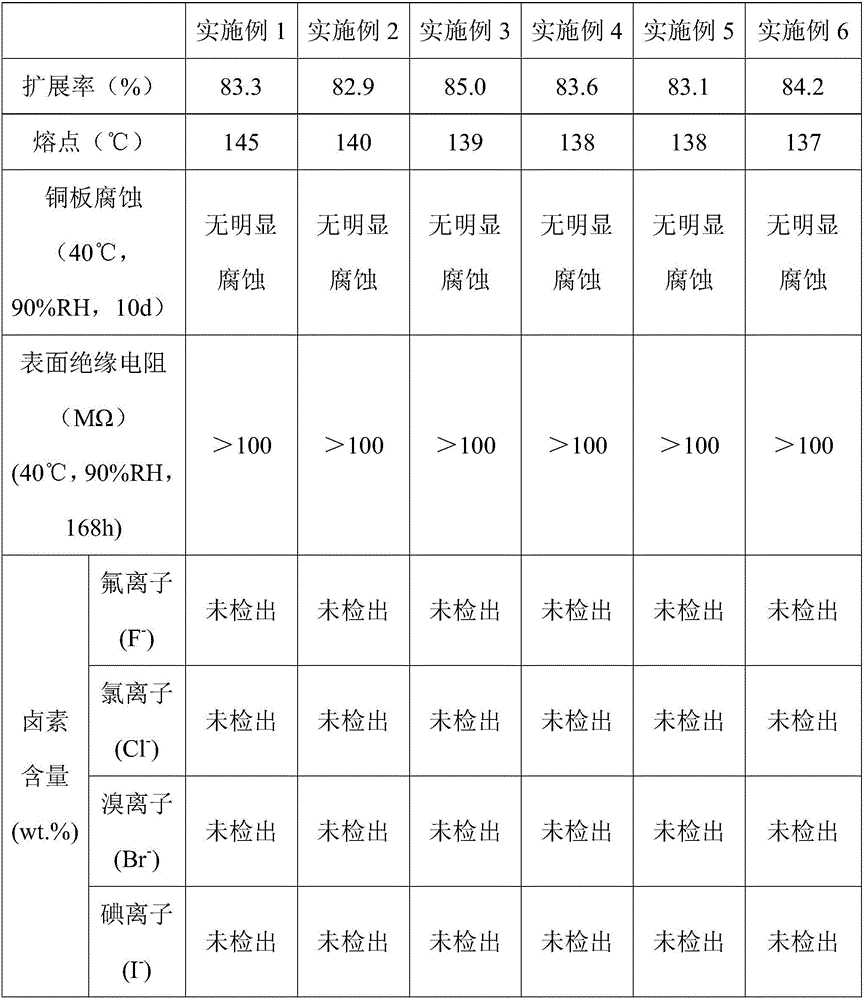

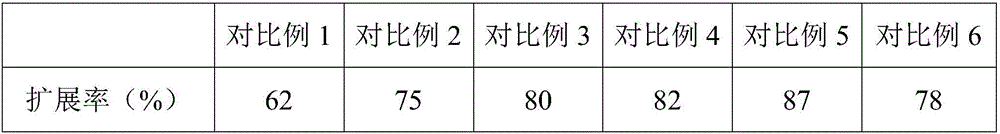

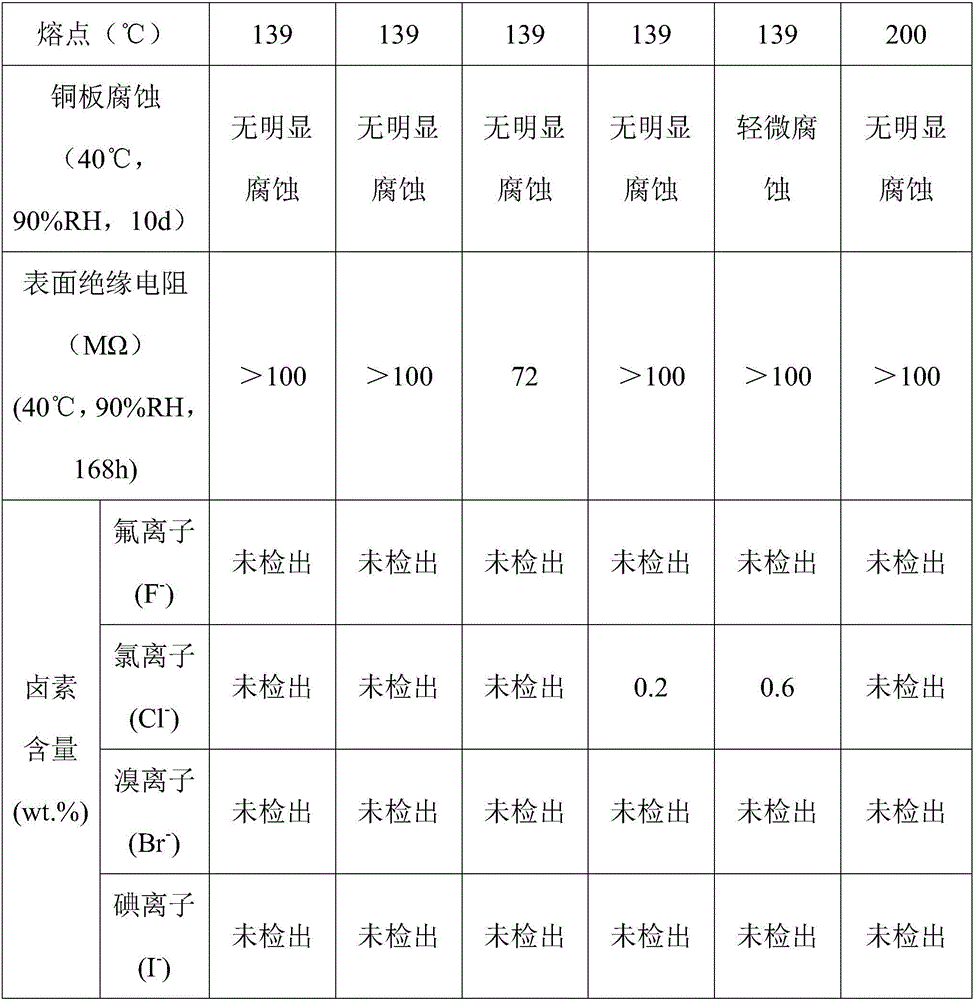

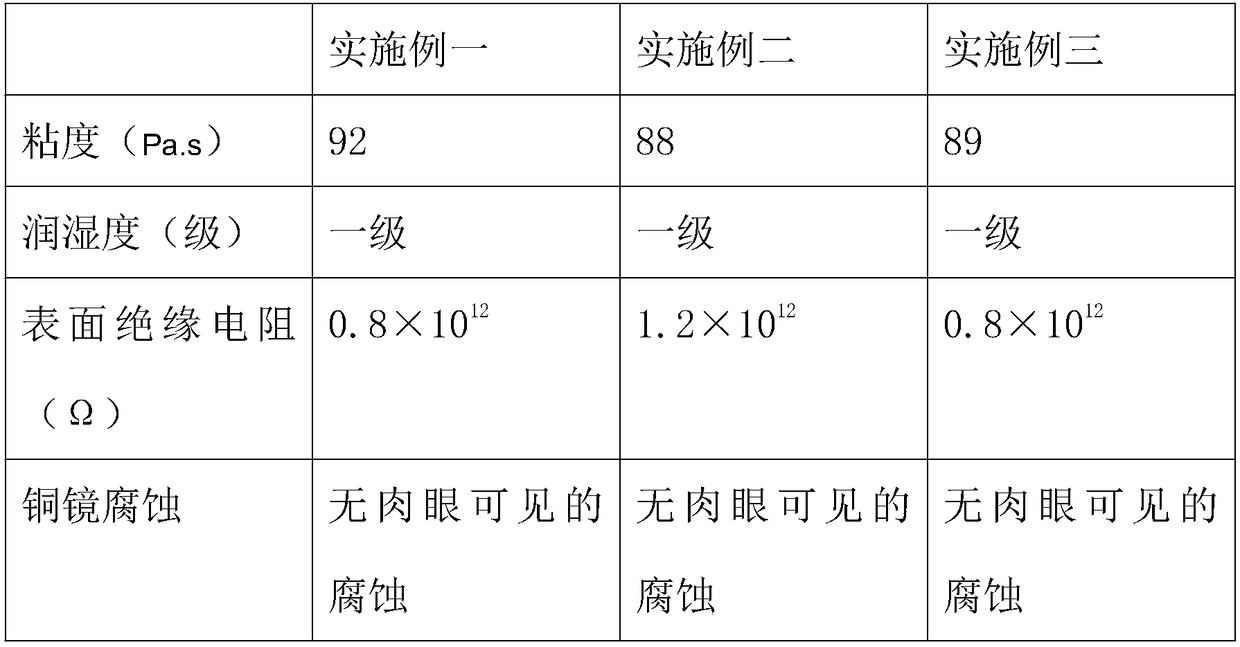

Abietyl-based soldering flux for halogen-free no-clean bright solder wire and preparation method thereof

InactiveCN104070308AIncrease brightnessGood specular reflection abilityWelding/cutting media/materialsSoldering mediaTinningElectricity

The invention discloses an abietyl-based soldering flux for a halogen-free no-clean bright solder wire and a preparation method thereof. The abietyl-based soldering flux comprises, by mass, raw materials including active agent 3.50-15.00%, surface active agent 0.08-0.42%, brightener 0.10-2.50%, corrosion inhibitor 0.10-0.45%, cosolvent 1.50-6.00% and the balance modified rosin. The ingredient proportion in the abietyl-based soldering flux is suitable for manufacture of lead-free solder wires containing the soldering flux in cores, and the soldering flux can be used for automatic welding or manual soldering iron welding. When the solder wire welding is adopted, the process stability is good, tinning speed is high, the splashing amount is small, the defects including continuous tinning, solder skips, insufficient solder, icicles and the like in the welding process can be decreased, welding spots are bright and full after welding, residues are few, the corrosivity is low, cleaning is not needed, and the surface electrical insulation property is excellent after the welded solder wires are placed for a long period of time.

Owner:SOUTH CHINA UNIV OF TECH

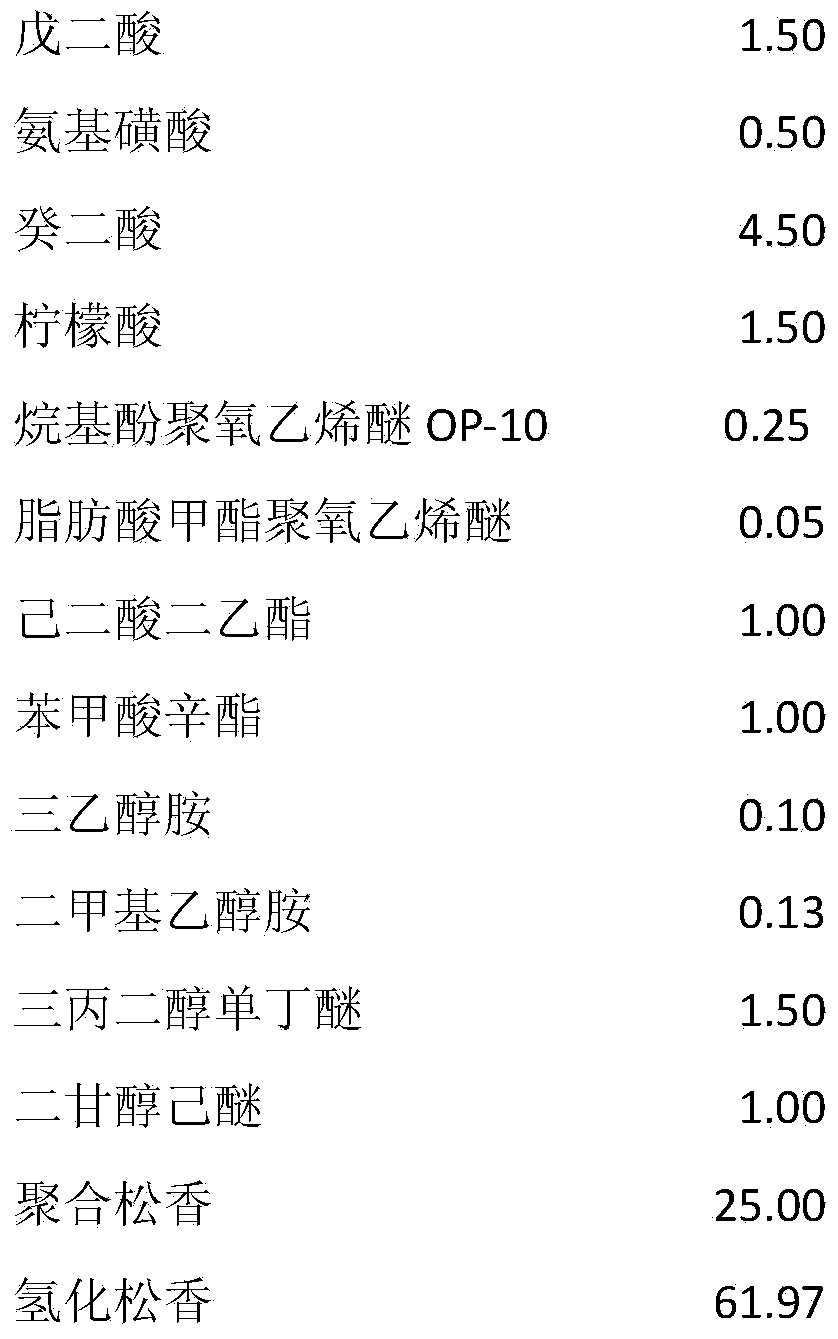

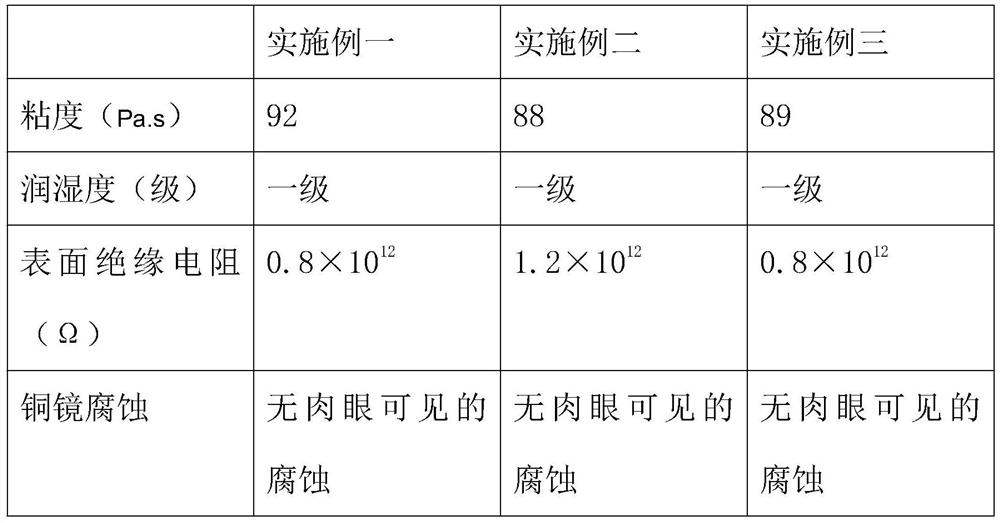

No-wash halogen-free flux and low-temperature soldering tin wire

InactiveCN106271217AHigh activityImprove the insulation resistance valueWelding/cutting media/materialsSoldering mediaHalogenSurface-active agents

The invention discloses a no-wash halogen-free flux and low-temperature soldering tin wire. The no-wash halogen-free flux is prepared from, by weight, 20-30% of film forming matter, 40-70% of solvent, 2-7% of activator, 0.1-1% of surface active agent, and 0.5-3% of additive. The no-wash halogen-free flux does not contain halogen compounds and is environmentally friendly; the composition proportion of the film forming matter, the solvent, the activator, the surface active agent, and the additive in the raw materials is adjusted, so that the activity of the no-wash halogen-free flux is high, less residue is left after welding, a cleaning process after welding is not required, and the insulation resistance value of components and parts after welding is remarkably increased. In addition, compared with traditional lead-free solder, the low-temperature soldering tin wire has lower melting point, practicability of manual welding is high, welding spots are smooth and attractive, and the low-temperature soldering tin wire can be widely used in welding of thermal sensing elements.

Owner:工业和信息化部电子第五研究所华东分所

Environmental-friendly water-soluble flux and preparation method thereof

InactiveCN101850483AImprove the insulation resistance valueReduce corrosionWelding/cutting media/materialsSoldering mediaPolyvinyl alcoholSolvent

The invention relates to an environmental-friendly water-soluble flux which is matched with lead-free solder; the environmental-friendly water-soluble flux comprises anhydrous citric acid, DL-malic acid, triethanolamine, modified polyvinylalcohol, polymethyl acrylate, vinyl acetate-ethylene copolymer powder, hydroxyethyl methyl cellulose ether, surfactant, benzotriazol, phenol and mixed solvent; the anhydrous citric acid, the DL-malic acid, the triethanolamine, the modified polyvinylalcohol, the polymethyl acrylate, the vinyl acetate-ethylene copolymer powder and the hydroxyethyl methyl cellulose ether are prepared into a complex active substance A through microencapsulated coating treatment; and the mixed solvent, the surfactant, the benzotriazol, the phenol, the modified polyvinylalcohol, the polymethyl acrylate and the complex active substance A are uniformly mixed by weight ratio to obtain the environmental-friendly water-soluble flux. The environmental-friendly water-soluble flux can effectively assist lead-free solder, particularly applicable to Sn-Ag-Cu lead-free solder, can enhance the solderability of the lead-free solder, can adapt to the high welding temperature requirement on the lead-free solder, has small action to the corrosion of lead-free solder alloys and little residue after welding, can be cleaned by water, has good welding point quality, clean surface and strong stability, and a dried circuit board has higher insulation resistance value.

