Dielectric ceramic composition and ceramic electronic component

A technology of dielectric ceramics and composites, which is applied to fixed capacitance components, ceramics, electrical components, etc., and can solve problems such as low relative permittivity, inability to obtain high-capacity capacitors, and degradation of characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

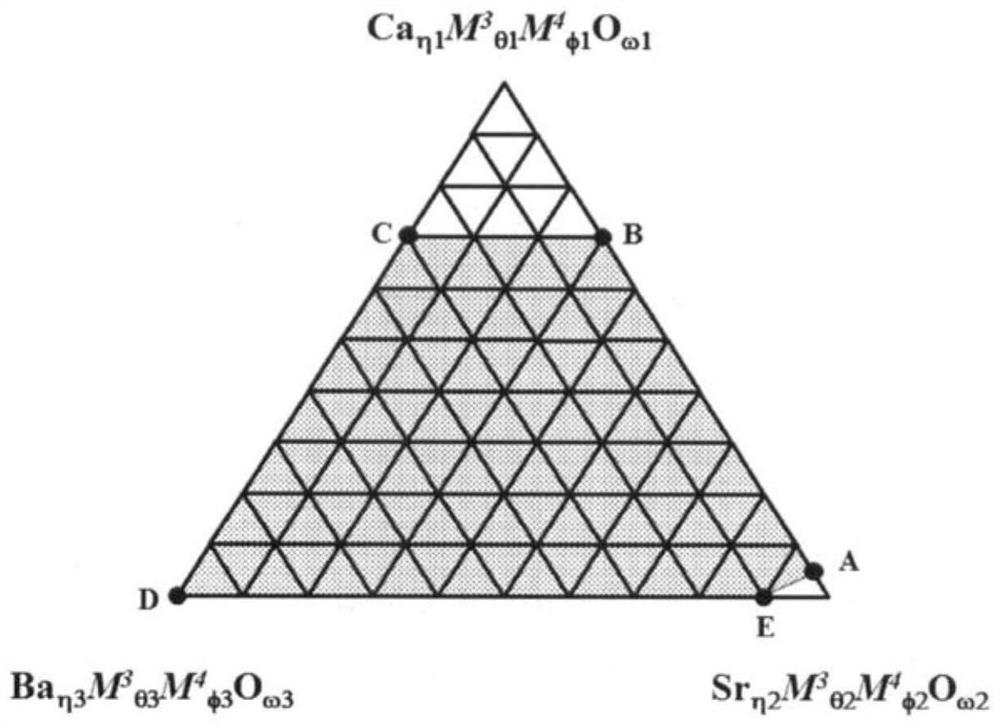

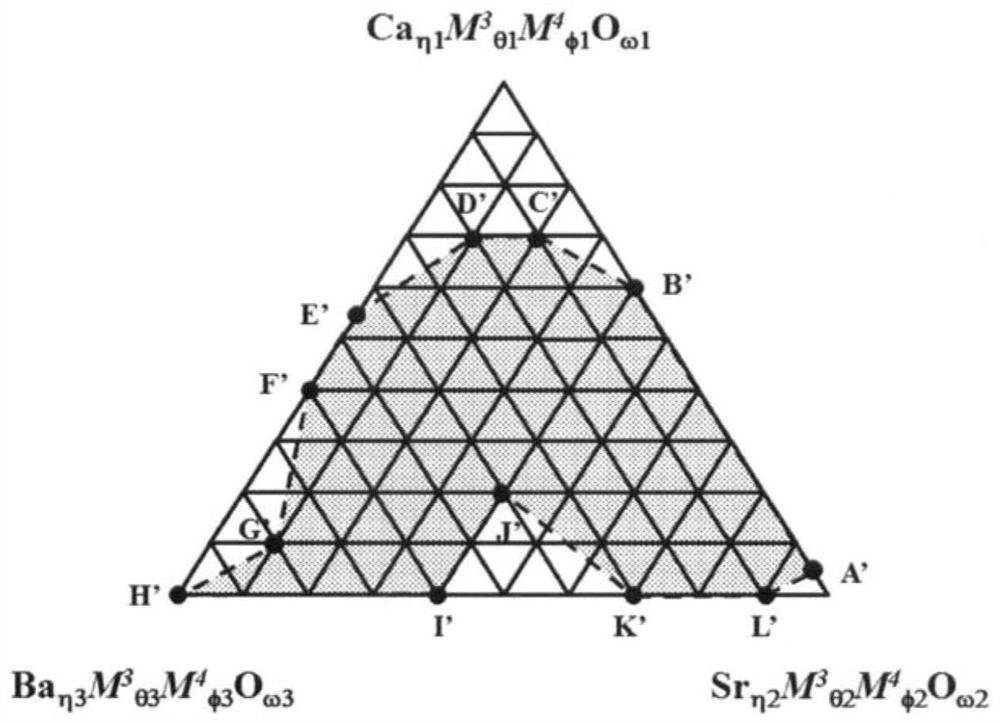

Method used

Image

Examples

Embodiment

[0169] First, a confirmation test was carried out on regulation of the content of the first component and the effect of adding Mn oxide (reference samples 1 to 90 and reference samples 91 to 107).

