Docking method of 10kV crosslinked polyethylene cable

A cross-linked polyethylene and cable technology, which is applied in the direction of cable joints, cable installation, cable accessories, etc., can solve the problems of breakdown short circuit, short circuit fault to ground, and low insulation performance of joints, and achieve the improvement of insulation resistance value and excellent performance. The effect of moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

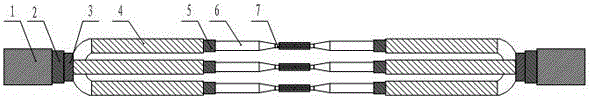

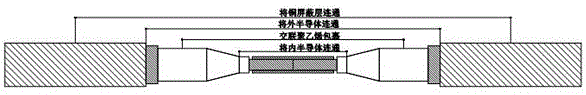

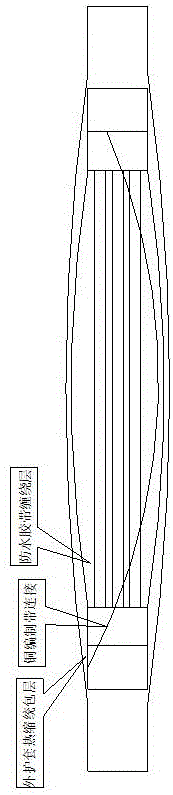

[0018] like Figure 1~3 As shown, a 10kV XLPE cable docking method, the specific steps are:

[0019] (1) Align the two sections of cables to be connected, strip 600mm of the cable outer sheath 1 from each port, strip 550mm of the cable protective steel armor 2 from each port, and strip 500mm of the inner cable from each port. Sheath layer 3 and remove the cable filler;

[0020] (2) First put the radiation heat shrinkable tube into one end of the cable, and use it after the cable is docked;

[0021] (3) Then peel off 300mm of copper shielding layer 4 from each port, and strip off 250mm of semi-conductive layer 5 from each port; measure the length of the copper crimping tube connecting the cable core and take 1 / 2 of the length plus 5mm as the required According to the basis of stripping the main insulation of the cable to expose the conductive core, the main insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com