Owner:NINGBO YINYANG TIN SOLDER

Spot coating type high-temperature soldering paste and preparation method thereof

InactiveCN102049631ATin evenlyNo size pointConductive pattern formationWelding/cutting media/materialsActive agentAlloy

The invention belongs to the technical field of soldering paste, and particularly relates to high-temperature soldering paste used for spot coating type operation and a preparation method of the high-temperature soldering paste. The high-temperature soldering paste comprises soldering flux and Sn / Pb / Ag tin-based alloy powders distributed in the soldering flux; the soldering flux includes the following components by weight percentage: 30 to 40 percent of polymerized rosin, 8 to 15 percent of hydrogenated rosin, 2 to 4 percent of modified hydrogenated castor oil, 2 to 4 percent of hydrogenated castor oil wax, 5 to 6 percent of active agent, 1 to 2 percent of hydroquinone, 1 to 2 percent of ethylene bis stearamide, and solvent; and the soldering paste adopts a syringe type package and is prepared through vacuumizing defoaming process and other process. The soldering paste has the advantages of stable performance, uniform spot coating, no phenomena of hardening and layering during the storage, no phenomenon of surface crusting on the surface in contact with air, long storage life and service life, good expansion rate and good insulation resistance; and particularly, residues after reflow soldering at the high temperature above 340 DEG C is unsintered and is easy to clean.

Owner:东莞市特尔佳电子有限公司

Water-soluble scaling powder for lead-free solder of tin silver zinc series

InactiveCN101347876AImprove the insulation resistance valueReduce corrosionWelding/cutting media/materialsSoldering mediaSolderabilityWater soluble

The invention relates to a water-soluble soldering flux which is suitable for tin, silver and zinc series lead-free solder. The weight percentage of all the components is as follows: 0.1-22 % of activating agent, 0.1-25 % of wetting agent, 0.1-5% of thixotropic agent, 0.1-2 % of corrosion inhibitor, 0.1-5 % of oxidation inhibitor and solvent for the rest. The invention aims at the problem that the existing soldering flux of leaded solder is not suitable for lead-free solder and provides the water-soluble soldering flux which can be effectively matched with lead-free solder, especially applicable to tin, silver and zinc series lead-free solder; the water-soluble soldering flux can improve wettability, antioxidant ability and solderability of lead-free solder, can meet the requirements of welding temperature of lead-free solder, and causes little corrosion to lead-free solder alloy; postwelding residue is little and can be washed away by water; welding spots have good quality, smooth surfaces and strong stability; a dried circuit board has high insulation resistance value.

Owner:TIANJIN UNIV

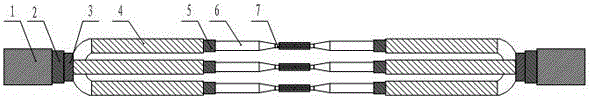

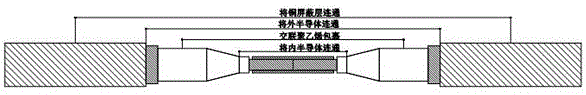

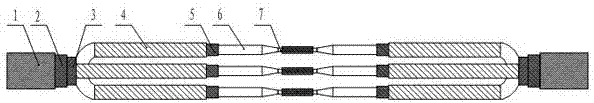

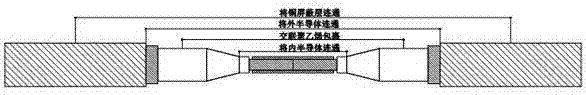

Docking method of 10kV crosslinked polyethylene cable

InactiveCN106848990AWaterproofImprove moisture resistanceSoldered/welded conductive connectionsConnections effected by permanent deformationInsulation layerButt joint

The invention relates to a docking method of a 10 kV crosslinked polyethylene cable. The docking method comprises the specific steps of firstly aligning two sections of cables which need to be in butt joint, stripping cable outer protective sleeves, steel armor layers and inner protective layers in sequence from all ports, and taking down cable filling materials; sleeving one end of the cable with a radioactive heat shrink tube for use after cable butt joint manufacturing is completed; then stripping copper shielding layers and semi-conductive layers in sequence from all the ports; measuring the length of a copper pressed connecting tube which is connected with the cable cores, adopting 1 / 2 of the length of the cable core and adding 5 mm on the length, which is a basis that main insulation parts of the cables which needs to be stripped are exposed out of the conductive cores, according to the length, stripping cable main insulation layers from the ports, cutting the main insulation fractures into pencil tip shapes with the length of 60 mm, and making an inner semi-conductive layers with the length of 5mm exposed; connecting the conductive cores; finally using the sleeved outer protective sleeve radioactive heat shrinkage tube to conduct uniform covering and heat shrinkage on the outer protective sleeve at the middle joint. Compared with a traditional method, the docking method of the 10 kV crosslinked polyethylene cable has superior moisture resistance, waterproofness and insulating properties.

Owner:刘国晓

High temperature soldering paste special for semiconductors

ActiveCN108544140AImprove self-leveling propertiesReduce the frequency of scraping solder pasteWelding/cutting media/materialsSoldering mediaActive agentPolyamide

The invention relates to high temperature soldering paste special for semiconductors. The high temperature soldering paste comprises scaling powder and tin-based alloy powder, and the scaling powder comprises the following raw materials including a thixotropic agent, an active agent, polymerized rosin, hydrogenated rosin and the balance organic solvent; the thixotropic agent comprises the following raw materials including ethylene bis stearamide, high-performance amide wax powder, polyamide modified hydrogenated castor oil derivatives and the balance butyl carbitol-terpilenol mixture; and theactive agent comprises the following raw materials including decyl tetradecanoic acid, a fluorinated surfactant, 2-ethylimidazole and the balance butyl carbitol-terpilenol mixture. According to the high temperature soldering paste, the components in the thixotropic agent are adjusted, and therefore the self-leveling characteristic of the soldering paste is improved, the soldering paste scrapping frequency of an operator is reduced, the repeated soldering paste adhering coincidence is improved, the welding wettability is improved, the rudimental insulation resistance value after welding is improved, and the client product electrical property is improved.

Owner:东莞市仁信电子有限公司

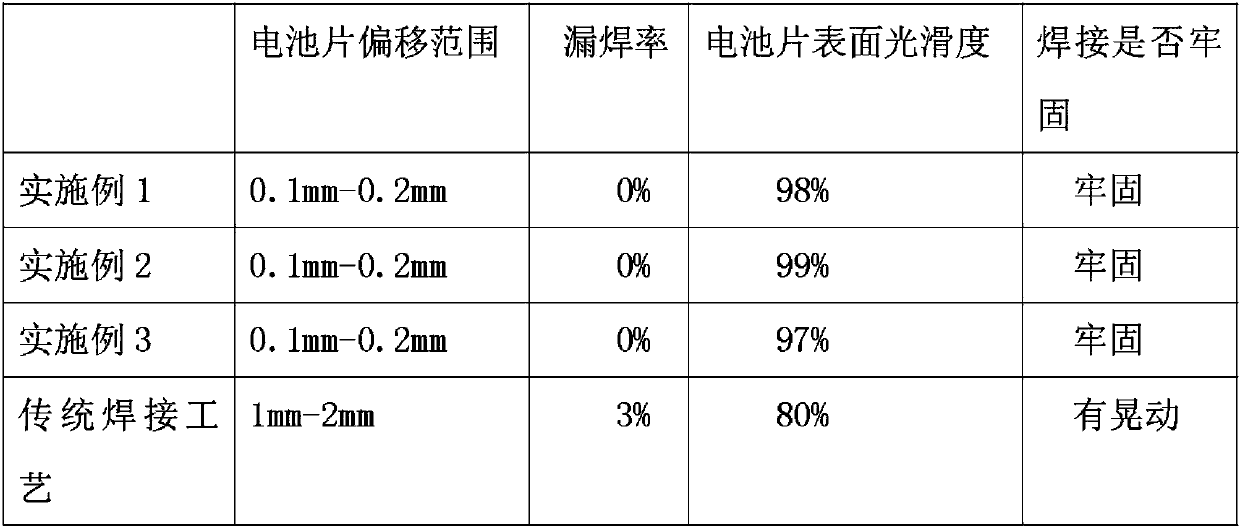

Battery piece welding process for photovoltaic power generation transverse connection assembly

InactiveCN111112789AGood welding performanceGood insulation resistance valueWelding/soldering/cutting articlesMetal working apparatusSolderingBattery cell

The invention discloses a battery piece welding process for a photovoltaic power generation transverse connection assembly. The battery piece welding process comprises the following steps of 1, determining the number of battery pieces, checking whether the battery pieces have phenomena such as unfilled corners, cracking and the like, confirming that the battery pieces are complete, and taking andplacing one battery piece with the front side facing upwards; 2, pretreating interconnection strips; 3, placing one battery piece in the middle of a heating plate, and taking and laying a group of solder strips on a main grid line of the battery piece; 4, carrying out single welding on the battery pieces; 5, performing pretreatment before series welding; and 6, performing series welding on the battery pieces subjected to single welding. According to the battery piece welding process, welding is carried out on the single battery pieces, and then the multiple groups of welded battery pieces arewelded in series, so that the welding effect is good, the phenomenon of welding deviation or unstable contact caused by direct series welding can be avoided, and the welding quality is improved; and the interconnection strips are placed in a soldering flux with a reasonable proportion to be soaked, so that the wettability during welding can be improved.

Owner:JETION SOLAR HLDG

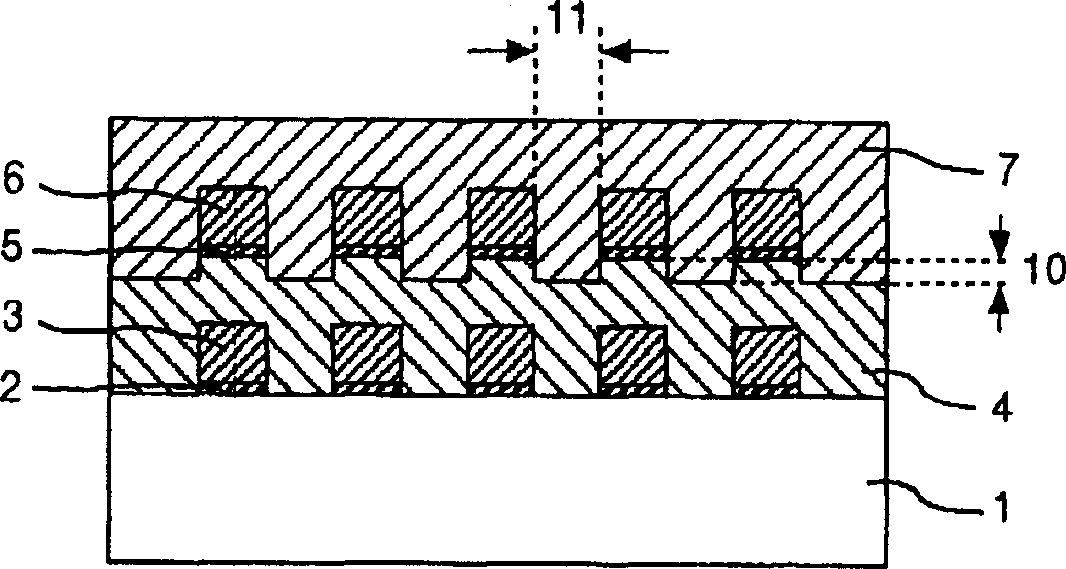

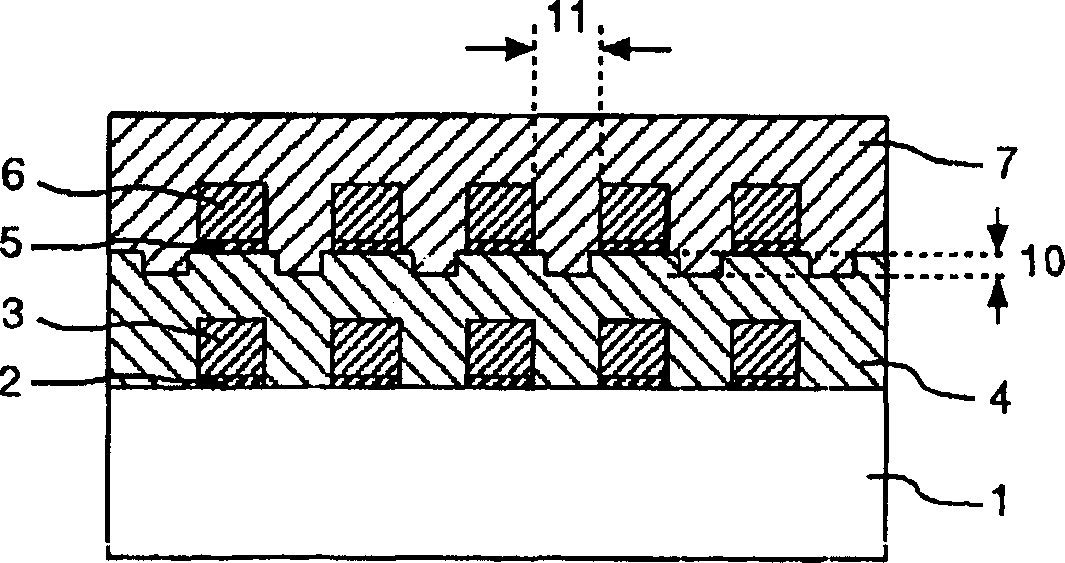

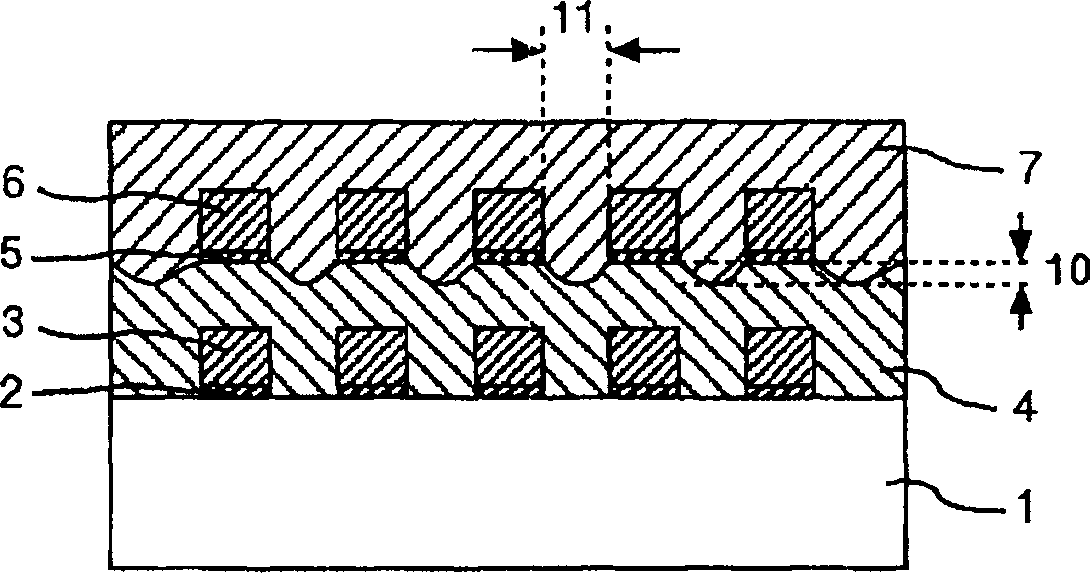

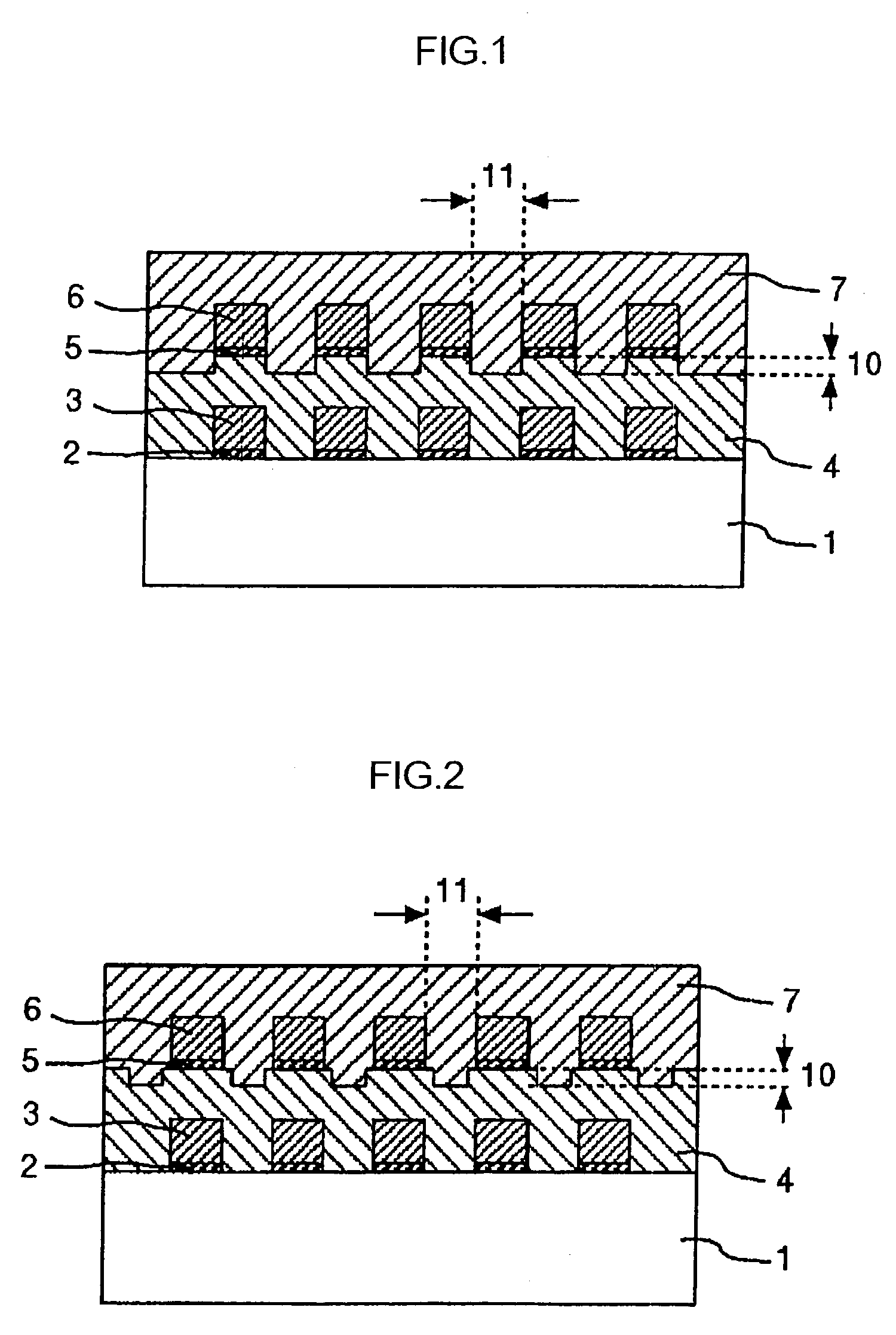

Distributing base board and electronic device using it

InactiveCN1461181AImprove the insulation resistance valuePrinted circuit detailsSemiconductor/solid-state device detailsElectrical conductorIon migration

The present invention provides a printed wiring board which has high insulation resistance between wirings and is unlikely to cause failures such as leakages or short circuits, attributable to ion migration even in high temperatures and highly humid environments. The printed wiring board has a circuit comprising a metal conductor on base metal layers created by forming an insulating resin layer 4 on at least one face of an insulating substrate 1 and forming the base metal layers 2 and 5 on the insulating resin layer. In the printed wiring board, at least a part of an upper face of the insulating resin layer existing in spaces 11 between the metal conductors is formed at a position lower than the interface between the base metal layer 5 and the insulating resin layer 4.

