High-contamination-resistant wood-grain-like and sandstone-like coating system and construction method thereof

A technology of coating system and construction method, applied in coating, antifouling/underwater coating, paint containing biocide, etc. The effect of improving the overall life and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

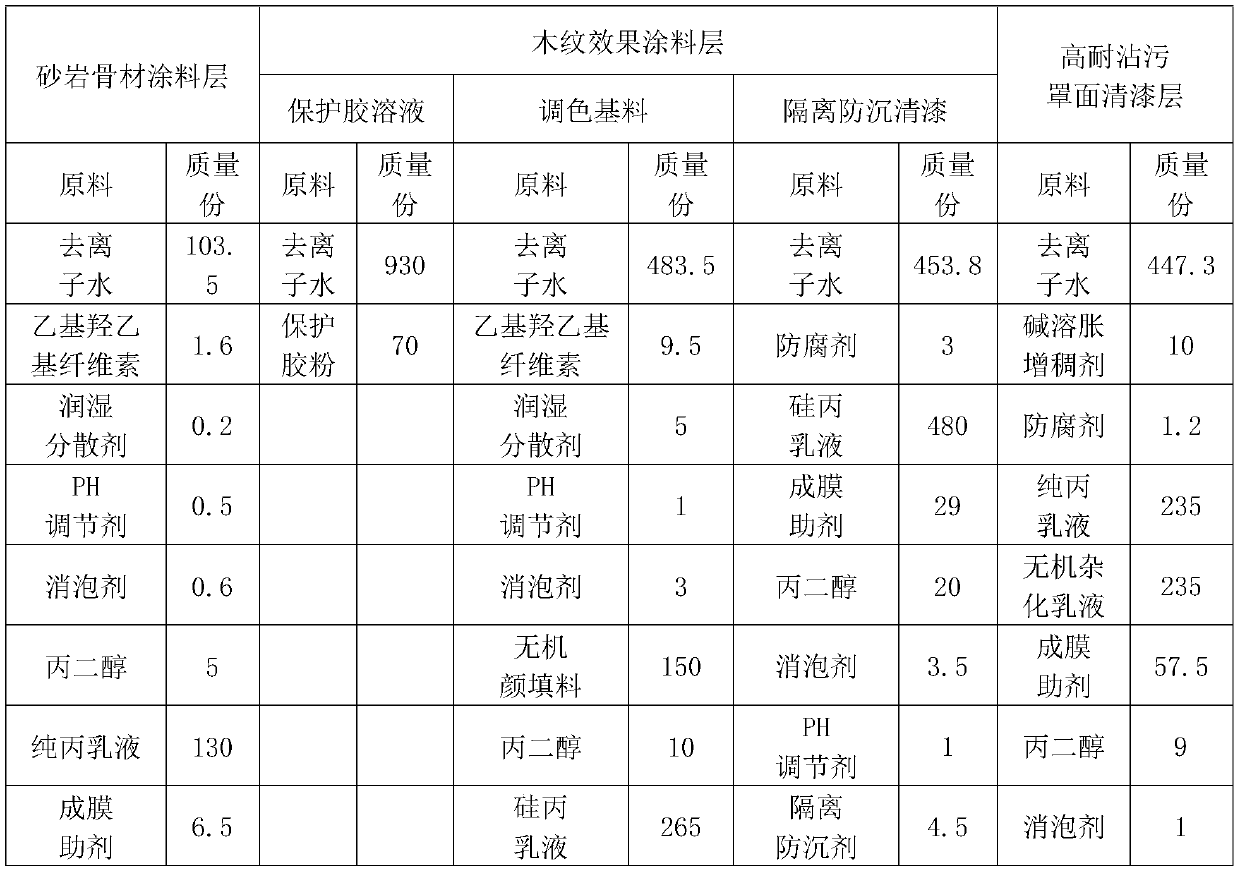

[0027] A coating system with high stain resistance and imitation wood grain sandstone effect, consisting of the materials in the following table:

[0028]

[0029]

[0030] In embodiment one, the construction method of the coating system of high anti-contamination imitation wood grain sandstone effect:

