Integrated insulating joint

An insulating joint, integrated technology, applied in the direction of pipe/pipe joint/pipe fittings, through components, mechanical equipment, etc., can solve the problems of shortened pipeline life, long production cycle, leakage of insulating joints, etc., to improve tensile performance and The effect of bending moment resistance, improving the qualified rate of finished products, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

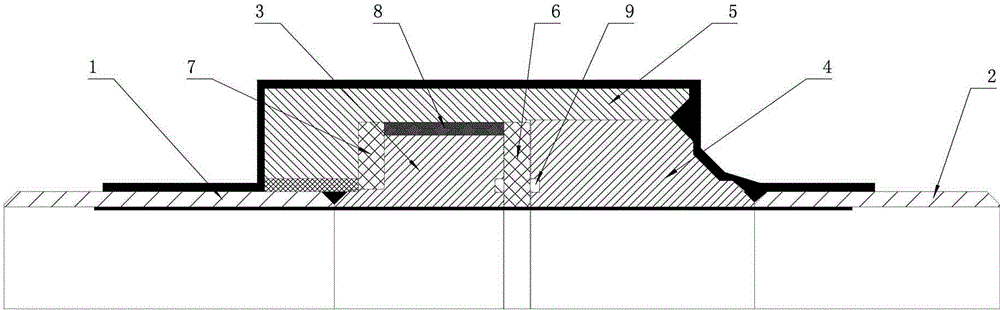

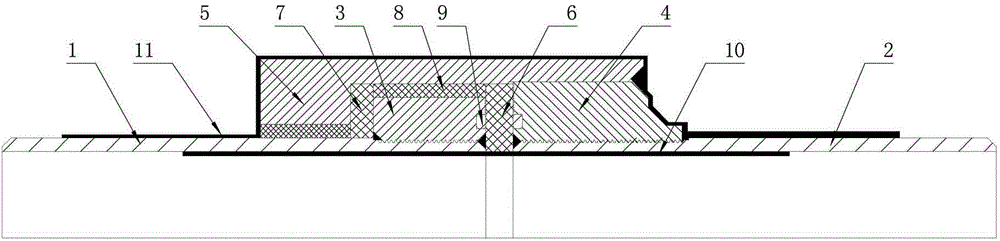

[0045] Example: such as figure 2 As shown, the integral insulating joint described in this embodiment includes a left steel short pipe 1, a right steel short pipe 2, a left flange 3, a right flange 4, a joint sleeve 5, a first insulating seal 6, a second Two insulating seals 7, insulating filling materials 8 and insulating sealing rings 9, the left short steel pipe 1 is fixedly connected to the left flange 3, the right short steel pipe 2 is fixedly connected to the right flange 4, and the The left flange 3 and the right flange 4 are fixedly connected by a first insulating seal 6 and an insulating sealing ring 9, the outer wall of the left flange 3 and the outer wall of the right flange 4 are sleeved with a joint sleeve 5, and the left Between the outer wall of the flange 3 and the joint sleeve 5 there is an insulating filler 8 and a second insulating seal 7, the outer wall of the left short steel pipe 1 has external threads, the inner wall of the left flange 3 has internal th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com