A Method for Improving the Insulation Performance of Large-scale Motors on Site

A large-scale motor and insulation performance technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of long maintenance period, affecting production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

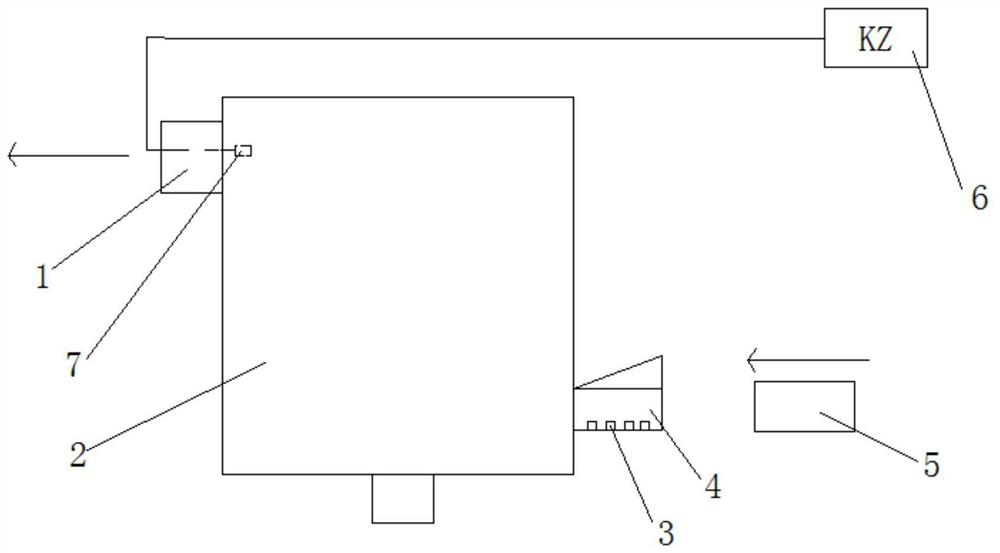

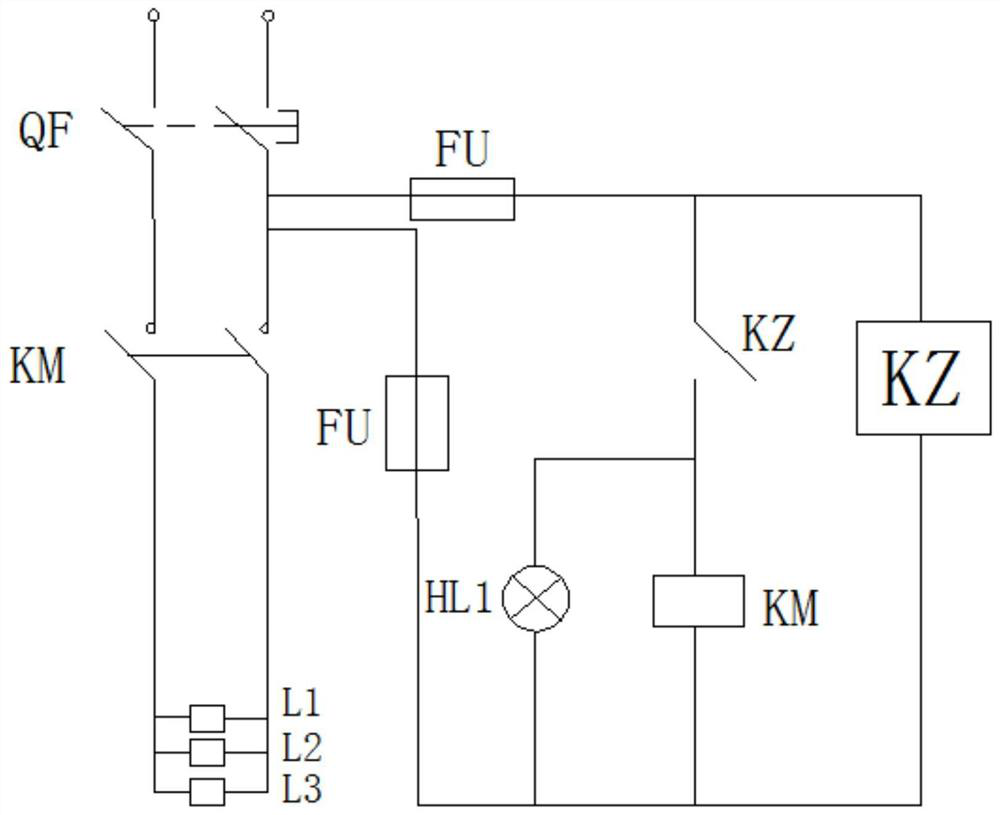

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] This embodiment further illustrates the technical solution of the present invention by taking the main motor of side thruster for marine as an example, wherein the motor is a squirrel-cage asynchronous motor, and its working parameters are: C4W500LA6 Voltage: 380V Frequency: 50HZ Current: 2140A Power: 1140KW, This embodiment is mainly aimed at drying the stator winding of the squirrel-cage asynchronous motor. A method for improving the insulation performance of a large motor on site provided by the present invention includes:

[0024] S010, the current drying step, start the drying power supply, apply current to the winding inside the motor from the drying power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com