Owner:HITACHI LTD

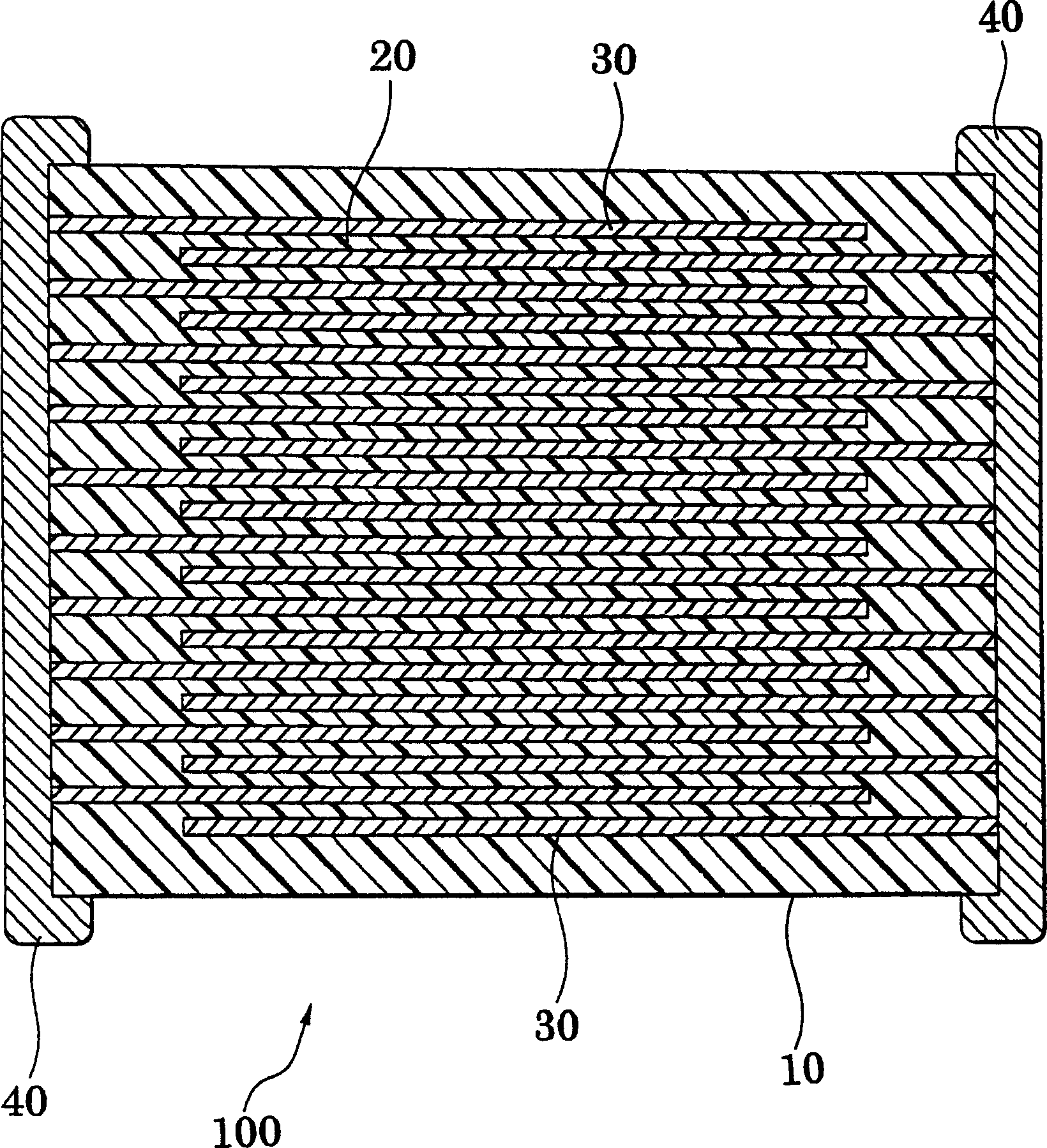

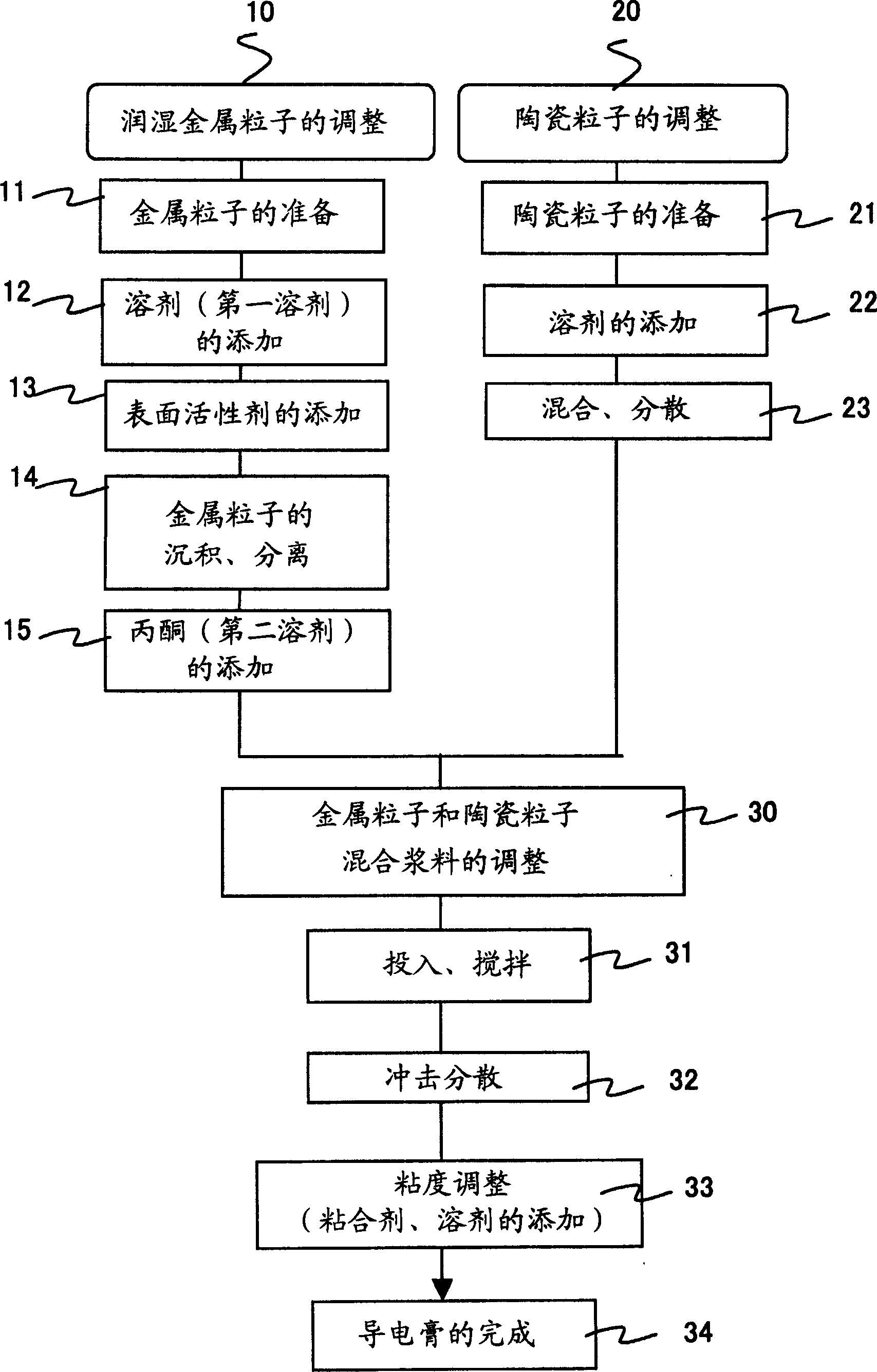

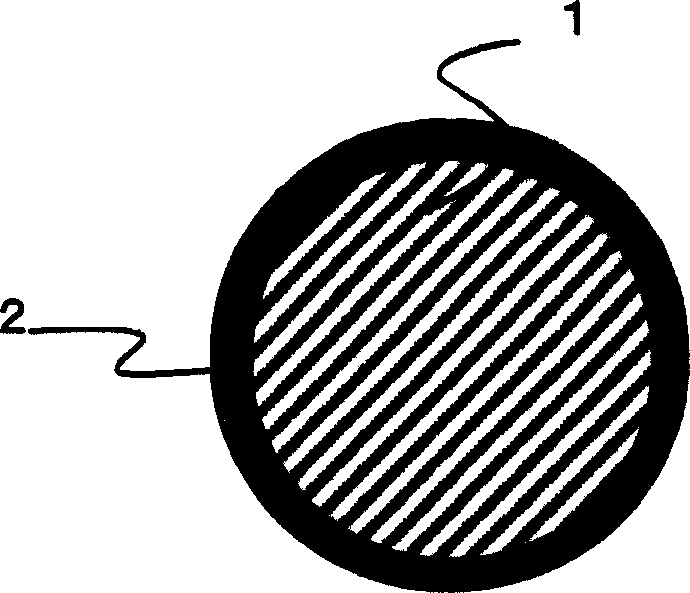

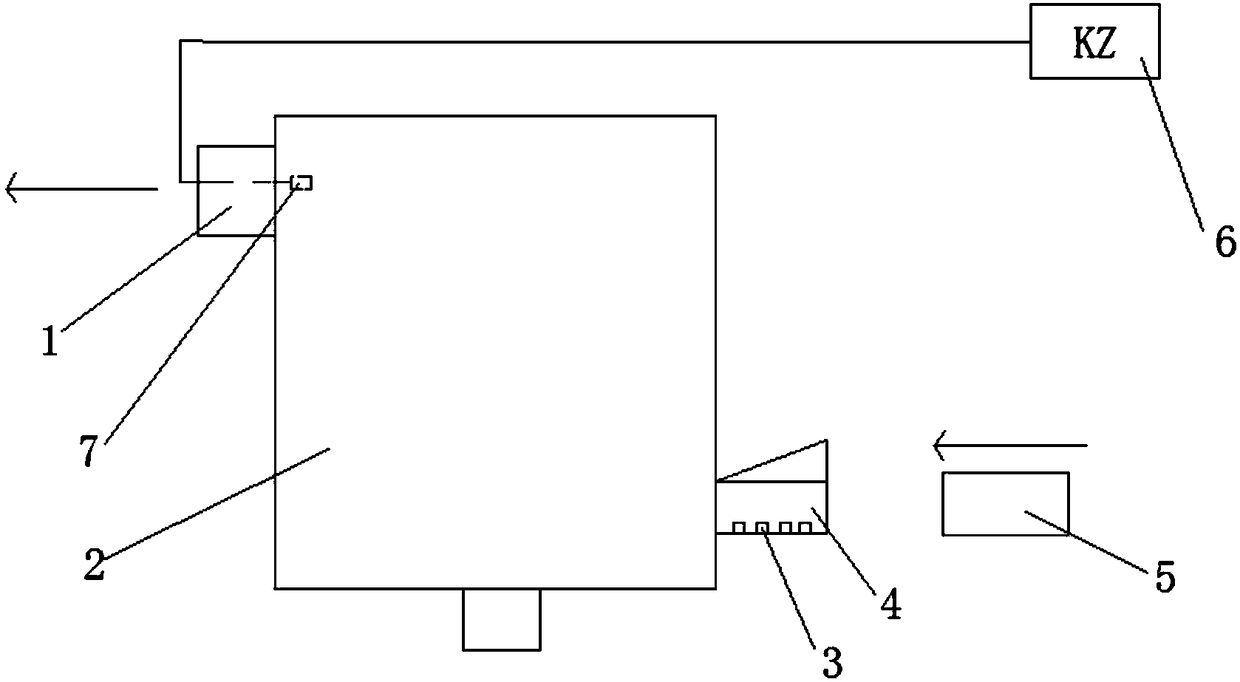

Conductive composition mfg. method and conductive paste mfg. method

InactiveCN1534693AAvoid damageExtend your lifeFixed capacitor electrodesFixed capacitor dielectricConductive pasteSlurry

