Anti-sputtering Faraday cup and preparation method thereof

A Faraday cage and anti-sputtering technology, which is applied in manufacturing tools, radiation measurement, X/γ/cosmic radiation measurement, etc., can solve pollution and other problems, and achieve accurate measurement, accurate beam adjustment equipment, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

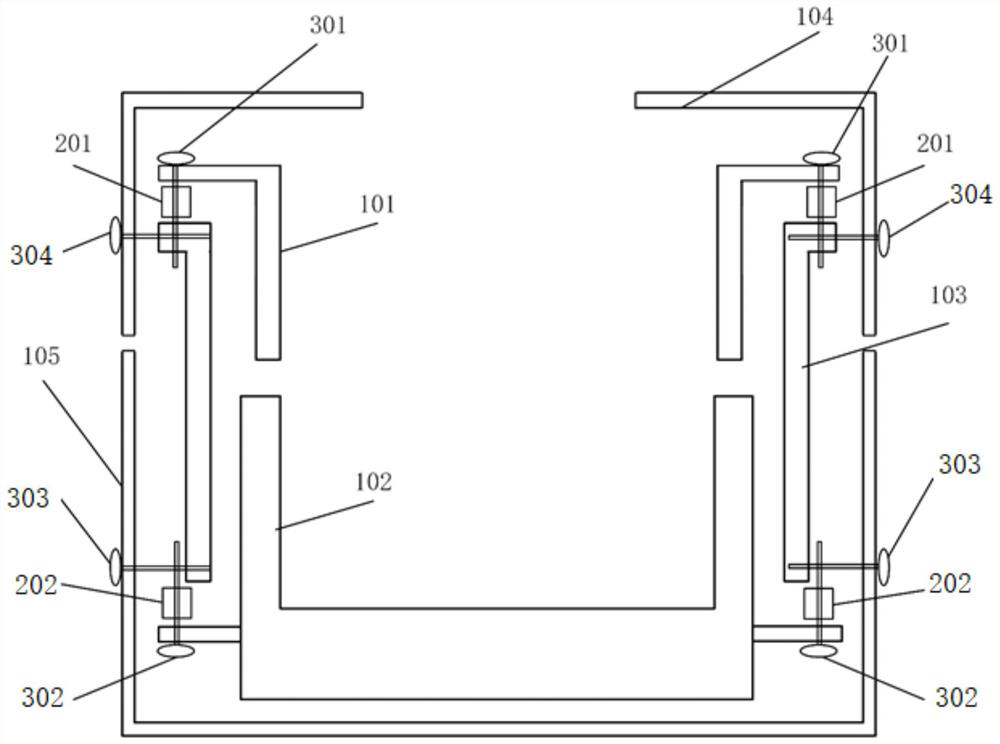

[0035] like figure 1 The anti-sputtering Faraday cylinder provided by the first embodiment of the present invention includes a bias electrode 101, a collector electrode 102, a diaphragm 104 and a shielding cylinder 105. The action of secondary electrons finally makes the current intensity measurement more accurate; the collecting electrode 102 is used to block and collect all the incident beam currents, and export the charge to the data acquisition device; the diaphragm 104 is used to protect the bias electrode 101, preventing the beam from bombarding the bias electrode 101 directly; the shielding cylinder 105 is used to isolate the external complex electromagnetic environment to ensure accurate measurement values and low noise. The bias electrode 101 includes a cylindrical shape with both ends open and a first flange extending outward from the top. A first threaded hole is respectively provided on the front, rear, left and right sides of the first flange. The bias electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com