Submersible motor winding and power supply connecting structure

A technology for power connection and submersible motor, applied in windings, electric components, electrical components, etc., can solve problems affecting the reliability of the motor, and achieve the effect of prolonging the service life, ensuring the fastening strength, and facilitating the lap joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

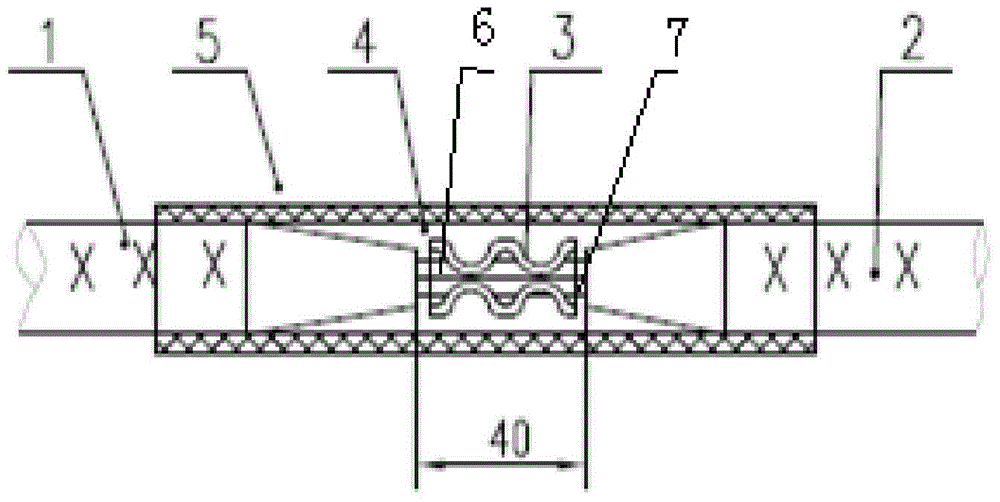

[0011] The present invention is described in more detail according to accompanying drawing now, as figure 1 As shown, a connection structure between a submersible motor winding and a power supply includes a motor winding wire connector 7 and a power cable outlet wire connector 6, and the motor winding wire connector 7 and the power cable outlet wire connector 6 are overlapped together relatively in parallel, And set a metal pipe 3, the metal pipe 3 fastens the motor winding wire joint 7 and the power cable outlet wire joint 6 by means of cold pressure welding, and the metal pipe 3 is covered with a layer of cement 4, and the cement The outer circumference of 4 is flush with the outer surface of the outer sheath of the motor winding wire, the outer diameter of the outer sheath of the motor winding wire and the outer sheath of the power cable lead-out wire is the same, and the outer surface of the cement 4 is covered with a layer of heat-shrinkable sleeve 5 . Since the metal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com