Distributing base board and electronic device using it

A technology of wiring substrates and insulating substrates, which is applied to circuits, printed circuits, electrical components, etc., and can solve problems such as current leakage and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

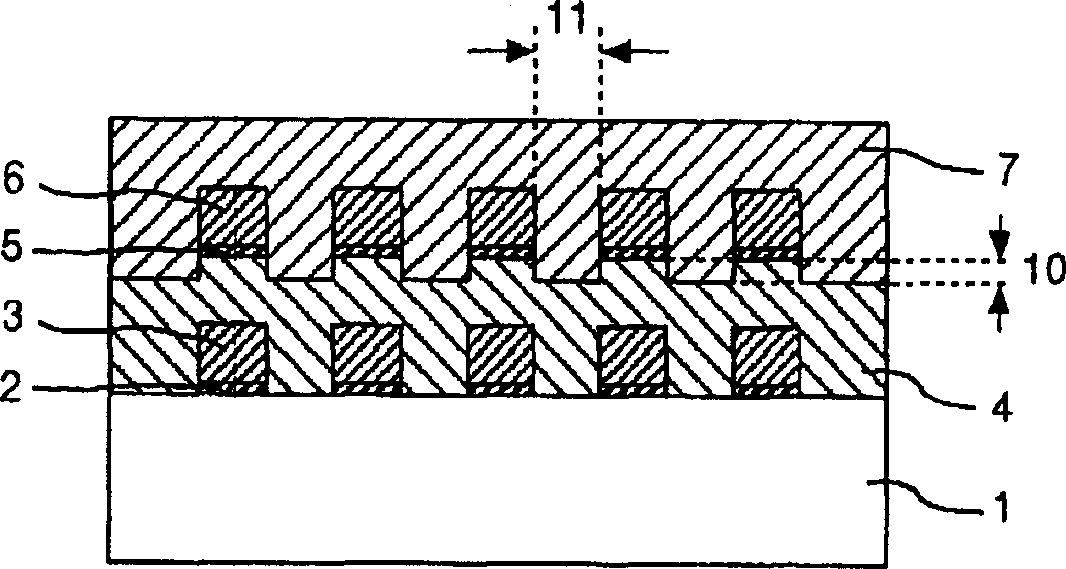

[0066] figure 1 is a schematic cross-sectional view of the wiring board of this embodiment. The upper part of the insulating resin layer 4 located on the metal conductor (wiring) space 11 is formed lower than the surface connecting the lower surface of the base layer 5 and the upper surface of the insulating layer 4, and the protective insulating layer 7 is formed thereon.

[0067] That is, the interface between the insulating resin layer 4 and the protective insulating layer 7 on the metal conductor (wiring) space 11 is located at a position lower than the surface where the base metal layer 5 and the insulating resin layer 4 are connected by a height difference of 10.

[0068] Figure 13 The purpose is to form the upper part of the insulating resin layer 4 located between the metal conductors 11 lower than the surface where the base metal layer 5 and the insulating resin layer 4 are connected. Figure 12 An additional step diagram added after step (k) of the conventional m...

