Battery piece welding process for photovoltaic power generation transverse connection assembly

A cell welding, photovoltaic power generation technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of affecting the welding effect of solar photovoltaic modules, poor cell welding effect, and inability to guarantee welding wettability, etc. Easy to promote and use, avoid welding offset or contact instability, and good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

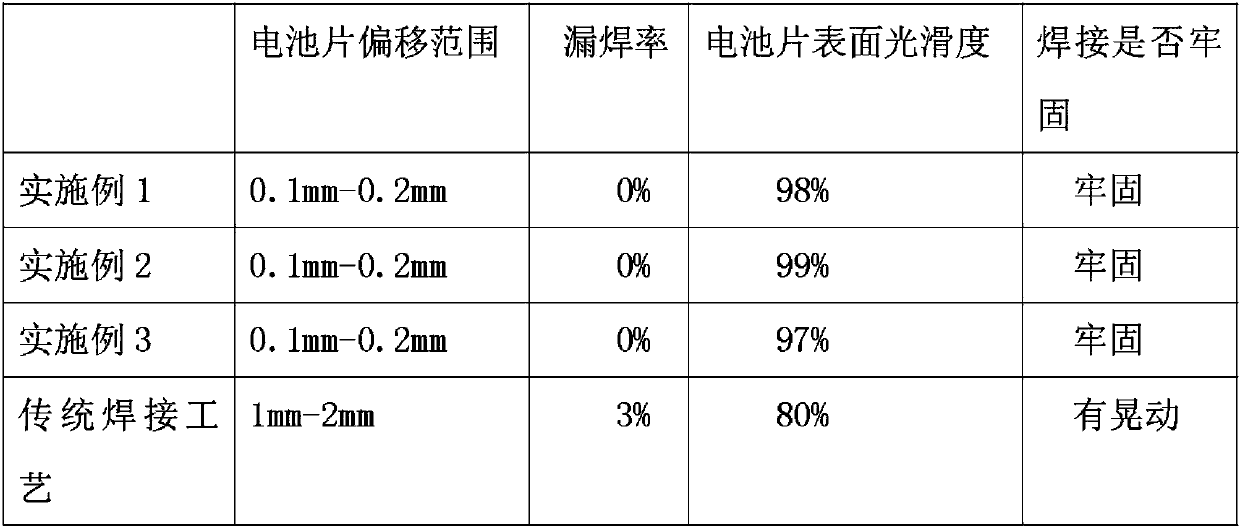

Embodiment 1

[0025] A battery sheet welding process for photovoltaic power generation cross-connection modules, comprising the following steps:

[0026] Step 1: Determine the number of cells, check whether the cells have missing corners, cracks, etc., confirm that the cells are complete, and then take a cell and place it face up;

[0027] Step 2: Select a clean interconnection strip and place it in the soaking box, then add flux, soak the interconnection strip for a period of time with the flux, when the interconnection strip is soaked, take it out and wrap it with a dust-free cotton cloth for later use, the flux has the following parts by weight Composition: 10 parts of hydrogenated rosin, 10 parts of modified epoxy resin, 2 parts of fatty acid polyoxyethylene resin, 2 parts of polyoxyethylene alkylamine, 1 part of diethylene glycol butyl ether, 1 part of ethanol, 1 part of aniline phosphate, 1 part of triethanolamine, 1 part of hydrogenated castor oil derivatives, 2 parts of additives, w...

Embodiment 2

[0033] A battery sheet welding process for photovoltaic power generation cross-connection modules, comprising the following steps:

[0034] Step 1: Determine the number of cells, check whether the cells have missing corners, cracks, etc., confirm that the cells are complete, and then take a cell and place it face up;

[0035] Step 2: Select a clean interconnection strip and place it in the soaking box, then add flux, soak the interconnection strip for a period of time with the flux, when the interconnection strip is soaked, take it out and wrap it with a dust-free cotton cloth for later use, the flux has the following parts by weight Composition: 15 parts of hydrogenated rosin, 12 parts of modified epoxy resin, 3 parts of fatty acid polyoxyethylene resin, 2.5 parts of polyoxyethylene alkylamine, 1.5 parts of diethylene glycol butyl ether, 1.5 parts of ethanol, 2 parts of aniline phosphate, 2 parts of triethanolamine, 2 parts of hydrogenated castor oil derivatives, and 3 parts ...

Embodiment 3

[0041] A battery sheet welding process for photovoltaic power generation cross-connection modules, comprising the following steps:

[0042] Step 1: Determine the number of cells, check whether the cells have missing corners, cracks, etc., confirm that the cells are complete, and then take a cell and place it face up;

[0043]Step 2: Select a clean interconnection strip and place it in the soaking box, then add flux, soak the interconnection strip for a period of time with the flux, when the interconnection strip is soaked, take it out and wrap it with a dust-free cotton cloth for later use, the flux has the following parts by weight Composition: 20 parts of hydrogenated rosin, 15 parts of modified epoxy resin, 4 parts of fatty acid polyoxyethylene resin, 3 parts of polyoxyethylene alkylamine, 2 parts of diethylene glycol butyl ether, 2 parts of ethanol, 3 parts of aniline phosphate, 3 parts of triethanolamine, 3 parts of hydrogenated castor oil derivatives, and 4 parts of addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com