No-wash halogen-free flux and low-temperature soldering tin wire

A low-temperature soldering and flux technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of needing cleaning process, high cost, unfavorable environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

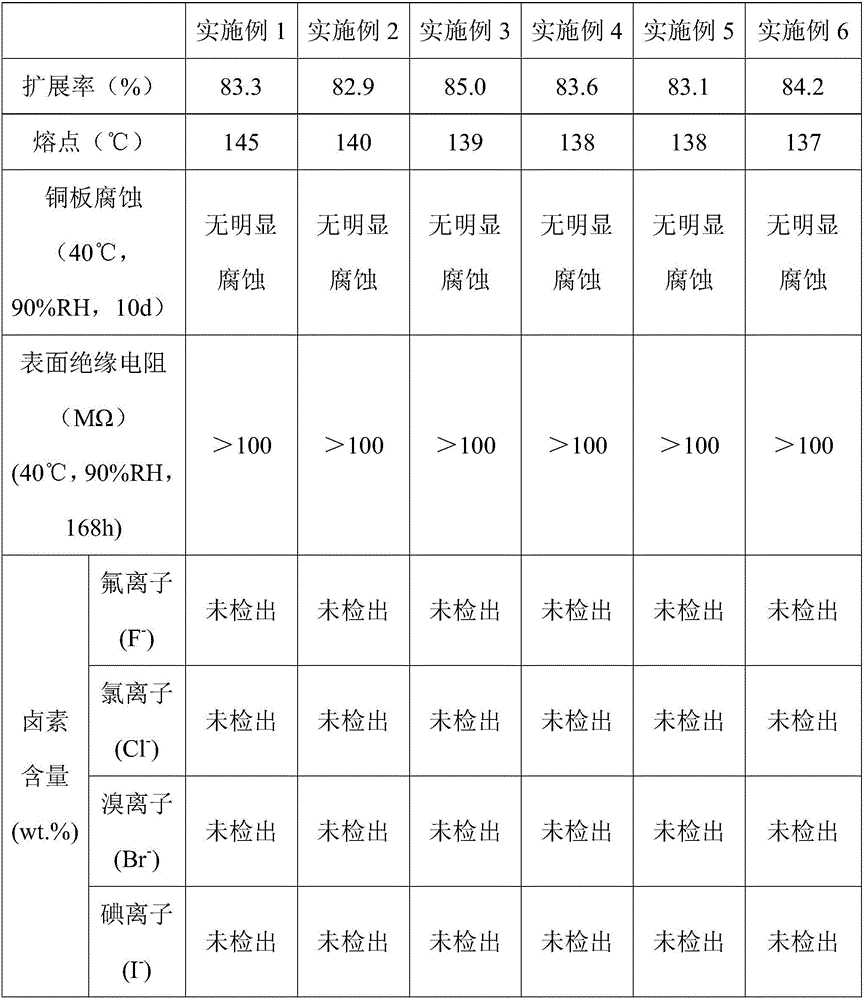

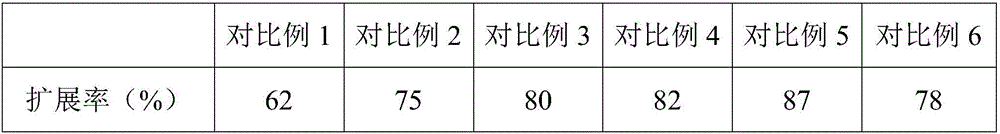

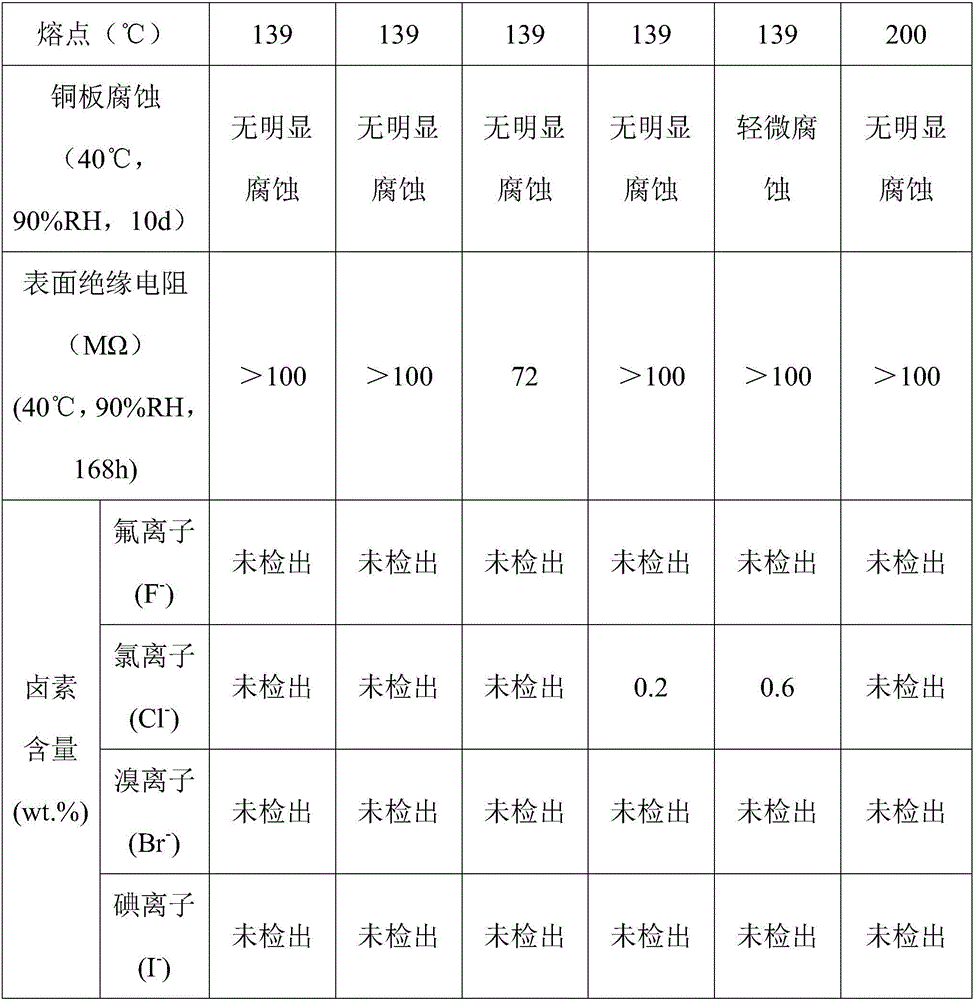

Examples

Embodiment 1

[0053] 1) Preparation of no-clean halogen-free flux: by weight percentage, the following raw materials were weighed: 20% phenolic resin, 12% acrylic resin, 61% isopropanol, 1% malic acid, 1.5% salicylic acid acid, 1.5% succinic acid, 1.5% adipic acid, 0.5% alkylphenol ethoxylates, 0.3% hydrogenated castor oil, 0.5% tolyltriazole and 0.2% menthol , in which phenolic resin and acrylic resin form a synthetic resin, and malic acid, salicylic acid, succinic acid and adipic acid are compounded to form an organic acid activator; the above raw materials are mixed to prepare a no-clean halogen-free flux.

[0054] 2) Preparation of low-temperature solder wire: by weight percentage, the SnAgBi alloy is prepared as raw material with 0.5% Ag, 44.5% Bi and the Sn of the balance; ) prepared 2% no-cleaning halogen-free flux as raw material to prepare low-temperature solder wire.

Embodiment 2

[0056] 1) Preparation of no-clean halogen-free soldering flux: by weight percentage, take the following raw materials: 20% phenolic resin, 15% vinyl chloride resin, 58% isopropanol, 0.8% citric acid, 1.5% trans Oleic acid, 1.5% succinic acid, 1.5% benzoic