Owner:TDK CORPARATION

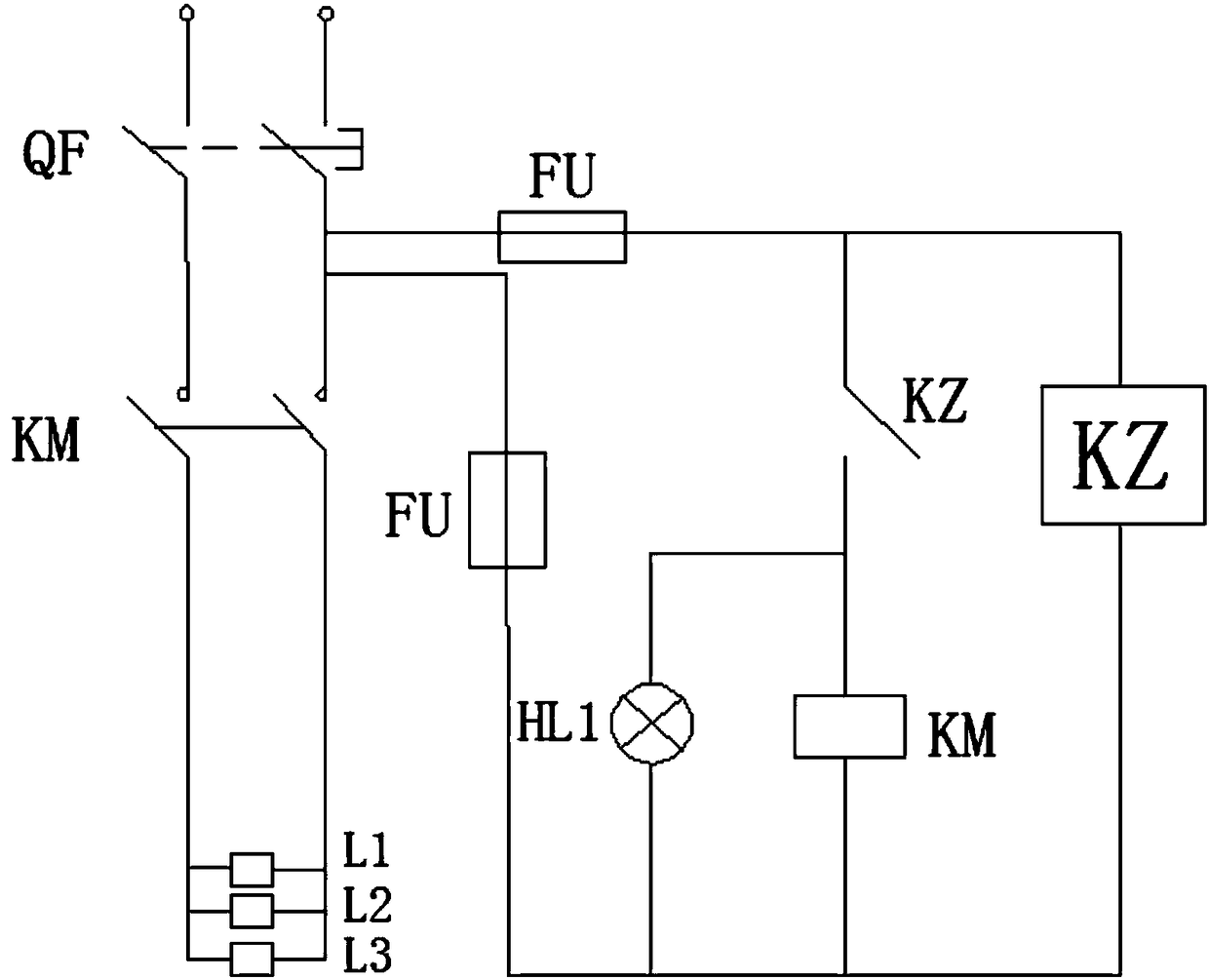

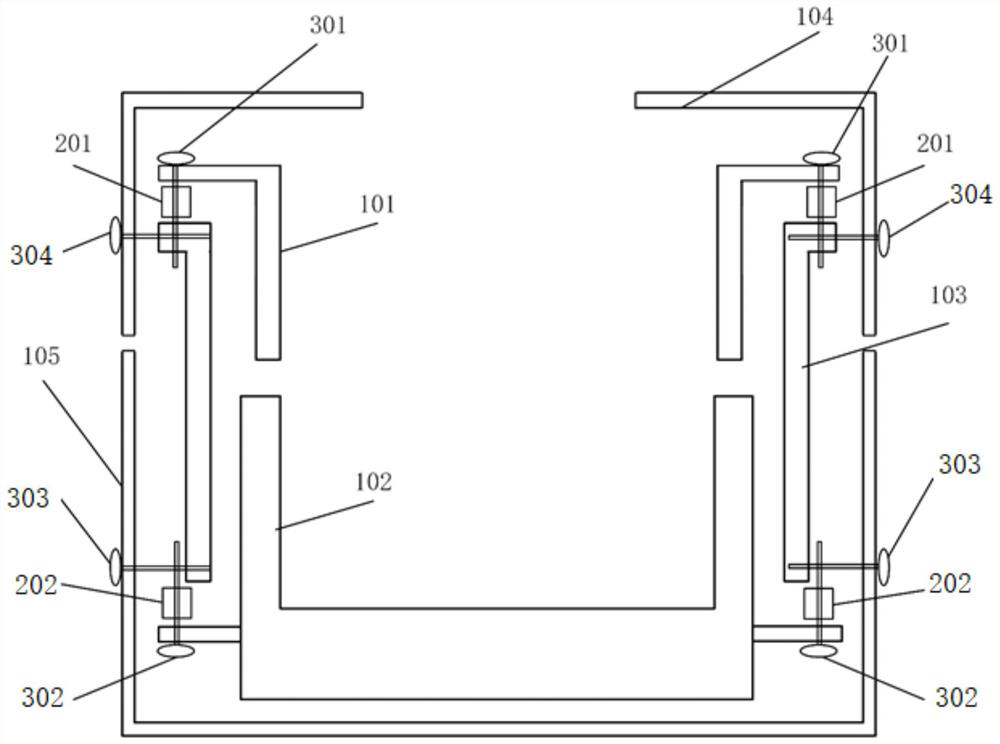

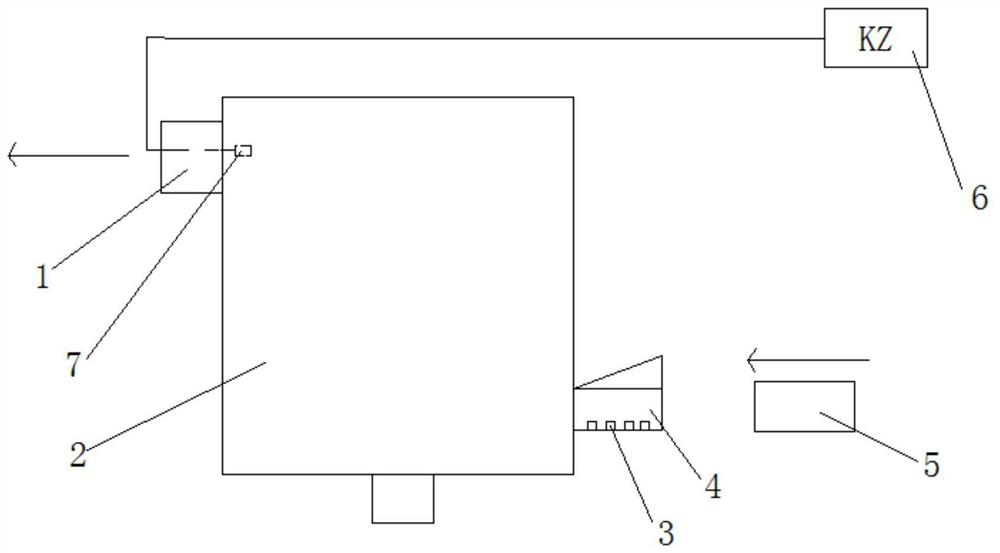

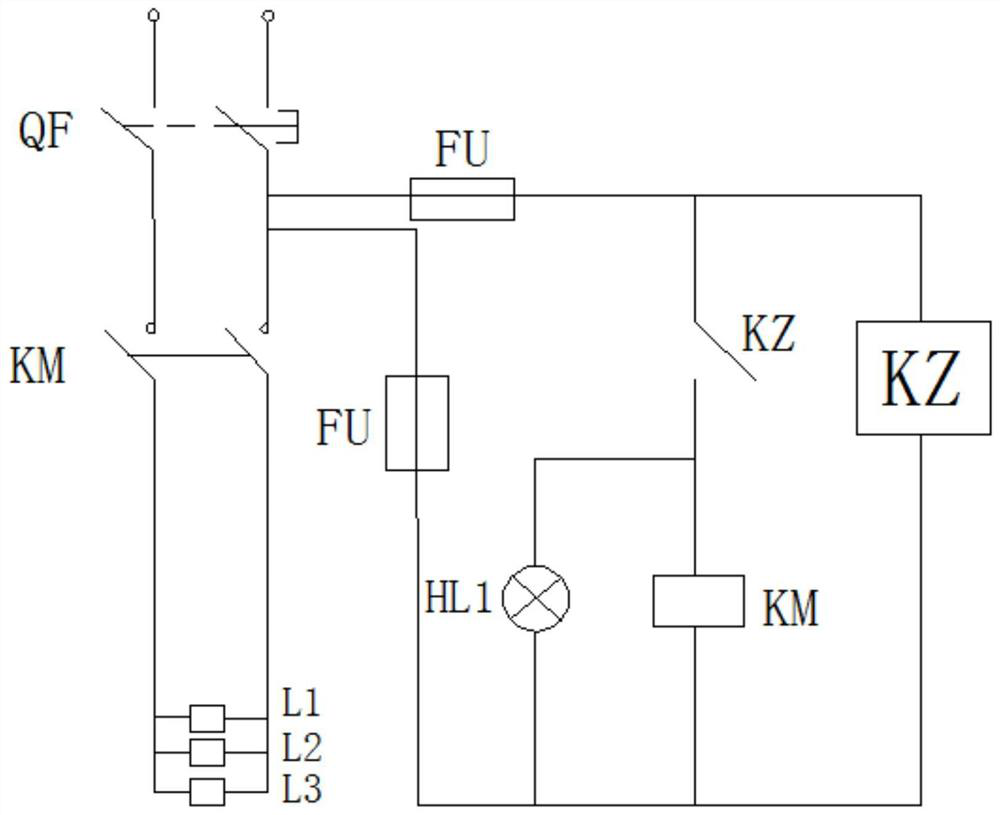

Method for improving insulating property of large motor on site

ActiveCN108539938AImprove insulation performanceHigh insulation resistanceManufacturing dynamo-electric machinesPower flowElectric machine

The invention relates to a method for improving the insulating property of a large motor on site. The method comprises the steps as follows: S010, current drying: a drying power supply is started, andcurrent is applied to winding in the motor from the drying power supply continuously for A h; S020, hot air is introduced from an upper air port of the motor and exhausted from a lower air port afterpassing through the winding in the motor; S030, hot air is introduced from the lower air port of the motor and exhausted from the upper air port after passing through the winding in the motor. Current heating and hot air drying steps are performed on the winding in the motor under the condition that the motor is not disassembled, the inside of the motor is dried, and the insulating property of the motor is further improved.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