reference example 1

[0171] (1) Preparation of Dielectric Ceramic Composition Reference Samples 1-90

[0172] As a starting material for the first component, CaCO 3 , SrCO 3 、BaCO 3 、TiO 2 , ZrO 2 , SnO 2 , Nb 2 o 5 、 Ta 2 o 5 , V 2 o 5 The respective powders were weighed so that the ratios shown in Table 1, Table 3, and Table 5 were obtained in terms of oxides, and wet mixing was performed for 20 hours using pure water using a ball mill.

[0173] Next, each of the obtained mixtures was dried at 100° C., then calcined at 750° C. to 900° C. for 3 hours in the air, and finely pulverized by a ball mill again to obtain a dielectric raw material for the first component.

[0174] In addition, as a second component, MnCO was weighed separately 3 18.2mg, MgO 32mg, SiO 2 58.6mg, Y 2 o 3 89.5 mg, and these mixed substances were prepared as raw materials for the second component. Wherein, in the reference sample 43, the raw materials for the second component only use SiO 2 MnCO 3 , MgO an...

reference example 2

[0213] The first component raw material was weighed so that it had the composition shown in Table 7 in terms of oxides, and MnCO as the second component raw material was weighed. 3 and SiO 2 Except weighing so as to have the composition shown in Table 7 in terms of oxides, reference samples 91 to 107 were prepared in the same manner as in Reference Example 1, and disc-shaped ceramic capacitors corresponding to the respective samples were obtained. .

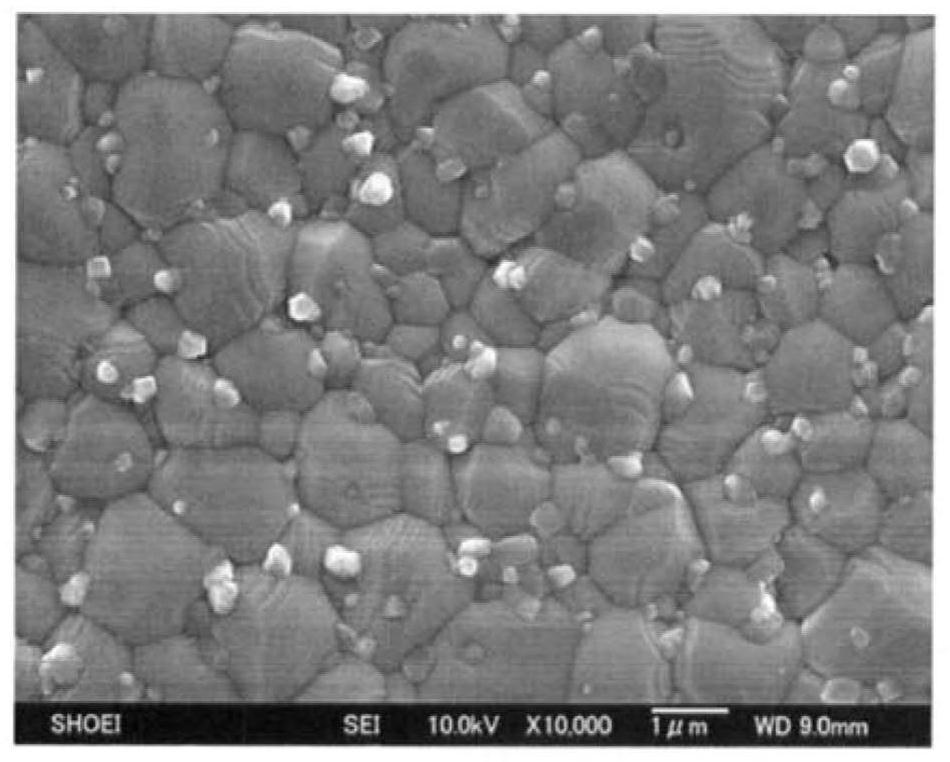

[0214] Thereafter, the particle size, crystal phase, relative permittivity, capacitance change rate, and dielectric loss (tan δ) were measured in the same manner as in Reference Example 1, and the results are shown in Table 8.

[0215] From these results, it can be seen that relative to the total mass of the first component in terms of oxides, in the case of samples whose Mn content in terms of MnO as the second component is 3.500% by mass or less, the relative permittivity and capacitance change Good results were obtained in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com