High temperature soldering paste special for semiconductors

A high-temperature soldering and semiconductor technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high frequency of solder paste scraping, low insulation resistance value, low product wettability, etc., to reduce the The frequency of scraping solder paste, the effect of improving insulation resistance value and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

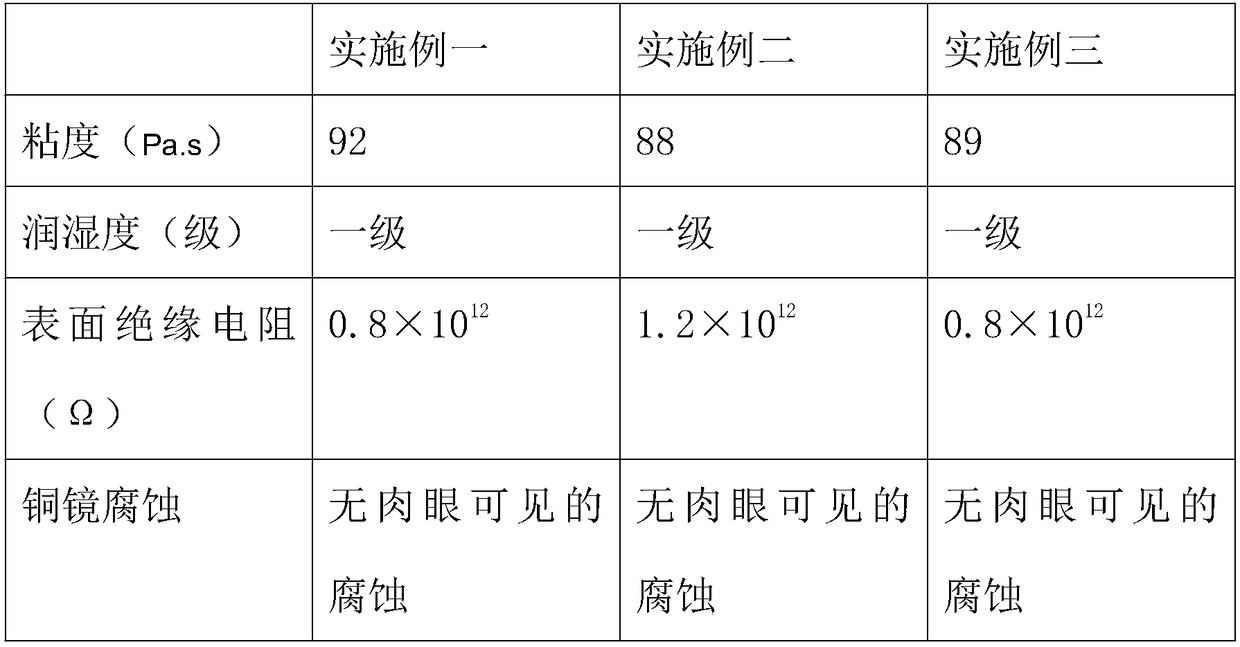

Examples

Embodiment 1

[0022] High-temperature solder paste for semiconductors, composed of flux and tin-based alloy powder with a weight ratio of 10%:90%, the flux includes the following raw materials in percentage by weight: thixotropic agent 4%, active agent 4%, polymerized rosin 20% %, hydrogenated rosin 10%, organic solvent is 62%, tin base alloy powder is made up of tin Sn 5%, lead Pb 92.5%, silver Ag 2.5%, thixotropic agent comprises the raw material of following weight percentage: ethylene bis stearamide 1%, high-performance amide wax micropowder 2%, polyamide-modified hydrogenated castor oil derivative 1%, the mixture 96% of butyl carbitol-terpineol; Active agent comprises the raw material of following percentage by weight: decyldecyl Tetraacid 2%, fluorosurfactant 0.5%, 2-ethylimidazole 2%, butyl carbitol-terpineol mixture 95.5%;

[0023] The preparation method comprises the following steps:

[0024] S1. Put the above-mentioned polymerized rosin, hydrogenated rosin and organic solvent in ...

Embodiment 2

[0029] High-temperature solder paste for semiconductors, composed of flux and tin-based alloy powder with a weight ratio of 13%:87%, the flux includes the following raw materials in percentage by weight: thixotropic agent 10%, active agent 10%, polymerized rosin 22 %, hydrogenated rosin 11%, organic solvent is 57%, tin base alloy powder is made up of tin Sn 5%, lead Pb 92.5%, silver Ag 2.5%, thixotropic agent comprises the raw material of following weight percent: ethylene bis stearamide 3%, high-performance amide wax micropowder 4%, polyamide-modified hydrogenated castor oil derivative 3%, the mixture of butyl carbitol-terpineol has 90%; Active agent comprises the raw material of following percentage by weight: decyl Myristic acid 5%, fluorosurfactant 1.2%, 2-ethylimidazole 4%, butyl carbitol-terpineol mixture 89.8%;

[0030] The preparation method comprises the following steps:

[0031] S1. Put the above-mentioned polymerized rosin, hydrogenated rosin and organic solvent in...

Embodiment 3

[0036] High-temperature solder paste for semiconductors, composed of flux and tin-based alloy powder with a weight ratio of 15%:85%, the flux includes the following raw materials in percentage by weight: thixotropic agent 16%, active agent 16%, polymerized rosin 25% %, hydrogenated rosin 13%, organic solvent 30%, tin base alloy powder is made up of tin Sn 5%, lead Pb 92.5%, silver Ag 2.5%, thixotropic agent comprises the raw material of following weight percent: ethylene bis stearamide 6 %, high-performance amide wax micropowder 5%, polyamide-modified hydrogenated castor oil derivative 5%; active agent comprises the raw material of following percentage by weight: decyl tetradecanoic acid 8%, fluorosurfactant 2%, 2-ethane 6% imidazole, 84% mixture of butyl carbitol-terpineol;

[0037] The preparation method comprises the following steps:

[0038] S1. Put the above-mentioned polymerized rosin, hydrogenated rosin and organic solvent in the weight percentage and mix them in a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com