High-vacuum annealing process of armored thermocouple and armored wire

A technology of armored thermocouples and annealing process, which is applied in the direction of thermometers, cable/conductor manufacturing, circuits, etc., which are directly sensitive to heat, electric/magnetic elements, etc., to achieve high insulation resistance, high physical and chemical stability, and high dielectric intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

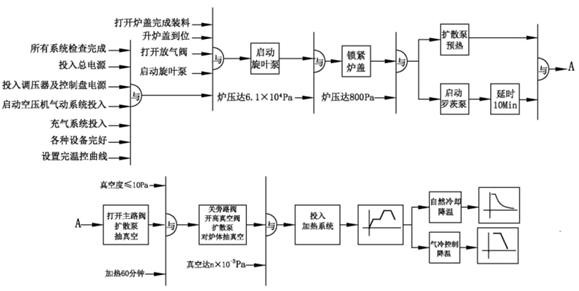

[0041] Step 1: Set the PID temperature regulator and PLD programming according to the requirements of the annealing material, and complete the high vacuum annealing furnace body, vacuum system, cooling water system, electrical system, pumping, exhaust and inflation system , electronic control and instrumentation systems are prepared;

[0042] Step 2: Complete all system inspections, put in the main power supply, put in the voltage regulator and control panel power supply, put in the pneumatic system of the start-up air compressor, put in the gas charging system, and keep all kinds of equipment in good condition; open the furnace cover to complete the charging, and lift the furnace cover in place 1. Open the vent valve and start the rotary vane pump. When the furnace pressure reaches 800pa, preheat the diffusion pump and turn on the Roots pump at the same time. After heating for 60 minutes, open the main valve and the diffusion pump for vacuuming;

[0043] Step 3: When the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com