Automobile drawing die

A technology for drawing dies and automobiles, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the structural strength of parts, simple geometry and small curvature, and increasing the tensile resistance of blanks, so as to improve work efficiency. , The appearance is smooth and tidy, and the effect of improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

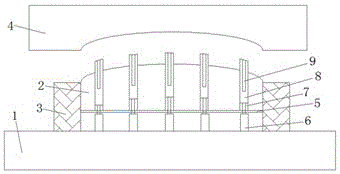

[0015] refer to figure 1 , an automobile drawing die, comprising a base 1, the top of the base 1 is provided with a lower die 2, the outside of the lower die 2 is provided with a blank holder 3, the top of the blank holder 3 is provided with an upper die 4, and the inside of the lower die 2 is provided with There is a fixed plate 5, a telescopic device 6 is arranged under the fixed plate 5, the top of the telescopic device 6 extends to the top of the fixed plate 5, a storage slot 7 is arranged above the fixed plate 5, and a rod-shaped movable mold is arranged in the storage slot 7 8. The bottom of the rod-shaped movable mold 8 is fixedly connected with the top of the telescopic device 6, and the outer wall of the rod-shaped movable mold 8 is slidingly connected with the inner wall of the storage tank 7. The inside of the rod-shaped movable mold 8 is provided with a heating device 9, and the heating device 9 Located on the top of the rod-shaped movable mold 8, the top of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com