acid, 0.5% octylphenol ethoxylate, 0.4% polyamide wax, 0.6% benzotriazole and 0.2% menthol, phenolic Resin and vinyl chloride resin form a synthetic resin, and citric acid, elaidic acid, succinic acid and benzoic acid are compounded to form an organic acid activator; the above raw materials are mixed to prepare a non-cleaning halogen-free flux.

[0057] 2) Preparation of low-temperature solder wire: by weight percentage, the SnAgBi alloy is prepared as raw material with 0.5% Ag, 63.5% Bi and the Sn of the balance; ) prepared 2.2% no-clean halogen-free flux as raw material to prepare low-temperature solder wire.

Embodiment 3

[0059] 1) Preparation of no-clean halogen-free flux: by weight percentage, the following raw materials were weighed: 12% polyurethane, 15% phenolic resin, 65% isopropanol, 0.8% glutaric acid, 1.8% butanediol acid, 1.8% malic acid, 1.1% benzoic acid, 0.8% sorbitan monolaurate, 0.4% hydrogenated castor oil, 0.6% benzotriazole and 0.7% hexamethylenediamine, of which Polyurethane and phenolic resin form a synthetic resin, and glutaric acid, succinic acid, malic acid and benzoic acid are compounded to form an organic acid activator; the above raw materials are mixed to prepare a no-cleaning halogen-free flux.

[0060] 2) Preparation of low-temperature solder wire: by weight percentage, the SnAgBi alloy is prepared as raw material with 2.5% Ag, 55.5% Bi and the Sn of the balance; ) prepared 2% no-cleaning halogen-free flux as raw material to prepare low-temperature solder wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com