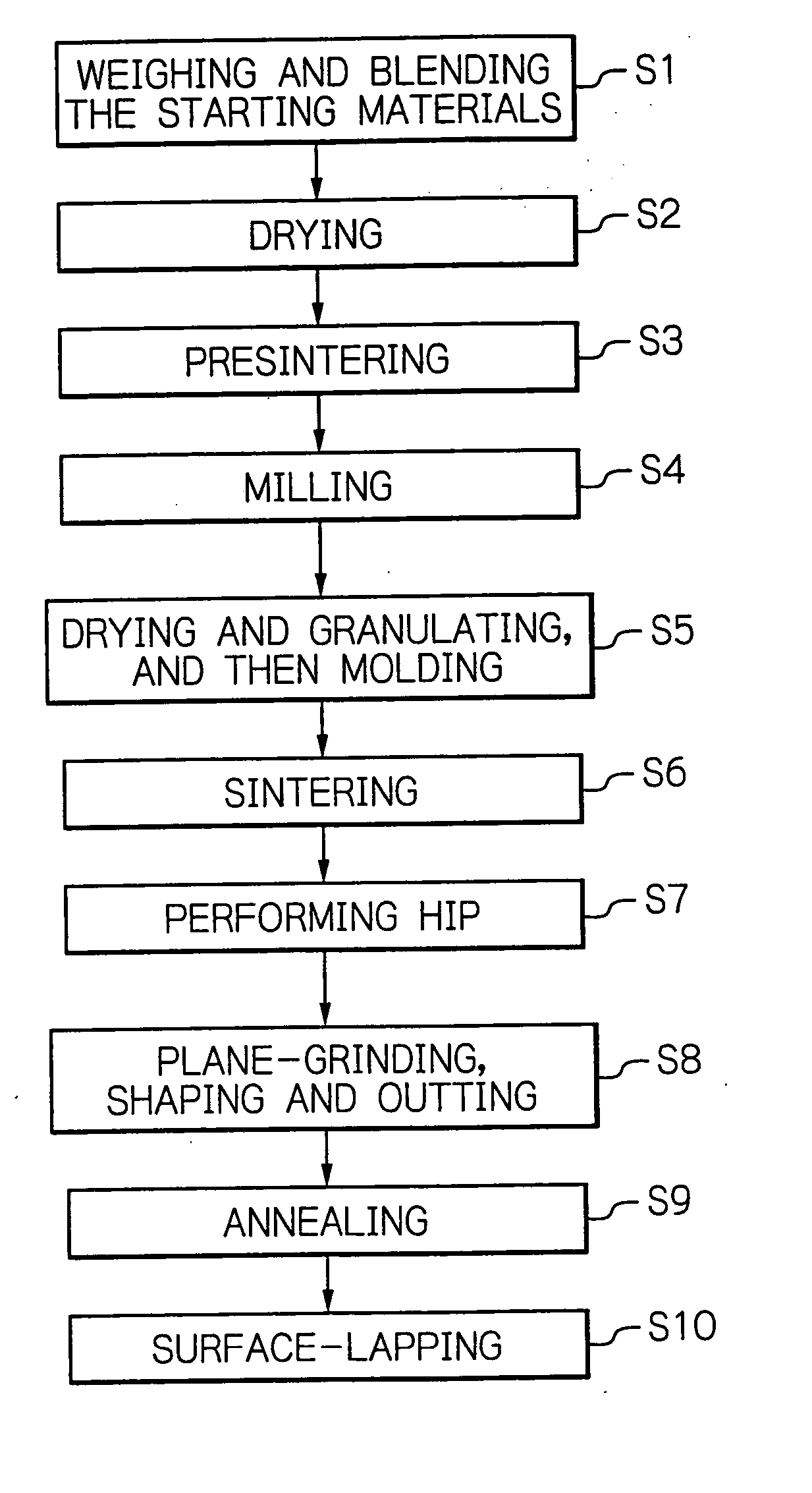

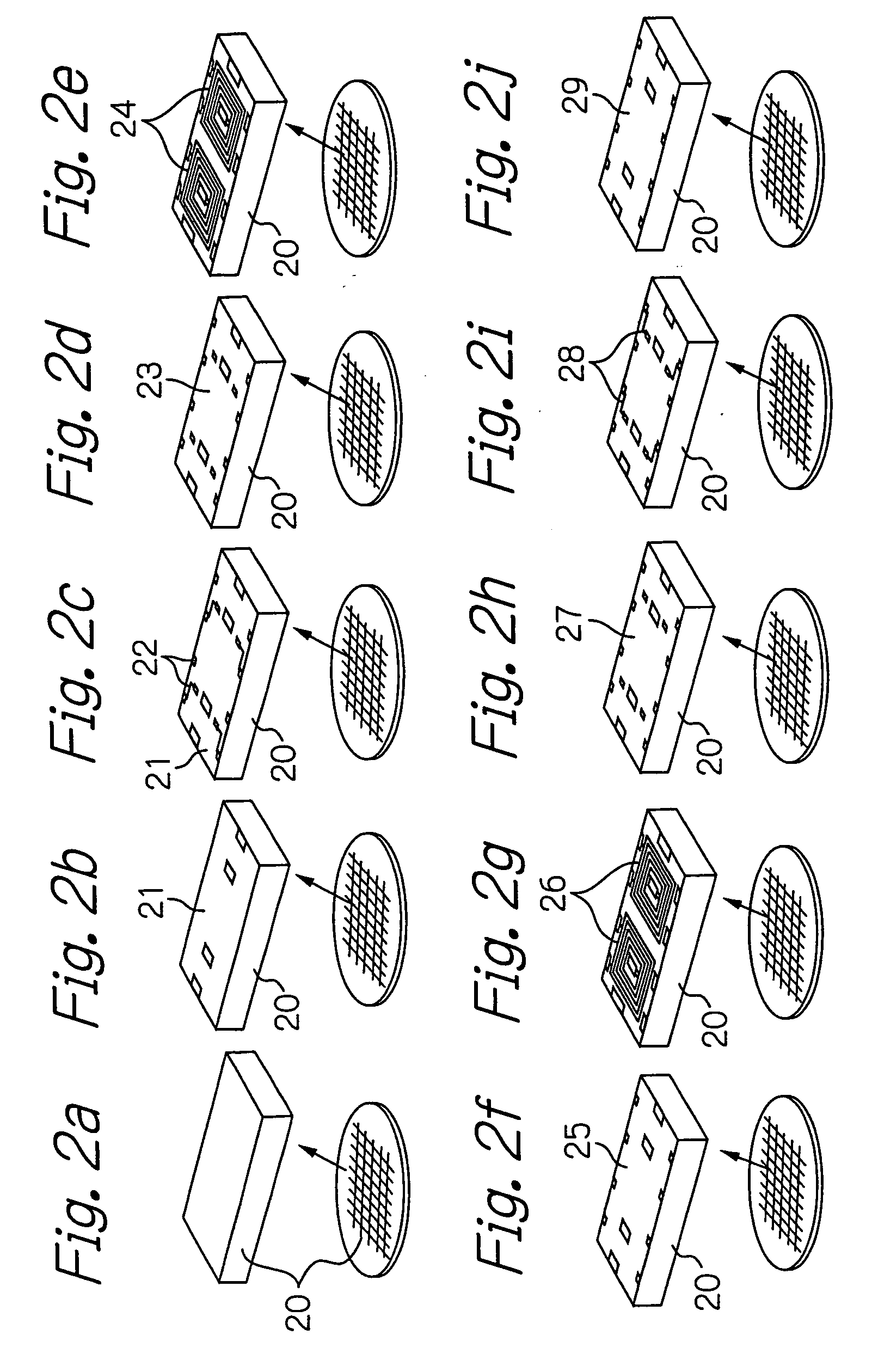

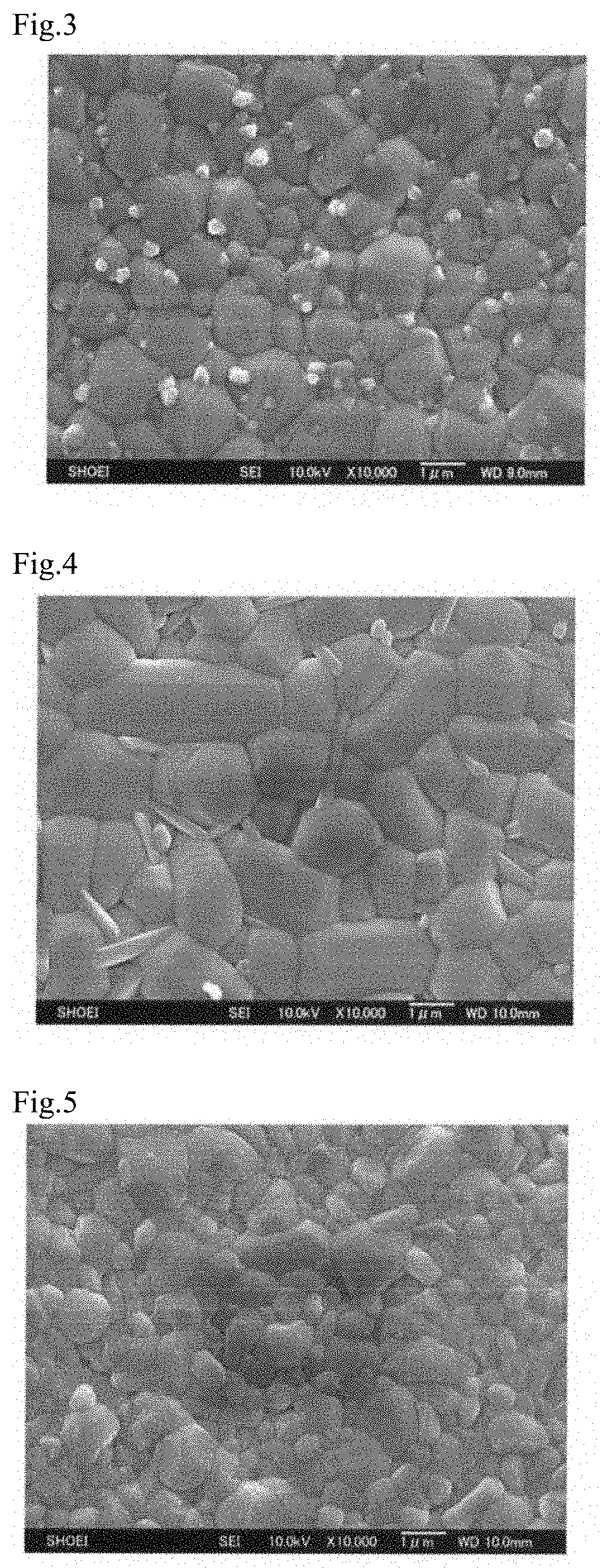

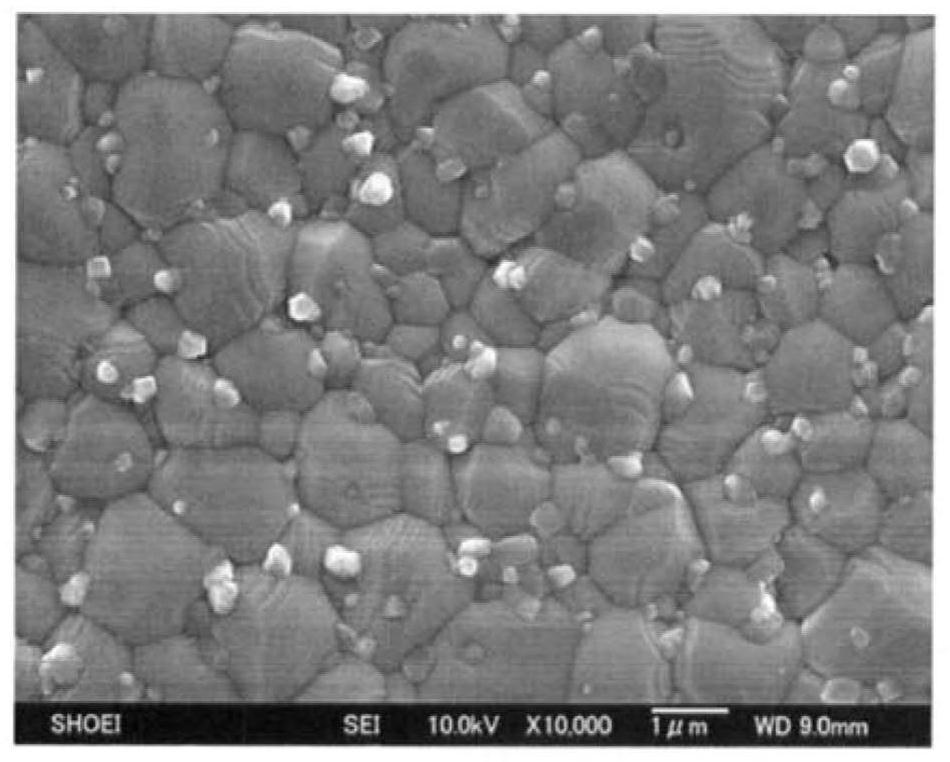

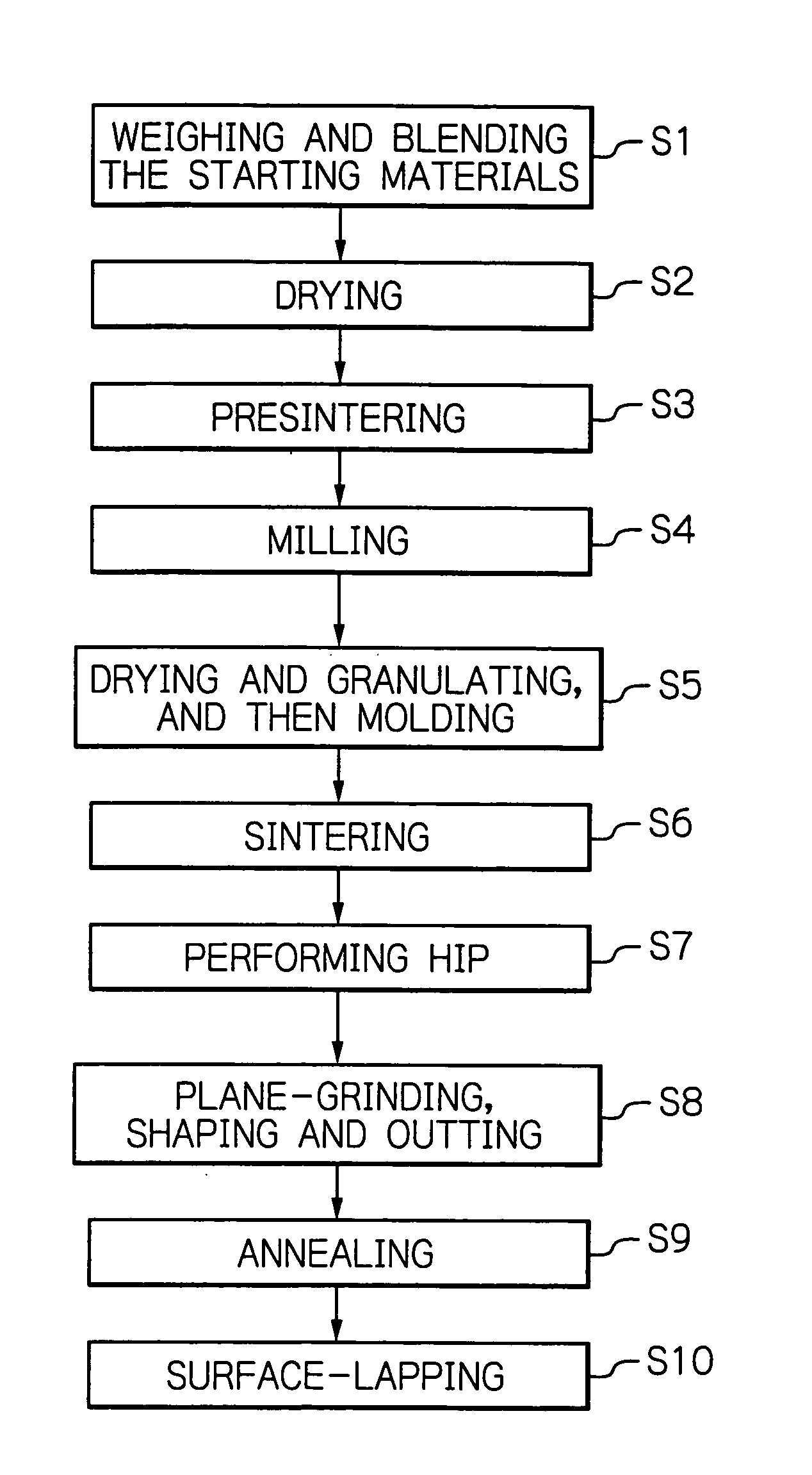

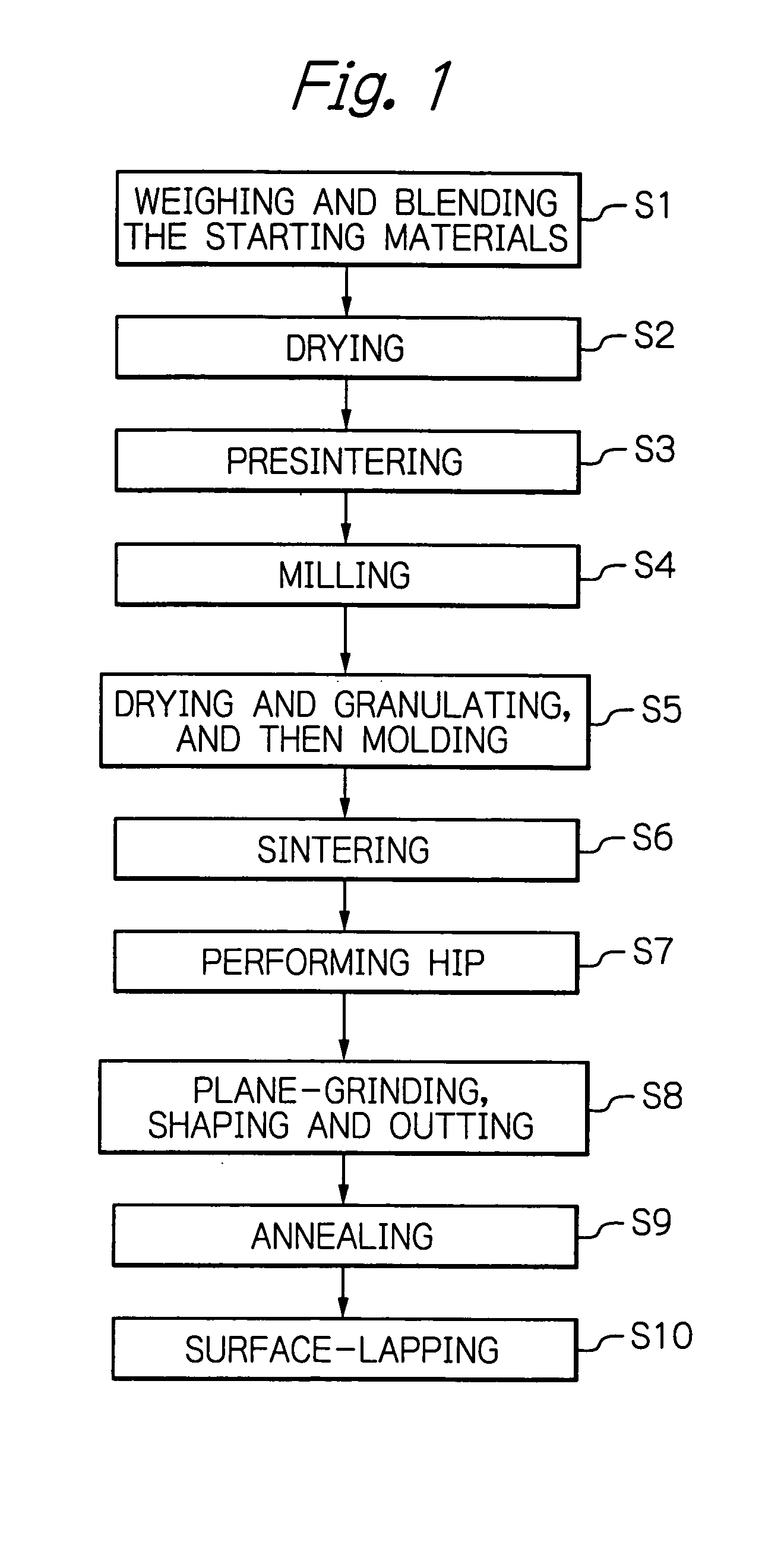

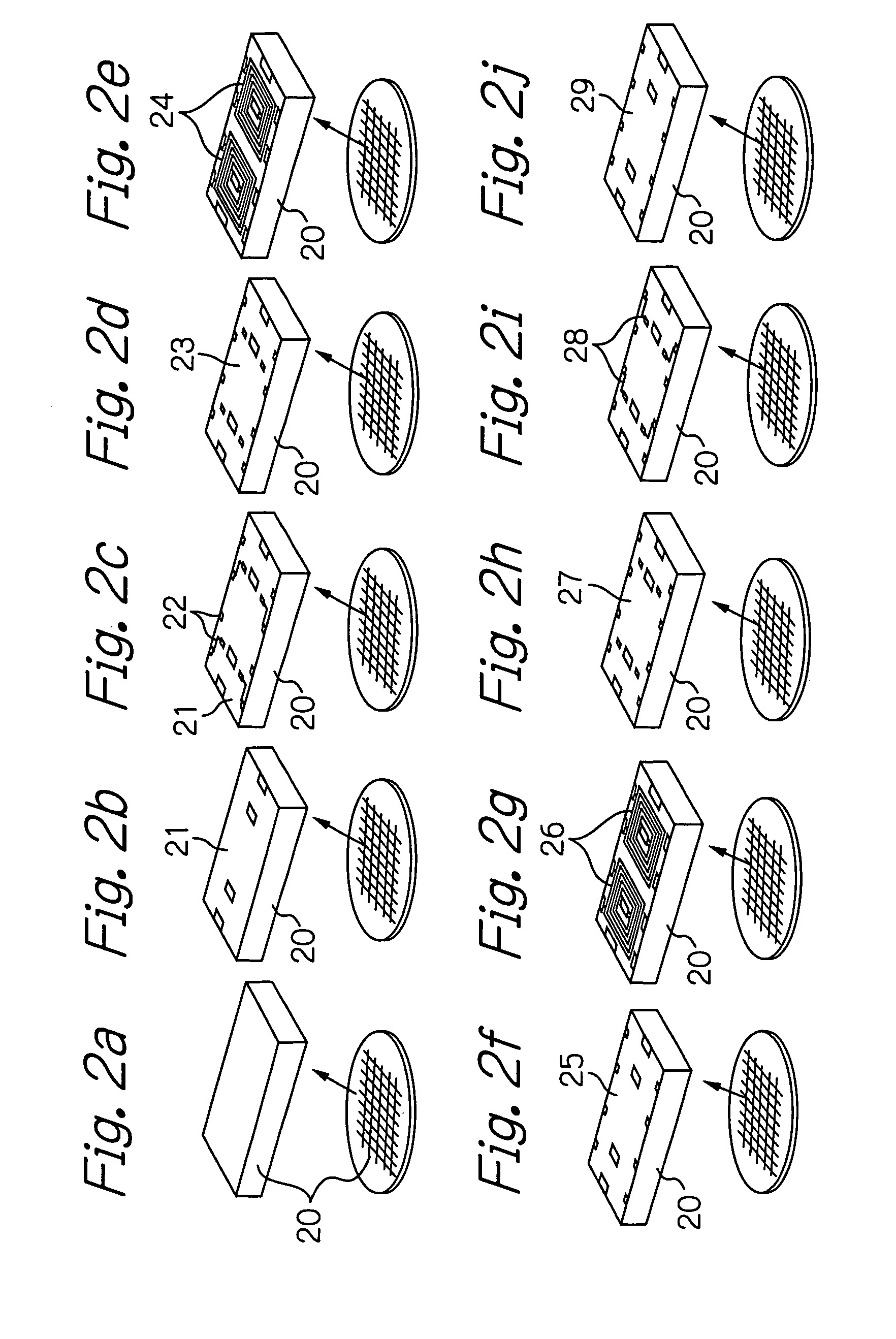

Ferrite substrate for thin-film inductors, thin-film common mode filter using the substrate, thin-film common mode filter array using the substrate and manufacturing method of the substrate

InactiveUS20070077458A1High surface insulation resistanceLess surface-degradationInorganic material magnetismFerroso-ferric oxidesInductorHot isostatic pressing

A ferrite substrate for thin-film inductors is provided by means of blending raw materials to meet a composition of di-iron trioxide (Fe2O3): 40 to 55 molt %, nickel oxide (NiO): 5 to 35 molt, zinc oxide (ZnO): 10 to 40 molt %, and bismuth trioxide (Bi2O3): 150 to 750 ppm, or of Fe2O3: 40 to 55 molt %, NiO: 5 to 35 mol %, ZnO: 10 to 40 mol %, cupric oxide (CuO): 5 to 10 molt, and manganese dioxide (MnO2): 0.5 to 2 molt %, and then molding and sintering the blended material, and applying hot isostatic pressing to the sintered article. A thin-film common mode filter and a thin-film common mode filter array using the ferrite substrate and the manufacturing method of the substrate are also provided.