Embodiment 2

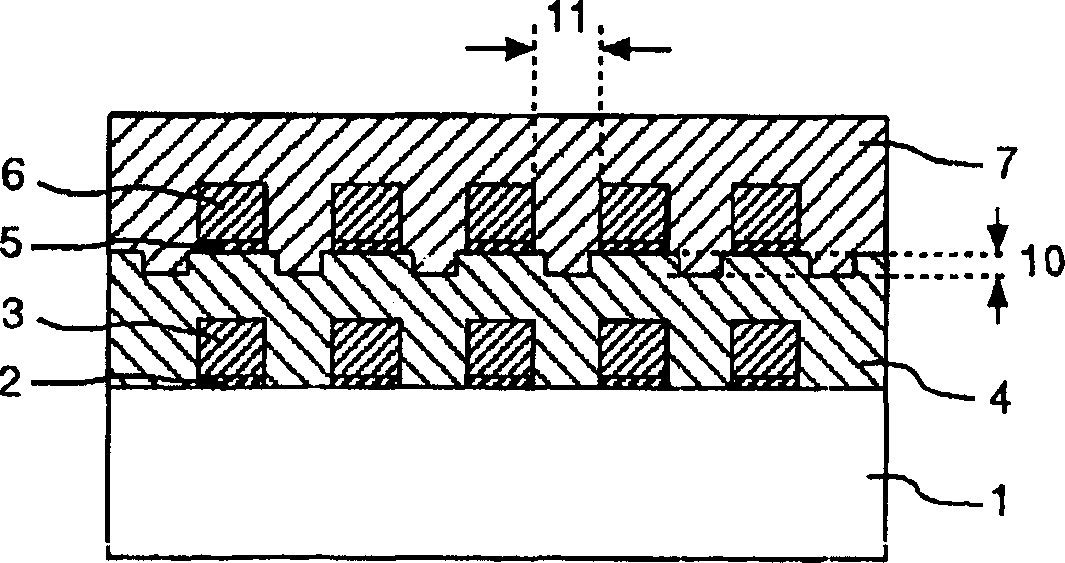

[0073] figure 2 is a schematic cross-sectional view of the wiring board of this embodiment. The central portion of the insulating resin layer 4 located between the metal conductors 11 is removed by ion beam processing to form a protective insulating layer 7 lower than the connection surface between the base metal layer 5 and the insulating resin layer 4 .

[0074] Part of the interface between the insulating resin layer 4 and the protective insulating layer 7 located on the metal conductor (wiring) space 11 is located at a position lower than the surface where the base metal layer 5 and the insulating resin layer 4 are connected by a height difference of 10. Also, the height of the step 10 is about 500 nm.

Embodiment 3

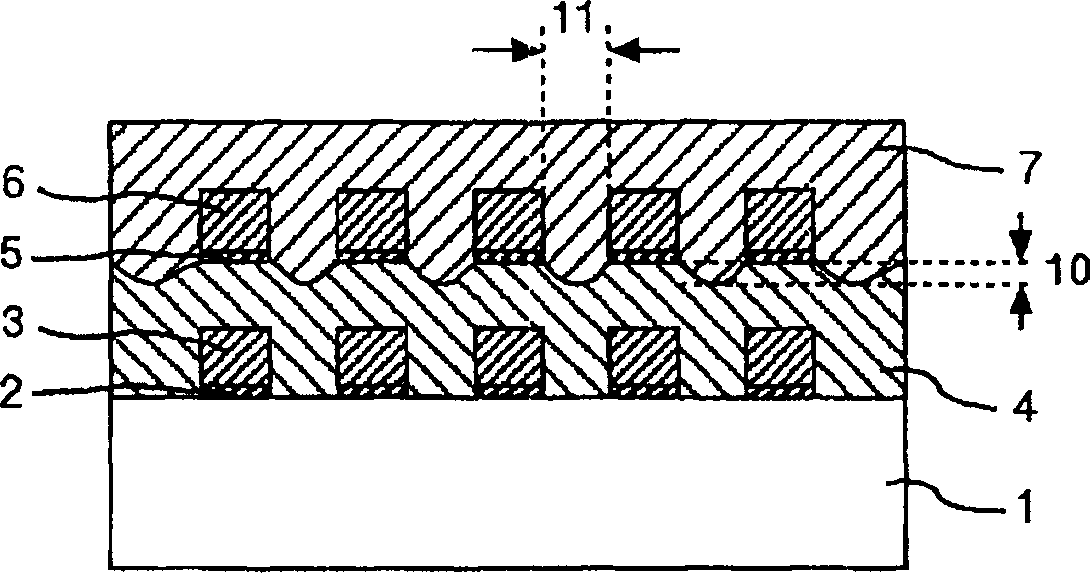

[0076] image 3 is a schematic cross-sectional view of the wiring board of this embodiment. The upper surface of the central portion of the insulating resin layer 4 located on the metal-conductor space 11 is removed by laser processing to form a concave shape. The bottom of this concave portion is formed lower than the surface where base metal layer 5 and insulating resin layer 4 are connected, and protective insulating layer 7 is formed thereon.

[0077] The recessed interface between the insulating resin layer 4 and the protective insulating layer 7 located on the metal conductor (wiring) space 11 is located only 10 steps lower than the surface where the base metal layer 5 and the insulating resin layer 4 are connected. Also, the height of the step 10 is about 1 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com