A method of improving the insulation resistance value of chip capacitor

A technology of insulation resistance and capacitors, which is applied in the direction of capacitors, capacitor manufacturing, circuits, etc., can solve the problems of large differences in insulation resistance values of capacitors, poor consistency, and difficult technical control, so as to improve the insulation resistance value and improve the insulation resistance. Value and consistency, the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

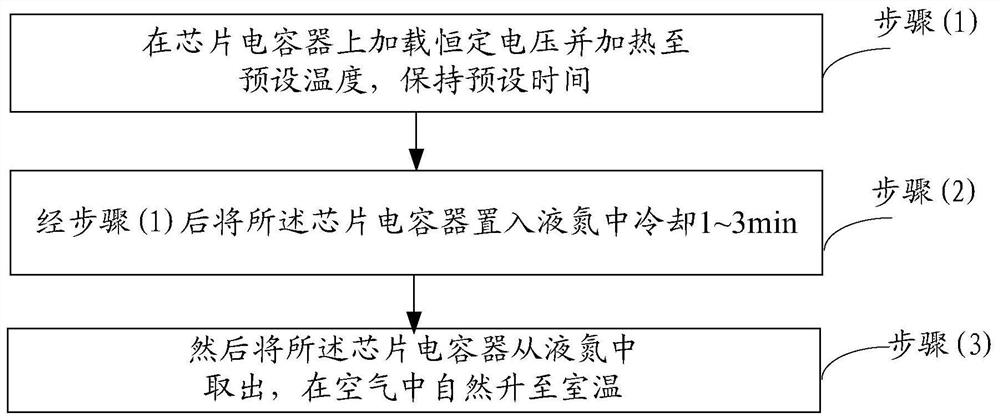

Method used

Image

Examples

Embodiment 1

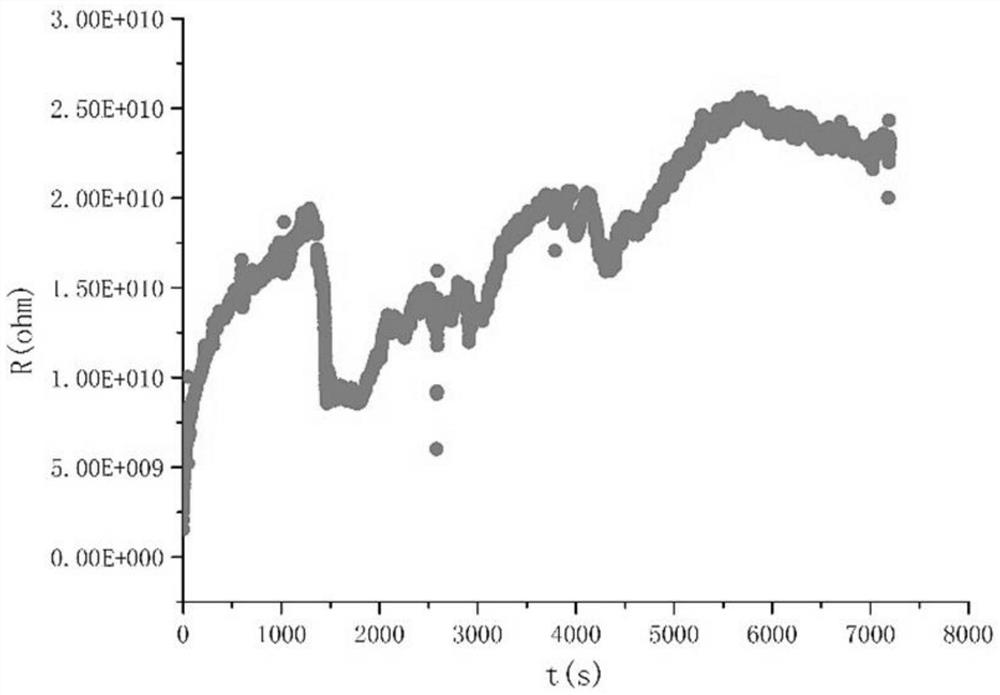

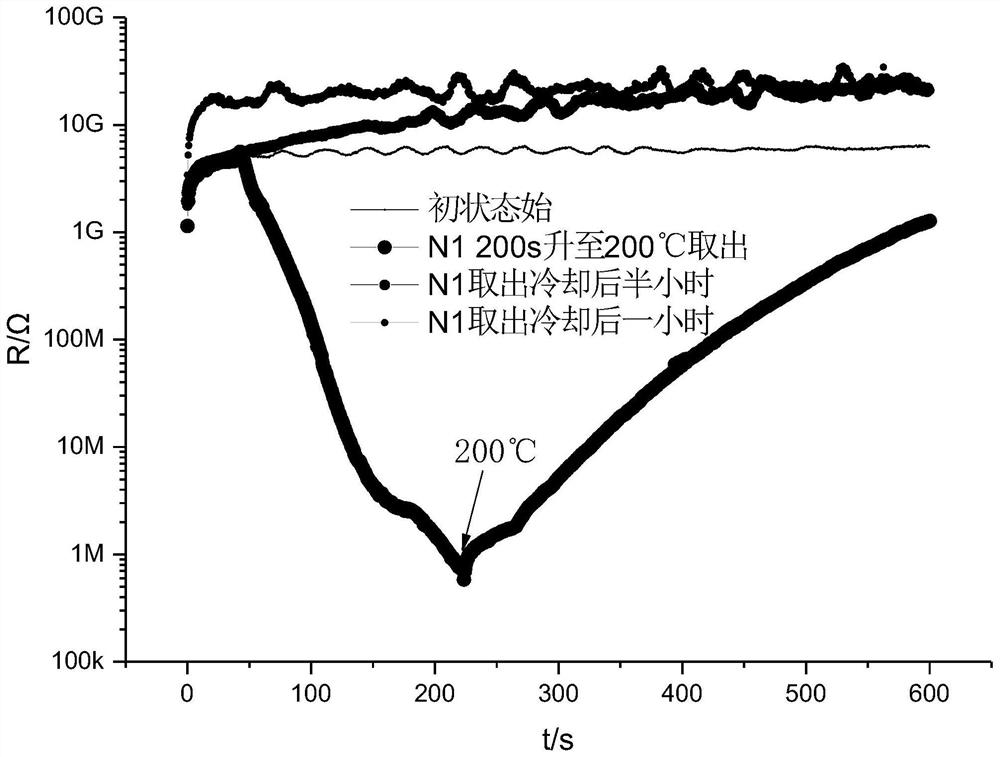

[0049] Load a constant voltage on the STO chip capacitor: 50V DC voltage, and at the same time rapidly heat up to 200°C at a rate of 50°C / min in the rapid annealing furnace. After 100s at this temperature, take the capacitor out of the annealing furnace and place it quickly. Rapidly cool in liquid nitrogen for 2 minutes, then take out the capacitor and let it rise to room temperature naturally in the air. After electrical and heat treatment, the insulation resistance of STO chip capacitors can be greatly increased by 10 to 30 times without changing the capacitance value, loss and capacitance temperature coefficient of the capacitor, and the resistance consistency is also improved. like image 3 Shown is the graph of the variation of insulation resistance with measurement time before and after STO chip capacitor treatment. It can be seen from the figure that after thermal and electrical treatment, the insulation resistance value of the chip capacitor rises from the original 1....

Embodiment 2