Owner:TDK CORPARATION

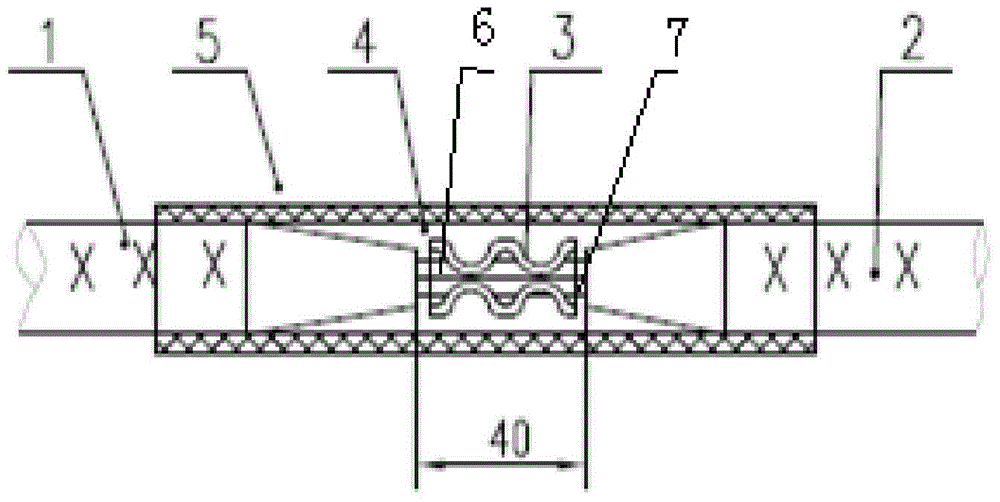

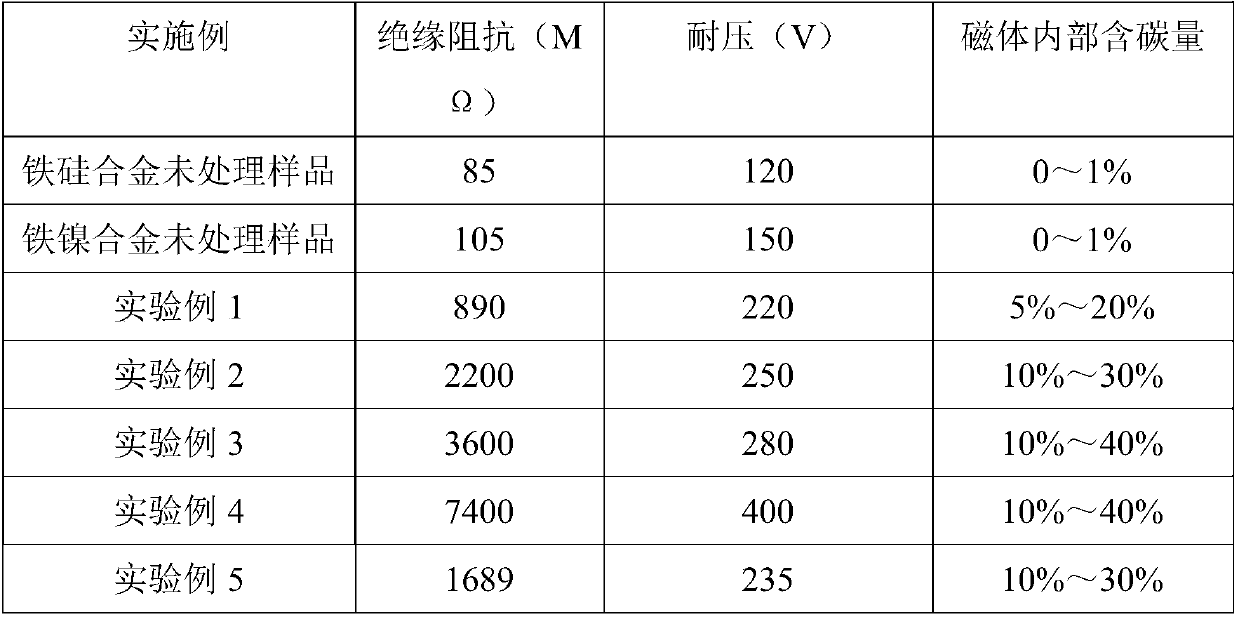

Integrated insulating joint

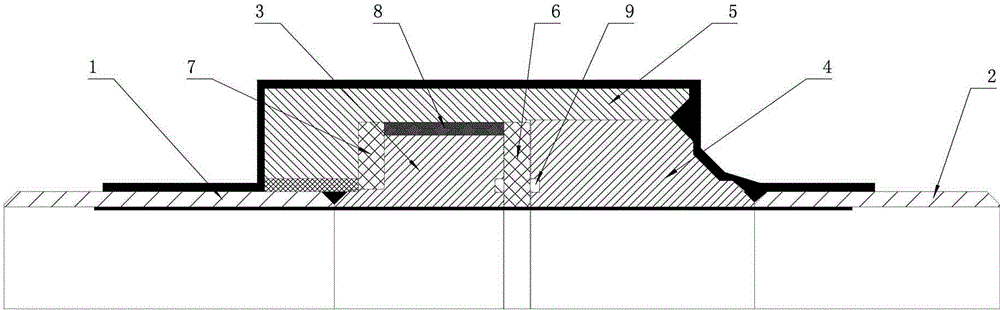

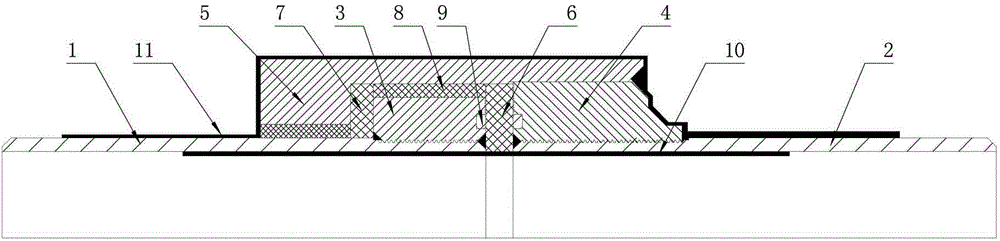

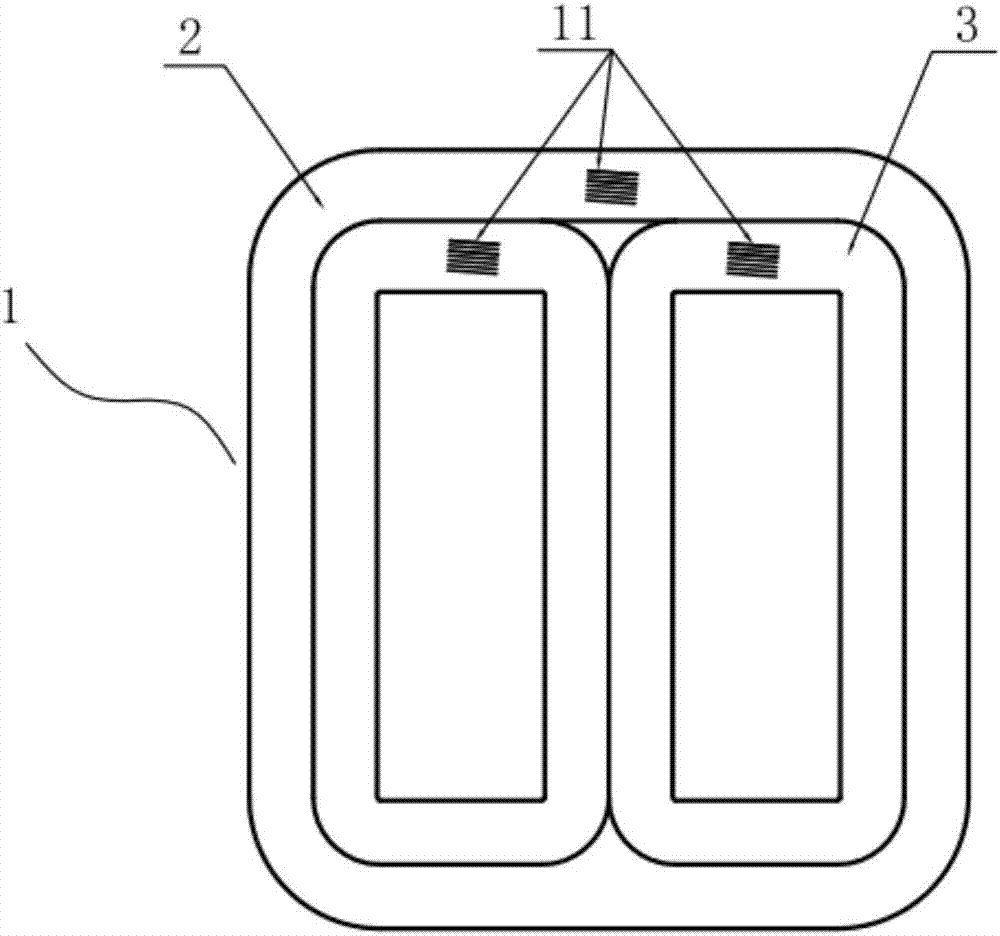

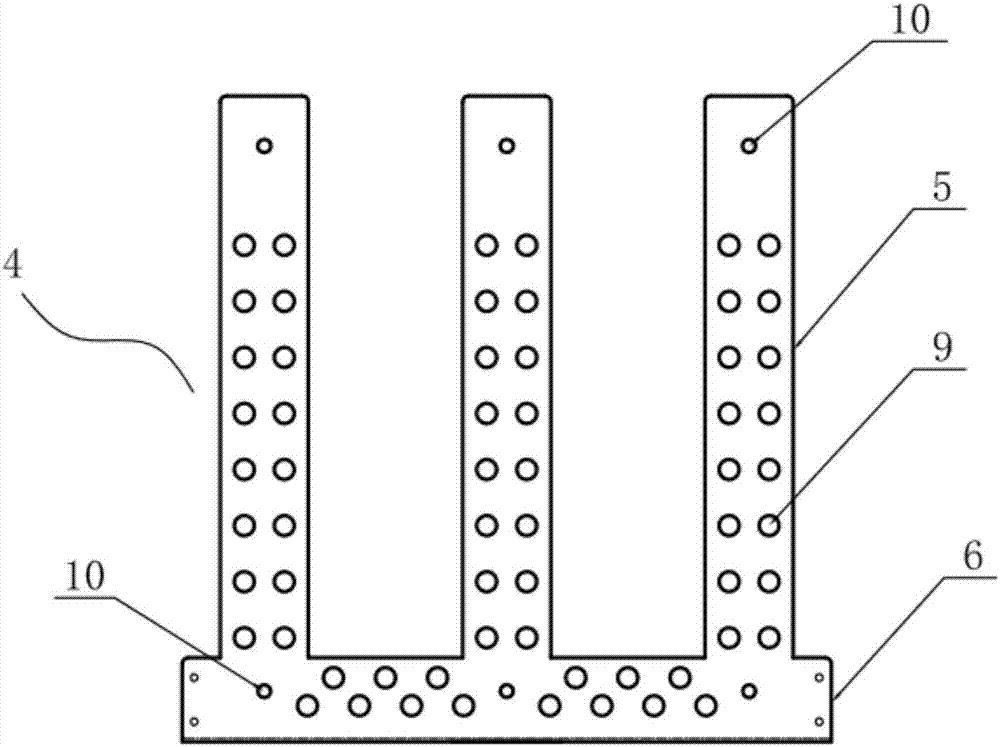

ActiveCN104565624AEliminate quality defectsImprove tensile and bending moment performancePipe-jointsEngineeringFlange

The invention relates to an integrated insulating joint. The joint comprises a left steel short pipe, a right steel short pipe, a left flange, a right flange, a joint sleeve, a first insulated sealing piece, a second insulated sealing piece, an insulated filling material and an insulated sealing ring, wherein an external thread is formed in the outer wall of the left steel short pipe; an internal thread is formed in the inner wall of the left flange; the external thread formed in the outer wall of the left steel short pipe and the internal thread formed in the inner wall of the left flange are matched to form a fixed connection mode; the threads through which the left steel short pipe and the left flange are in threaded connection are matched at the two starting ends so as to realize angle joint structure welding; an external thread is formed in the outer wall of the right steel short pipe; an internal thread is formed in the inner wall of the right flange; the external thread formed in the outer wall of the right steel short pipe and the internal thread formed in the inner wall of the right flange are matched to form a fixed connection mode; and the threads through which the right steel short pipe and the right flange are in threaded connection are matched at the two starting ends so as to realize angle joint structure welding. The yield of the finished product is high, the production cost can be greatly reduced, the production period is shortened, the joint is safe, and the standard specification is met.

Owner:CHENGDU SHANHAI HEAT SHRINKABLE PROD

Three-column amorphous iron core with pulling plate and manufacturing method thereof

ActiveCN107180695AAvoid damageReduce the amount of fragmentationTransformers/inductances magnetic coresInductances/transformers/magnets manufactureEpoxyLap joint

The invention discloses a three-column amorphous iron core with a pulling plate. The three-column amorphous iron core with the pulling plate comprises an amorphous iron core body and the pulling plate, wherein the amorphous iron core body comprises an outer frame iron core and two inner frame iron cores which are of an integral structure. The three-column amorphous iron core with the pulling plate also comprises a grid cloth plate and a composite membrane plate which are arranged between the amorphous iron core body and the pulling plate, wherein the grid cloth plate and the composite membrane plate keep away from a lap joint port of the amorphous iron core body, and the amorphous iron core body, the grid cloth plate, the composite membrane plate and the pulling plate are integrally cured through epoxy resin. The invention also discloses a manufacturing method of the three-column amorphous iron core with the pulling plate. According to the three-column amorphous iron core with the pulling plate, disclosed by the invention, the outer frame iron core and the inner frame iron cores are integrally formed before annealing, and then the fragment amount in a follow-up assembling process is reduced, so that the no-load loss and noise of a transformer are effectively reduced. By additionally arranging the grid cloth plate and the composite membrane plate, the insulation resistance value of the transformer can be effectively increased, and the stability of the transformer can be guaranteed.

Owner:FOSHAN CITY ZHONGYAN AMORPHOUS TECH

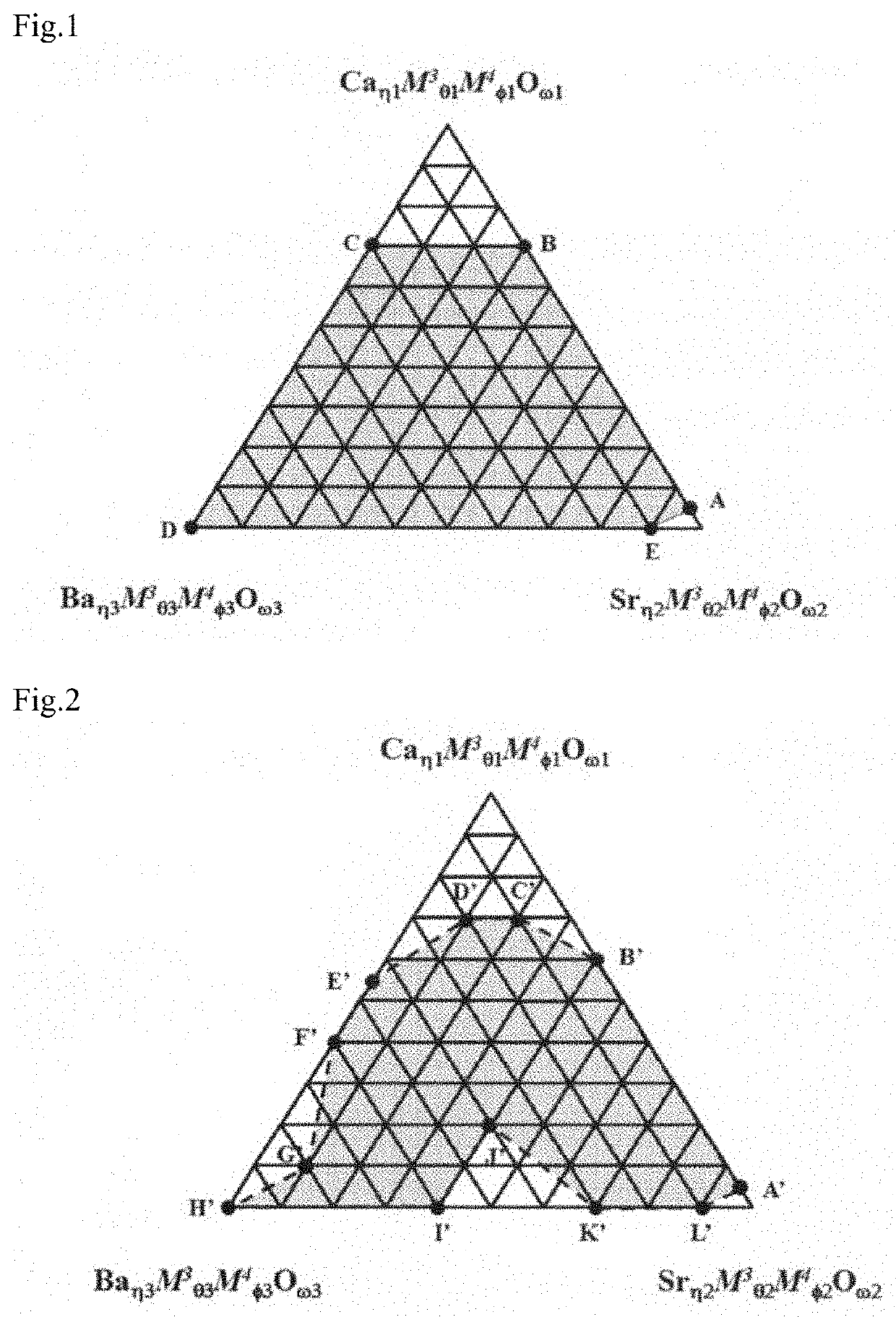

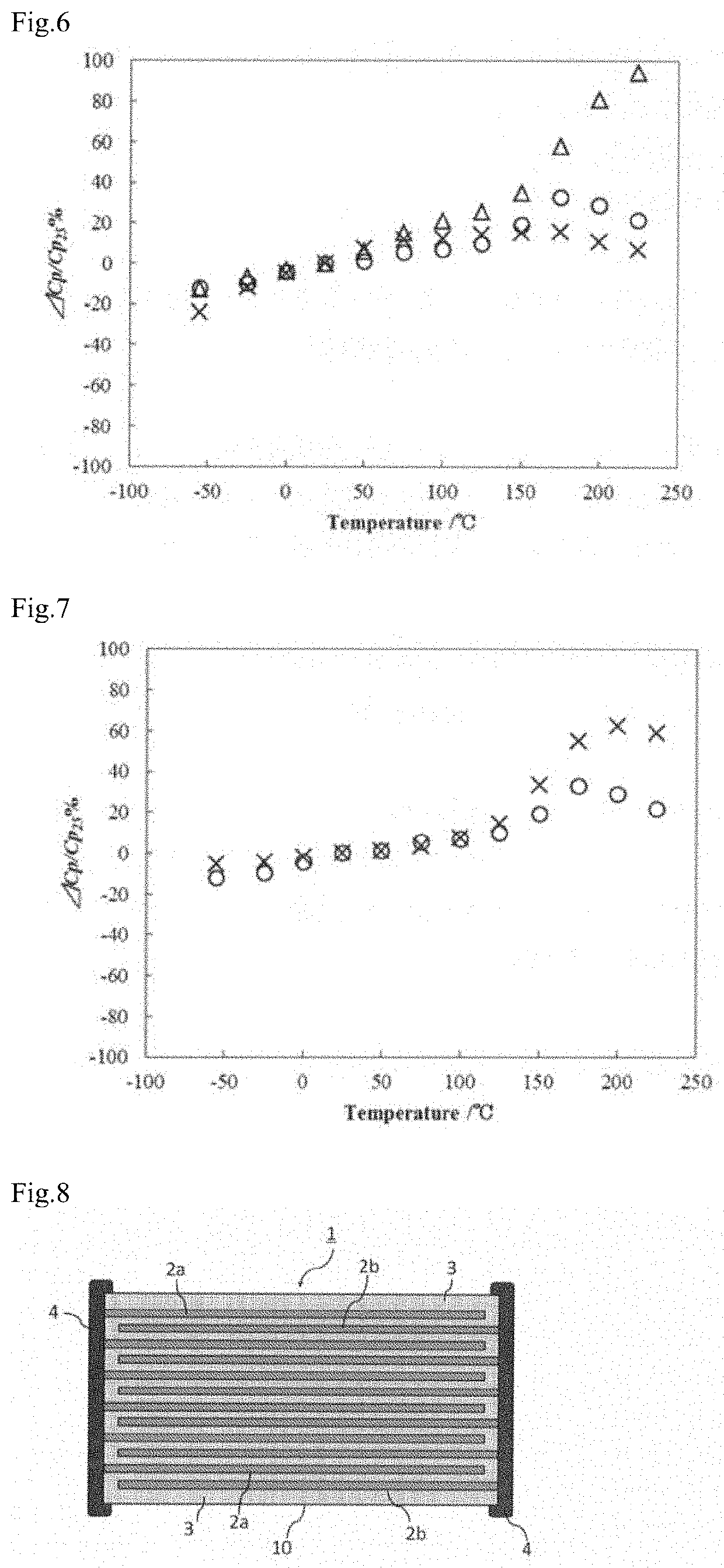

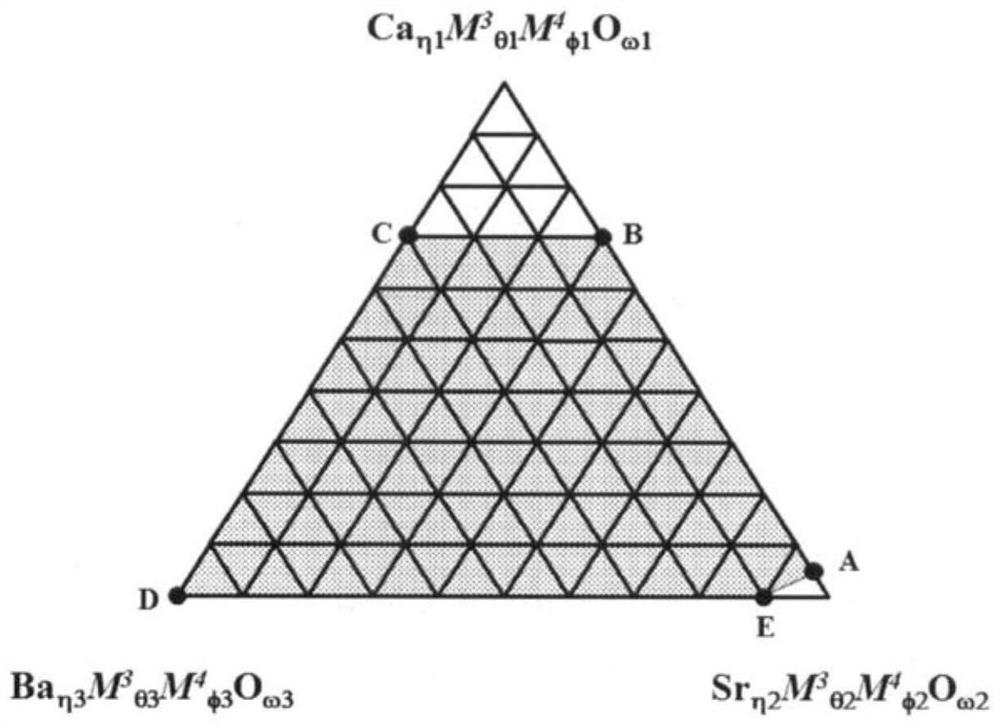

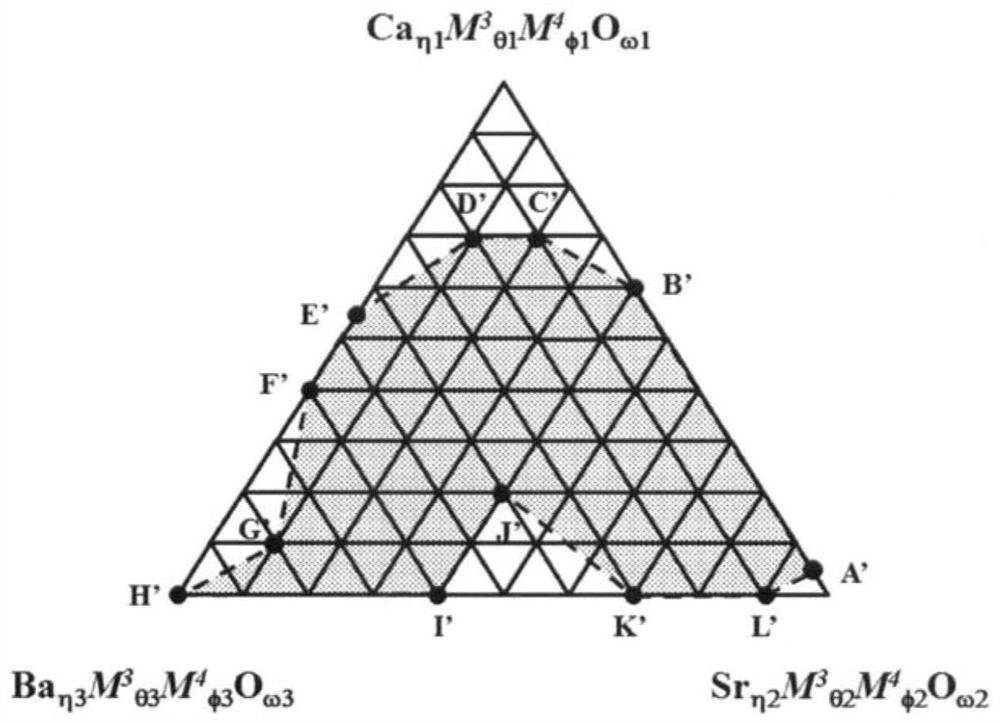

Dielectric ceramic composition and ceramic electronic component

ActiveUS20210155549A1High dielectric constantLittle changeFixed capacitor electrodesFixed capacitor dielectricPhysical chemistryDielectric ceramics