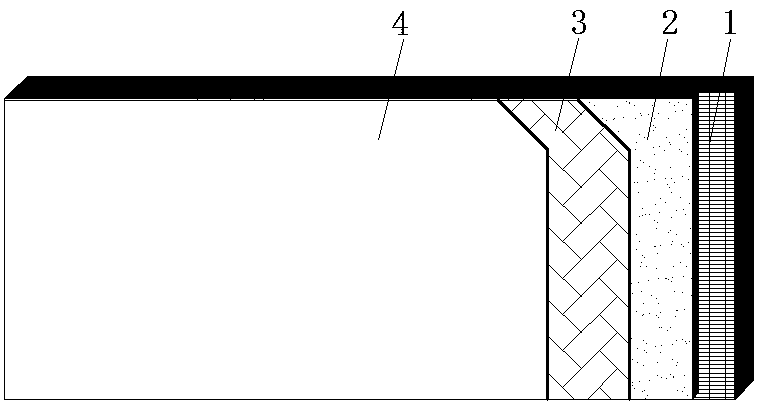

[0031] In the first step, the sandstone aggregate coating layer 2 is sprayed with a special spray gun for real stone paint on the wall body 1 that has been treated with an alkali-resistant sealing primer.

[0032] In the second step, after the sandstone aggregate coating layer 2 is dried for more than 8 hours, the wood grain effect coating layer 3 is sprayed with an internal pressure spray gun.

[0033] In the third step, before the wood grain effect paint layer 3 is surface-dried, use a large hard-bristled brush to quickly brush out the wood grain effect along a fixed direction.

[0034] Step 4: After the wood grain effect paint layer dries for ≥ 24 hours, use a short-...

Embodiment 2

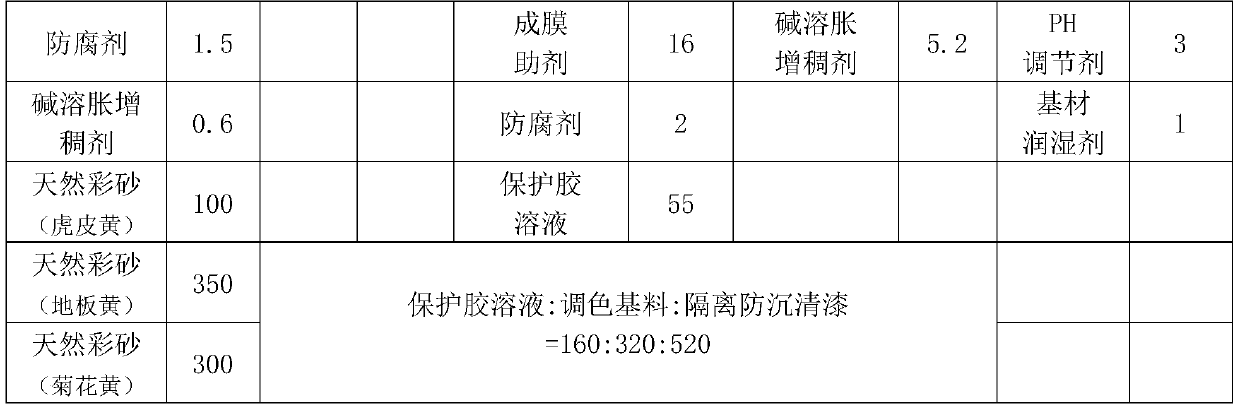

[0037] A coating system with high stain resistance and imitation wood grain sandstone effect, consisting of the materials in the following table:

[0038]

[0039]

[0040] In embodiment two, the construction method of the coating system of high anti-contamination imitation wood grain sandstone effect:

[0041] In the first step, the sandstone aggregate coating layer 2 is sprayed with a special spray gun for real stone paint on the wall body 1 that has been treated with an alkali-resistant sealing primer.

[0042] In the second step, after the sandstone aggregate coating layer 2 is dried for more than 8 hours, the wood grain effect coating layer 3 is sprayed with an internal pressure spray gun.

[0043] In the third step, before the wood grain effect paint layer 3 is surface-dried, use a large hard-bristled brush to quickly brush out the wood grain effect along a fixed direction.

[0044] Step 4: After the wood grain effect paint layer dries for ≥ 24 hours, use a short-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com