[0051] Load a constant voltage on the STO chip capacitor: 50V DC voltage, and at the same time in the rapid annealing furnace at a rate of 40°C / min, rapidly heat up to 180°C, and after 120s at this temperature, take the capacitor out of the annealing furnace and place it quickly Rapidly cool in liquid nitrogen for 1 minute, then take out the capacitor and let it rise to room temperature naturally in the air. After electrical and heat treatment, the insulation resistance of STO chip capacitors can be greatly increased by 10 to 30 times without changing the capacitance value, loss and capacitance temperature coefficient of the capacitor, and the resistance consistency is also improved.

Embodiment 3

[0053] Load a constant voltage on the STO chip capacitor: 50V DC voltage, and at the same time in the rapid annealing furnace at a rate of 60°C / min, rapidly raise the temperature to 220°C, and after 80s at this temperature, take the capacitor out of the annealing furnace and place it quickly Rapidly cool in liquid nitrogen for 3 minutes, then take out the capacitor and let it rise to room temperature naturally in the air. After electrical and heat treatment, the insulation resistance of STO chip capacitors can be greatly increased by 10 to 30 times without changing the capacitance value, loss and capacitance temperature coefficient of the capacitor, and the resistance consistency is also improved.

[0054] The above-mentioned embodiments 1-3 adopt a simple and easy physical method, that is, the STO chip capacitor is subjected to rapid heating and cooling treatment under the condition of applying voltage, and the insulation resistance and withstand voltage value of the chip capa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com