A dielectric ceramic composition including a first component and a second component. The first component comprises an oxide of Ca of 0.00 mol % to 35.85 mol % an oxide of Sr of 0.00 mol % to 47.12 mol %, an oxide of Ba of 0.00 mol % to 51.22 mol %, an oxide of Ti of 0.00 mol % to 17.36 mol %, an oxide of Zr of 0.00 mol % to 17.36 mol %, an oxide of Sn of 0.00 mol % to 2.60 mol %, an oxide of Nb of 0.00 mol % to 35.32 mol %, an oxide of Ta of 0.00 mol % to 35.32 mol %, and an oxide of V of 0.00 mol % to 2.65 mol %. The second component includes (by mass) at least (a) an oxide of Mn of 0.005% to 3.500% by mass and (b) one or both of an oxide of Cu of 0.080% by mass to 20.000% and an oxide of Ru of 0.300% to 45.000%.

Owner:SHOEI CHEM IND CO LTD

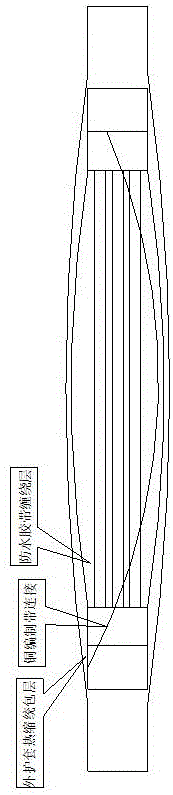

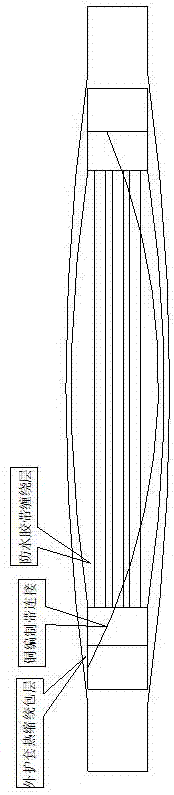

Submersible motor winding and power supply connecting structure

InactiveCN106300757ARegular shapeImprove the insulation resistance valueWindingsPower cableElectric machine

The invention provides a submersible motor winding and power supply connecting structure, which comprises a motor winding wire connector and a power cable lead-out wire connector, wherein the motor winding wire connector and the power cable lead-out wire connector are in parallel lapping joint in a manner of facing each other and are sleeved with a metal pipe, the metal pipe fastens the two connectors in a cold pressure welding manner, is coated with a layer of clay, the periphery of the clay is level with the outer surface of an motor winding wire outer sheath, outer diameters of the motor winding wire outer sheath and a power cable lead-out wire outer sheath are identical, and the clay is coated with a heat-shrinkable casing pipe. By adopting the structure, the two connected connectors have no burr and are regular in shape when compared with two connectors connected by adopting a tin soldering method in the prior art, the metal pipe is coated with the layer of clay and sleeved with the heat-shrinkable casing pipe, and the residual air in the inside is extruded out, thereby eliminating the hidden dangers of discharge; and by adopting the improved connectors, an insulation resistance value and a breakdown voltage value are greatly improved, the submersible motor winding and power supply connecting structure is stable in performance when immersed in water for a long time, and the service life of the product is prolonged.

Owner:TIANJIN YUANQUAN ELECTROMECHANICAL EQUIP MFG

Soldering paste

InactiveCN109514125AImprove self-leveling propertiesReduce the frequency of scraping solder pasteWelding/cutting media/materialsSoldering mediaActive agentPolyamide

The invention relates to the technical field of paste welding materials, in particular to soldering paste. The soldering paste comprises scaling powder and tin-based alloy powder. The scaling powder comprises following raw materials including, by weight percent, 2%-15% of a thixotropic agent, 0%-13% of an active agent, 17%-22% of polymerized rosin, 0%-12% of hydrogenated rosin and the balance organic solvent. The thixotropic agent comprises following raw materials including, by weight percent, 0%-5% of EBS, 0%-4% of high-performance amide wax micro powder, 0%-3% of polyamide modified hydrogenated castor oil ramification and the balance butyl carbitol- terpilenol mixture. The active agent comprises following raw materials including, by weight percent, 1%-6% of decyltetradecanoicacid, 0.5%-5% of a fluorinated surfactant, 1%-5% of 2-ethyl imidazole and the balance butyl carbitol-terpilenol mixture. According to the soldering paste, the self-leveling character of the solder paste body is improved, and multi-time solder paste adhering amount consistency is improved; and wettability during welding is improved, and meanwhile the residual insulation resistance value after welding is improved as well.

Owner:深圳市唯特偶新材料股份有限公司

Dielectric ceramic composition and ceramic electronic component

ActiveCN111954649ALittle changeImprove the insulation resistance valueFixed capacitor electrodesStacked capacitorsElectric capacityDielectric loss

A dielectric ceramic composition comprises a first ingredient and a second ingredient. The first ingredient comprises 0.00 to 35.85% by mole of an oxide of Ca, 0.00 to 47.12% by mole of an oxide of Sr, 0.00 to 51.22% by mole of an oxide of Ba, 0.00 to 17.36% by mole of an oxide of Ti, 0.00 to 17.36% by mole of an oxide of Zr, 0.00 to 2.60% by mole of an oxide of Sn, 0.00 to 35.32% by mole of an oxide of Nb, 0.00 to 35.32% by mole of an oxide of Ta, and 0.00 to 2.65% by mole of an oxide of V. As the second ingredient, the dielectric ceramic composition comprises at least 0.005 to 3.500% by massof an oxide of Mn (a); and 0.080 to 20.000% by mass of an oxide of Cu and / or 0.300 to 45.000% by mass of an oxide of Ru (b). According to the present invention, the dielectric ceramic composition canbe provided, wherein changes in the electrostatic capacity are small even under a high-temperature environment, dielectric losses at 25 DEG C and 200 DEG C are small, and the insulation resistance value under a high-temperature environment is high.

Owner:SHOEI CHEM IND CO LTD

A kind of docking method of 10kv XLPE cable

InactiveCN106848990BWaterproofImprove moisture resistanceSoldered/welded conductive connectionsConnections effected by permanent deformationInsulation layerButt joint

The invention relates to a docking method of a 10 kV crosslinked polyethylene cable. The docking method comprises the specific steps of firstly aligning two sections of cables which need to be in butt joint, stripping cable outer protective sleeves, steel armor layers and inner protective layers in sequence from all ports, and taking down cable filling materials; sleeving one end of the cable with a radioactive heat shrink tube for use after cable butt joint manufacturing is completed; then stripping copper shielding layers and semi-conductive layers in sequence from all the ports; measuring the length of a copper pressed connecting tube which is connected with the cable cores, adopting 1 / 2 of the length of the cable core and adding 5 mm on the length, which is a basis that main insulation parts of the cables which needs to be stripped are exposed out of the conductive cores, according to the length, stripping cable main insulation layers from the ports, cutting the main insulation fractures into pencil tip shapes with the length of 60 mm, and making an inner semi-conductive layers with the length of 5mm exposed; connecting the conductive cores; finally using the sleeved outer protective sleeve radioactive heat shrinkage tube to conduct uniform covering and heat shrinkage on the outer protective sleeve at the middle joint. Compared with a traditional method, the docking method of the 10 kV crosslinked polyethylene cable has superior moisture resistance, waterproofness and insulating properties.

Owner:刘国晓

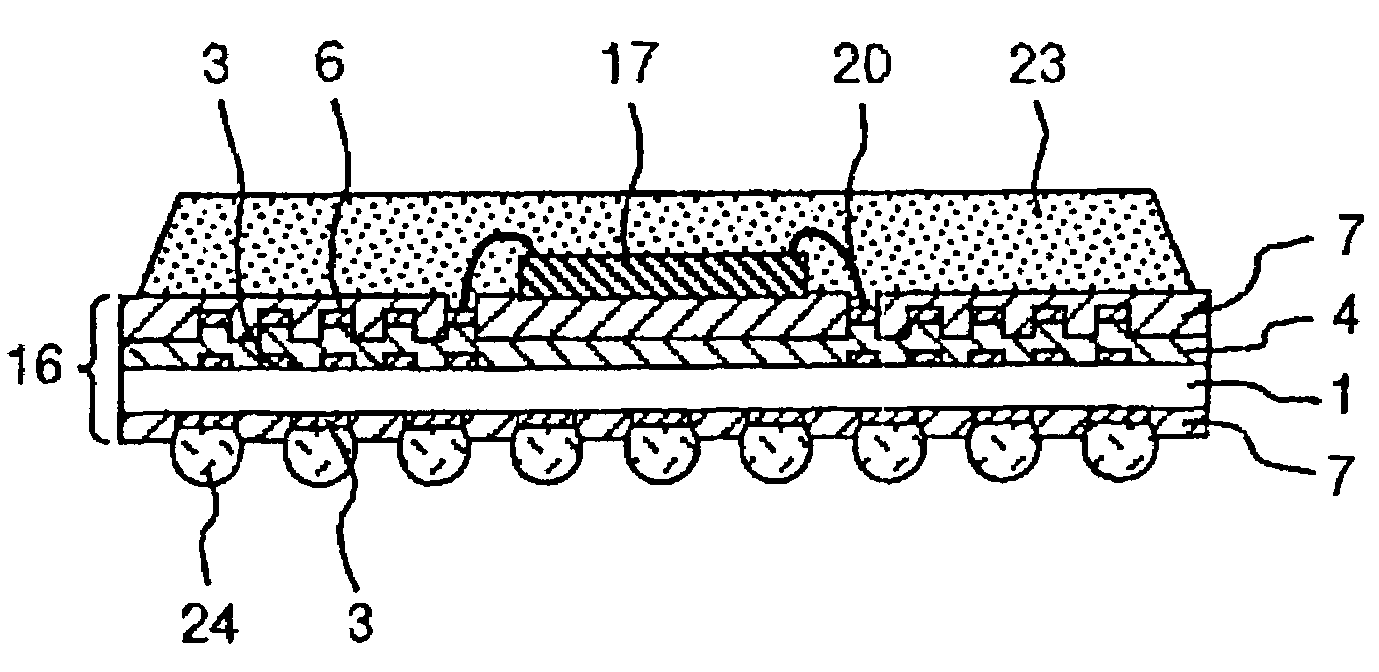

Printed wiring board and electronic device using the same

InactiveUS7355127B2Improve the insulation resistance valueSemiconductor/solid-state device detailsPrinted electric component incorporationElectrical conductorEngineering

The present invention provides a printed wiring board which has high insulation resistance between wirings and is unlikely to cause failures such as leakages or short circuits, attributable to ion migration even in high temperatures and highly humid environments. The printed wiring board has a circuit comprising a metal conductor on base metal layers created by forming an insulating resin layer 4 on at least one face of an insulating substrate 1 and forming the base metal layers 2 and 5 on the insulating resin layer. In the printed wiring board, at least a part of an upper face of the insulating resin layer existing in spaces 11 between the metal conductors is formed at a position lower than the interface between the base metal layer 5 and the insulating resin layer 4.

Owner:RENESAS ELECTRONICS CORP

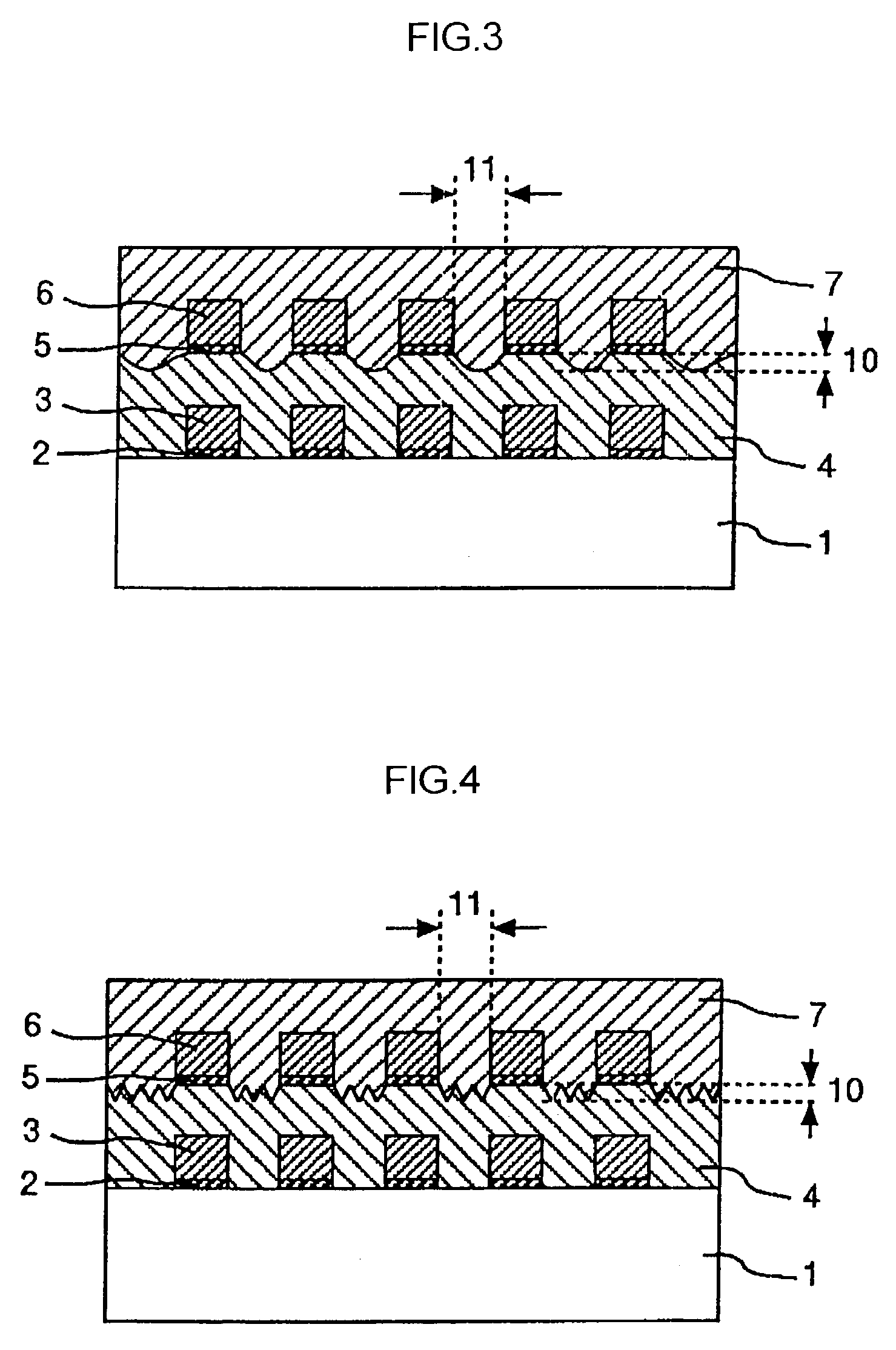

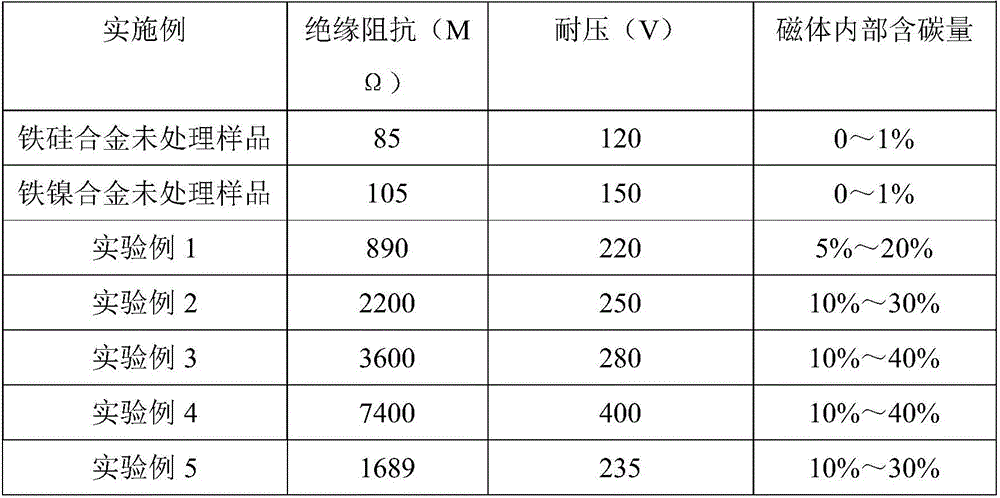

A kind of iron-based powder core magnet and its manufacturing method

ActiveCN106086770BImprove the insulation resistance valueIncreased DC withstand voltageSolid state diffusion coatingMagnetic materialsCarbon potentialRoom temperature

The invention discloses an iron-based powder core magnet and a manufacturing method thereof. The manufacturing method includes the following steps of S1, placing the iron-based powder core magnet in an organic carbon source steam atmosphere, processing the iron-based powder core magnet for 1 hour to 5 hours under the conditions that the temperature T1 is higher than 100 DEG C but lower than or equal to 500 DEG C, the intensity of pressure is 1-20 MPa and the carbon potential is controlled to be 0.4-2.0%, and making the surface of the iron-based powder core magnet adsorb active carbon atoms; taking out the iron-based powder core magnet after waiting for the iron-based powder core magnet to be cooled to room temperature, then placing the iron-based powder core magnet in an inert gas atmosphere, processing the iron-based powder core magnet for 1 hour to 6 hours under the condition that the temperature T2 is higher than 500 DEG C but lower than or equal to 900 DEG C, and making the adsorbed active carbon atoms on the surface permeate into the iron-based powder core magnet; S2, immersing the iron-based powder core magnet into fast quenching oil and completing quenching under the condition of 70+ / -10 DEG C; and S3, rinsing the iron-based powder core magnet, and then performing drying treatment operation. The obtained iron-based powder core magnet has higher insulation and pressure-tolerant characteristics and the manufacturing method can realize mass production.

