Conductive composition mfg. method and conductive paste mfg. method

A manufacturing method and composition technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, conductive adhesives, cable/conductor manufacturing, etc., can solve the problem of mixing metal particle metal particle slurry and ceramic particle slurry Insufficient dispersion, hindering the improvement of the yield of electronic components, and the inability to disperse metal particles, etc., to achieve the effects of prolonging life, less short-circuit defects, and high insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

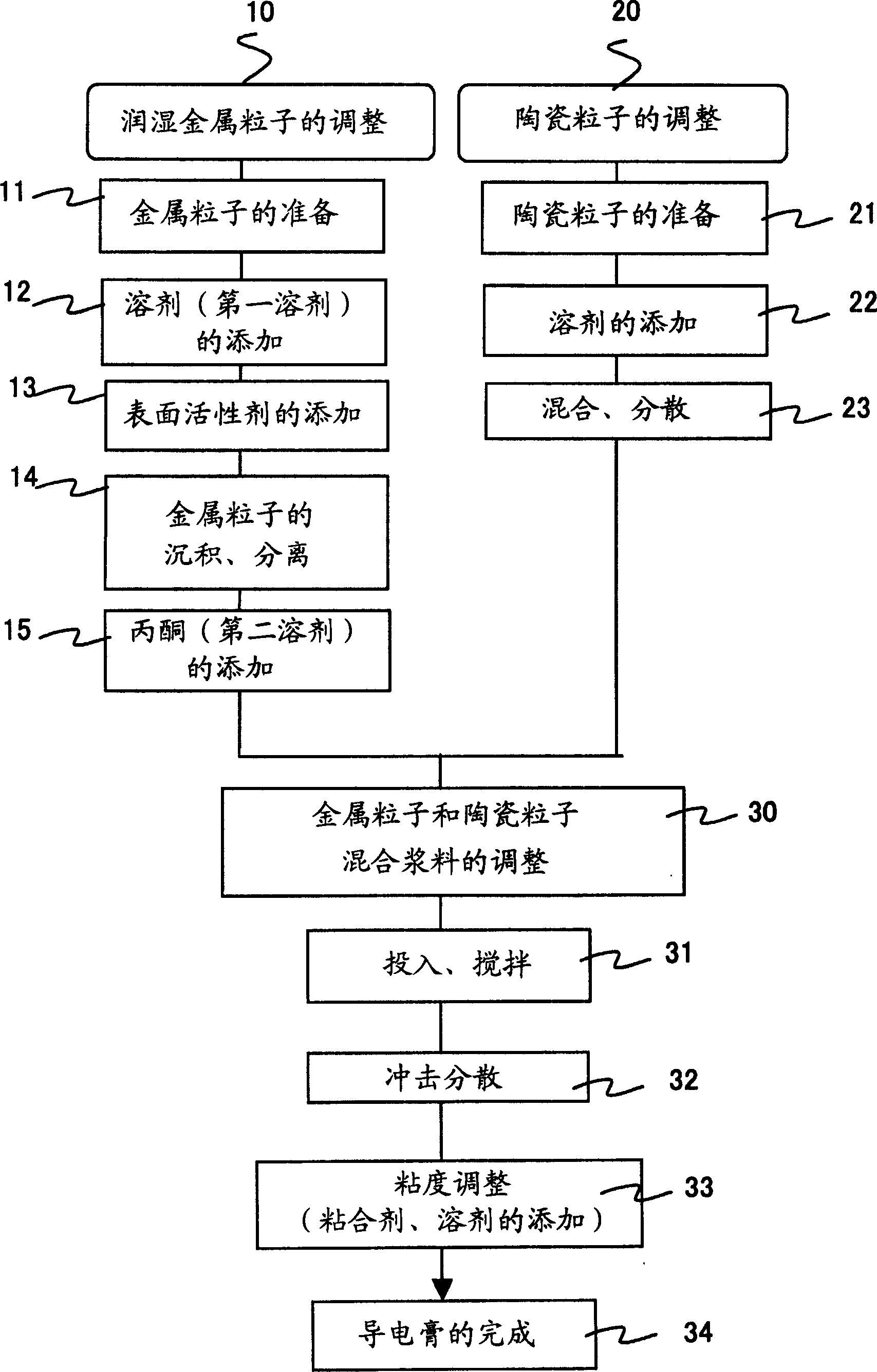

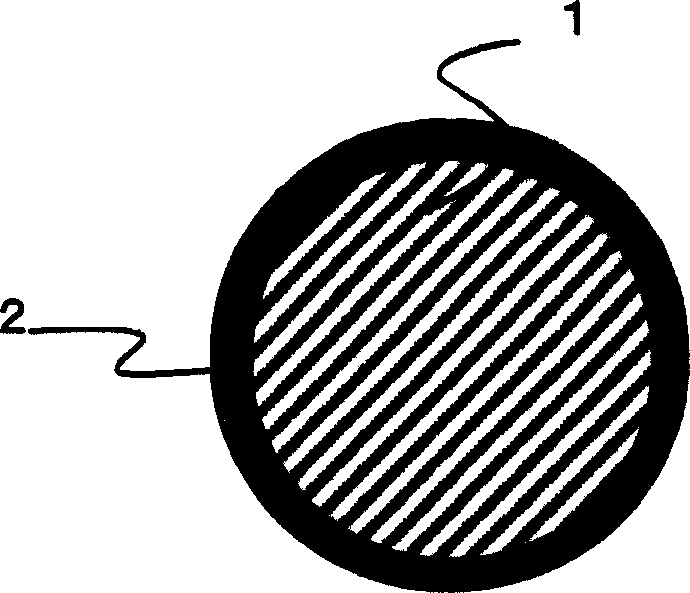

[0084] Ni metal particles having an average particle diameter of 0.4 μm obtained by the gas phase chemical reaction method were washed with water. After washing with water, a slurry containing Ni metal particles and water was obtained. This slurry contained 80 parts by weight of water with respect to 100 parts by weight of Ni metal particles.

[0085] With this slurry, 3 to 30 parts by weight of terpineol as a solvent and 0.05 to 10.0 parts by weight of a cationic surfactant were mixed and stirred. The Ni metal particles are deposited and separated from the water. 0.3 to 30 parts by weight of acetone as a second solvent is added to the separated Ni metal particles, and the added acetone is evaporated together with water to remove water adhering to the Ni metal particles. Ni metal particles are covered and wetted by terpineol and / or surfactant. The average particle diameter of the obtained Ni metal particles was 0.4 μm.

[0086] To 100 parts by weight of the slurry, 50 wt% ...

Embodiment 2

[0094] The sheet of Example 2 was produced in the same manner as in Example 1 except that the pressure at the time of impact dispersion was different. The pressure at the time of the impact dispersion of Example 2 is 9.8×10 7 Pa(1000kgf / cm 2 ).

Embodiment 3

[0100] The flakes of Example 3 were produced in the same manner as in Example 1 except that the pressure at the time of impact dispersion was different. The pressure at the time of the impact dispersion of Example 3 is 1.96×10 7 Pa(200kgf / cm 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com