Owner:SHENZHEN SUNLORD ELECTRONICS

Integral Insulated Joint

The invention relates to an integrated insulating joint. The joint comprises a left steel short pipe, a right steel short pipe, a left flange, a right flange, a joint sleeve, a first insulated sealing piece, a second insulated sealing piece, an insulated filling material and an insulated sealing ring, wherein an external thread is formed in the outer wall of the left steel short pipe; an internal thread is formed in the inner wall of the left flange; the external thread formed in the outer wall of the left steel short pipe and the internal thread formed in the inner wall of the left flange are matched to form a fixed connection mode; the threads through which the left steel short pipe and the left flange are in threaded connection are matched at the two starting ends so as to realize angle joint structure welding; an external thread is formed in the outer wall of the right steel short pipe; an internal thread is formed in the inner wall of the right flange; the external thread formed in the outer wall of the right steel short pipe and the internal thread formed in the inner wall of the right flange are matched to form a fixed connection mode; and the threads through which the right steel short pipe and the right flange are in threaded connection are matched at the two starting ends so as to realize angle joint structure welding. The yield of the finished product is high, the production cost can be greatly reduced, the production period is shortened, the joint is safe, and the standard specification is met.

Owner:CHENGDU SHANHAI HEAT SHRINKABLE PROD

High temperature solder paste for semiconductor

ActiveCN108544140BImprove self-leveling propertiesReduce the frequency of scraping solder pasteWelding/cutting media/materialsSoldering mediaActive agentPolyamide

High-temperature solder paste for semiconductors, including flux and tin-based alloy powder, the flux includes the following raw materials: thixotropic agent, active agent, polymerized rosin, hydrogenated rosin, and the balance is an organic solvent; the thixotropic agent includes the following raw materials : ethylene bis stearamide, high-performance amide wax micropowder, polyamide modified hydrogenated castor oil derivatives, and the balance is the mixture of butyl carbitol-terpineol; the active agent includes the following raw materials: decyl Myristic acid, fluorosurfactant, 2‑ethylimidazole, the balance is a mixture of butyl carbitol‑terpineol. In the present invention, by adjusting the components in the thixotropic agent, the self-leveling properties of the solder paste body are improved, the frequency of scraping the solder paste by the operator is reduced, the consistency of the amount of solder paste is improved for multiple times, and the moisturization during soldering is improved. Moisture also improves the residual insulation resistance value after welding, thereby improving the electrical performance of customers' products.

Owner:东莞市仁信电子有限公司

Iron-based powder core magnet and manufacturing method thereof

ActiveCN106086770AImprove the insulation resistance valueIncreased DC withstand voltageSolid state diffusion coatingMagnetic materialsCarbon potentialRoom temperature

The invention discloses an iron-based powder core magnet and a manufacturing method thereof. The manufacturing method includes the following steps of S1, placing the iron-based powder core magnet in an organic carbon source steam atmosphere, processing the iron-based powder core magnet for 1 hour to 5 hours under the conditions that the temperature T1 is higher than 100 DEG C but lower than or equal to 500 DEG C, the intensity of pressure is 1-20 MPa and the carbon potential is controlled to be 0.4-2.0%, and making the surface of the iron-based powder core magnet adsorb active carbon atoms; taking out the iron-based powder core magnet after waiting for the iron-based powder core magnet to be cooled to room temperature, then placing the iron-based powder core magnet in an inert gas atmosphere, processing the iron-based powder core magnet for 1 hour to 6 hours under the condition that the temperature T2 is higher than 500 DEG C but lower than or equal to 900 DEG C, and making the adsorbed active carbon atoms on the surface permeate into the iron-based powder core magnet; S2, immersing the iron-based powder core magnet into fast quenching oil and completing quenching under the condition of 70+ / -10 DEG C; and S3, rinsing the iron-based powder core magnet, and then performing drying treatment operation. The obtained iron-based powder core magnet has higher insulation and pressure-tolerant characteristics and the manufacturing method can realize mass production.

Owner:SHENZHEN SUNLORD ELECTRONICS

Anti-sputtering Faraday cup and preparation method thereof

PendingCN114779311AImprove the insulation resistance valueHigh measurement accuracyX/gamma/cosmic radiation measurmentMetal-working hand toolsMaterials scienceComposite material

The invention relates to an anti-sputtering Faraday cylinder which comprises a bias electrode, a collecting electrode, a diaphragm and a shielding cylinder. The bias electrode is in the shape of a cylinder with two open ends, and a first flange extending outwards is formed at the top of the bias electrode. The collecting electrode is in a cylindrical shape, the top end of the collecting electrode is open, the bottom end of the collecting electrode is closed, the diaphragm is in a cylindrical shape, the diaphragm is arranged on the outer side of the bias electrode in a sleeving mode, and the bias electrode is fixed to the inner wall of the diaphragm through the first flange. The bottom end of the shielding cylinder is closed, the shielding cylinder is arranged on the outer side of the collecting electrode in a sleeving mode, the collecting electrode is fixed to the inner wall of the shielding cylinder through the second electrode, and the bottom of the shielding cylinder is separated from the bottom end of the collecting electrode. The bias electrode and the collecting electrode as well as the bias electrode and the ground are insulated through vacuum, and only a small part of ceramic is far away from a beam and a sputtering beam path, so that the problem of ceramic pollution can be effectively solved.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

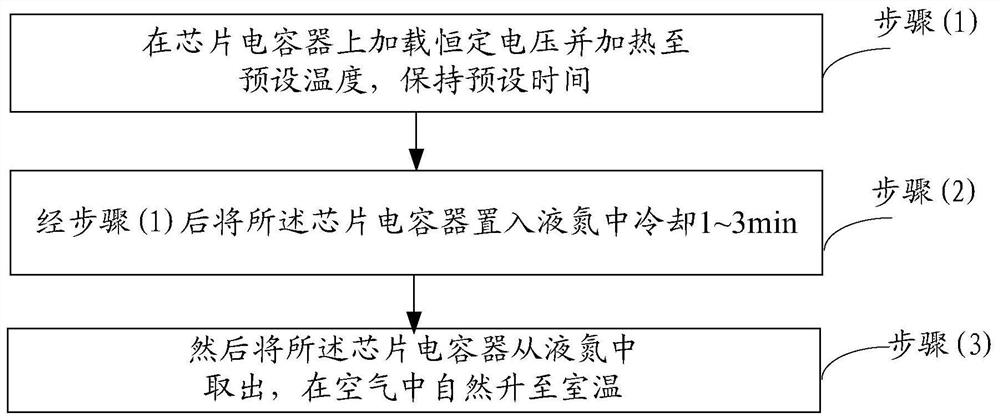

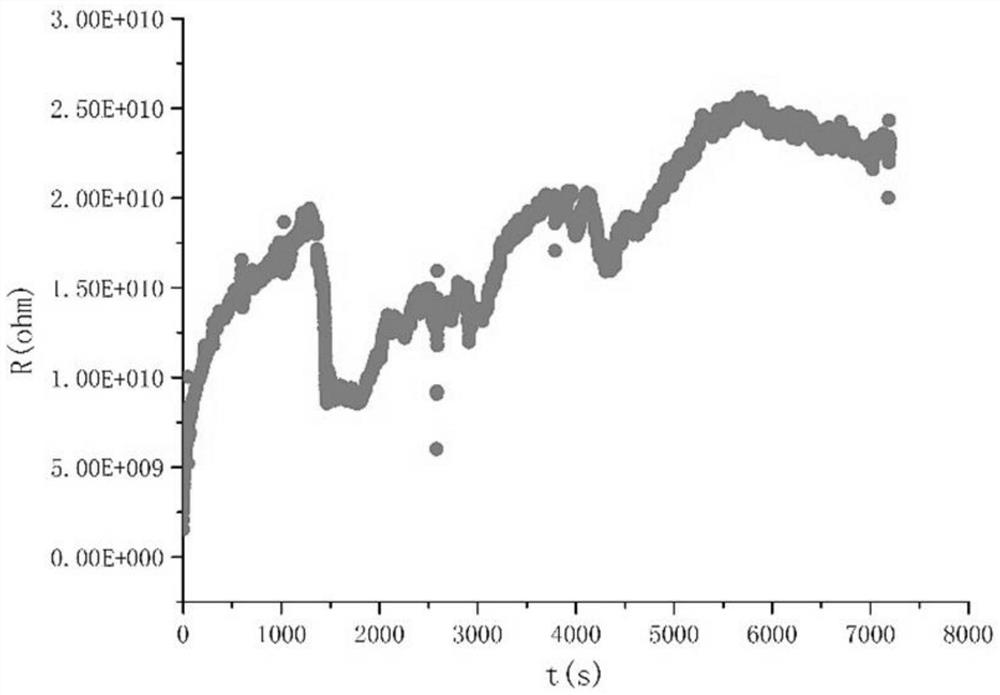

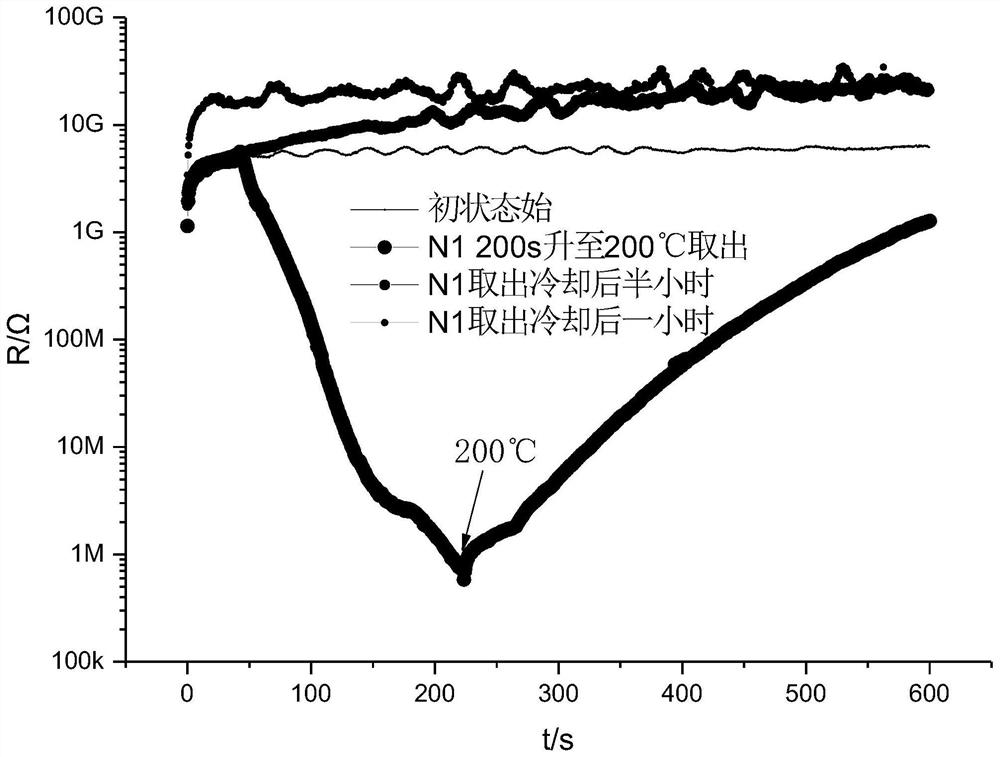

A method of improving the insulation resistance value of chip capacitor

InactiveCN110189929BImprove the insulation resistance valueImprove insulation performanceCapacitor manufactureCapacitancePhysical chemistry

The invention discloses a method for improving the insulation resistance value of a chip capacitor, which includes: loading a constant voltage on the chip capacitor; heating up to a preset temperature in an annealing furnace and keeping it for a preset time; placing the chip capacitor in liquid nitrogen Cool for 1-3 minutes; then take out the chip capacitor and let it rise to room temperature naturally in the air. This method utilizes the characteristic that the insulation resistance value of the STO chip capacitor increases continuously with the load voltage and time, and performs rapid heat treatment on the chip capacitor under the condition of the loaded voltage. This method is simple and easy to implement. Without changing the capacitance value, loss and capacitance temperature coefficient of the capacitor, the insulation resistance value and consistency of the STO ceramic chip are greatly improved. After removing the applied voltage and thermal conditions, the STO chip capacitor is insulated The resistance value does not decay over time.

Owner:HUBEI UNIV +1

Ferrite substrate, thin-film common mode filter using the substrate, thin-film common mode filter array using the substrate and manufacturing method of the substrate

ActiveUS7387847B2High surface insulation resistanceLess surface-degradationInorganic material magnetismFerroso-ferric oxidesFerrite substrateOptoelectronics

A ferrite substrate for thin-film inductors is provided by means of blending raw materials to meet a composition of di-iron trioxide (Fe2O3): 40 to 55 mol %, nickel oxide (NiO): 5 to 35 mol %, zinc oxide (ZnO): 10 to 40 mol %, and bismuth trioxide (Bi2O3): 150 to 750 ppm, or of Fe2O3: 40 to 55 mol %, NiO: 5 to 35 mol %, ZnO: 10 to 40 mol %, cupric oxide (CuO): 5 to 10 mol %, and manganese dioxide (MnO2): 0.5 to 2 mol %, and then molding and sintering the blended material, and applying hot isostatic pressing to the sintered article. A thin-film common mode filter and a thin-film common mode filter array using the ferrite substrate and the manufacturing method of the substrate are also provided.

Owner:TDK CORPARATION

A Method for Improving the Insulation Performance of Large-scale Motors on Site

ActiveCN108539938BImprove insulation performanceHigh insulation resistanceManufacturing dynamo-electric machinesThermodynamicsElectric machine

The present invention relates to a method for improving the insulation performance of a large-scale motor on site, comprising: S010, a current drying step, starting a drying power supply, applying a current to the winding inside the motor from the drying power supply, and the time for continuously applying the current is A hours; S020, Pass hot air through the upper tuyere of the motor, and discharge the hot air through the winding inside the motor from the lower tuyere; S030, pass hot air through the lower tuyere of the motor, and discharge the hot air through the winding inside the motor from the upper tuyere. In the present invention, under the condition that the motor is not disassembled, the electric current heating step and the hot air drying step are performed on the inner winding of the motor to realize drying inside the motor, thereby improving the insulation performance of the motor.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

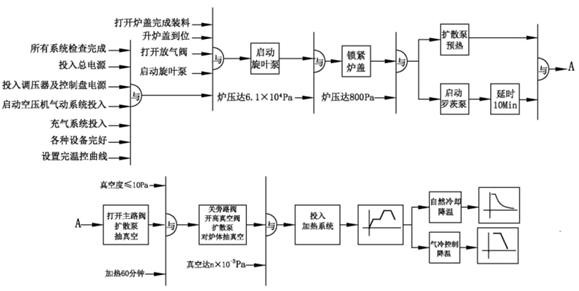

High-vacuum annealing process of armored thermocouple and armored wire

PendingCN112331415AGuaranteed armor strengthHigh physical and chemical stabilityThermometers using electric/magnetic elementsApparatus for heat treatmentInsulation resistanceDiffusion pump

The invention discloses a high-vacuum annealing process of an armored thermocouple and an armored wire. The high-vacuum annealing process comprises the following steps: A, preparing a system and equipment; B, completing PLD programming (system preparation and system condition completion), closing a main power supply, charging, ascending a furnace cover in place, starting a circulating water system, starting a control gas source and pneumatic valve system, starting an instrument and control system, starting a vacuum system, starting a rotary vane pump and starting a roots pump; C, when the conditions are met, starting a diffusion pump, when the vacuum degree is reached, putting into a heating system, keeping constant temperature for a period of time according to a heating curve, and finallycooling; and D, when the temperature reaches 50 DEG C, shutting down the furnace for material taking, and shutting down all the systems. The armored thermocouple and the armored wire which are subjected to high-vacuum annealing are bright in surface and free of pits under a microscope, the withstand voltage between wires and the withstand voltage of a wire pair armor body can generally reach 2000V or above, the insulation resistance can generally reach 20 G and can reach 100 G or above to the maximum, the armored thermocouple and the armored wire are bent, and the armor body does not crack.

Owner:沈阳宇光温度仪表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com