Preparation of bacteria cellulose food fresh keeping membrane

A bacterial cellulose, food preservation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, flexible coverings, etc., can solve problems that have not been applied, and achieve white pollution avoidance, good elasticity, and tensile strength Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of bacterial cellulose:

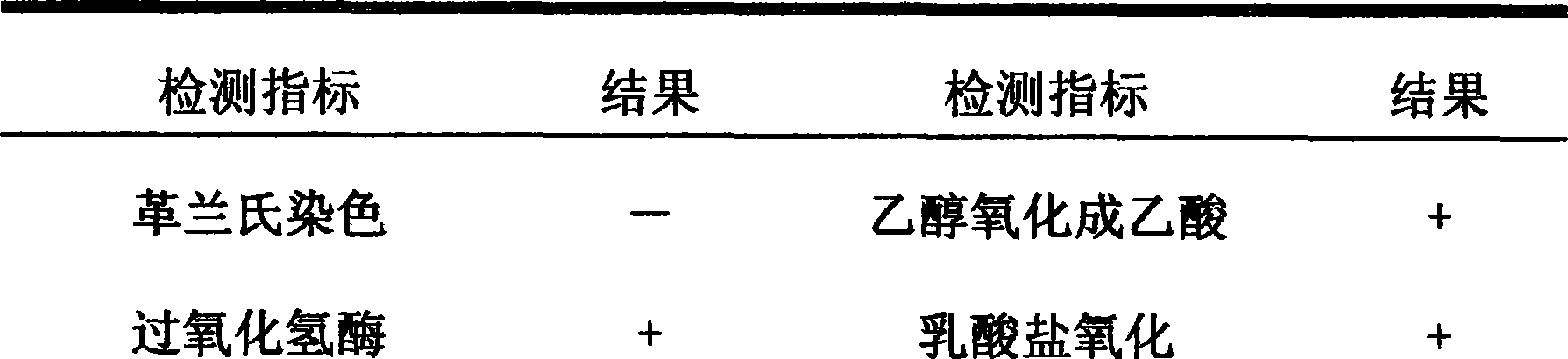

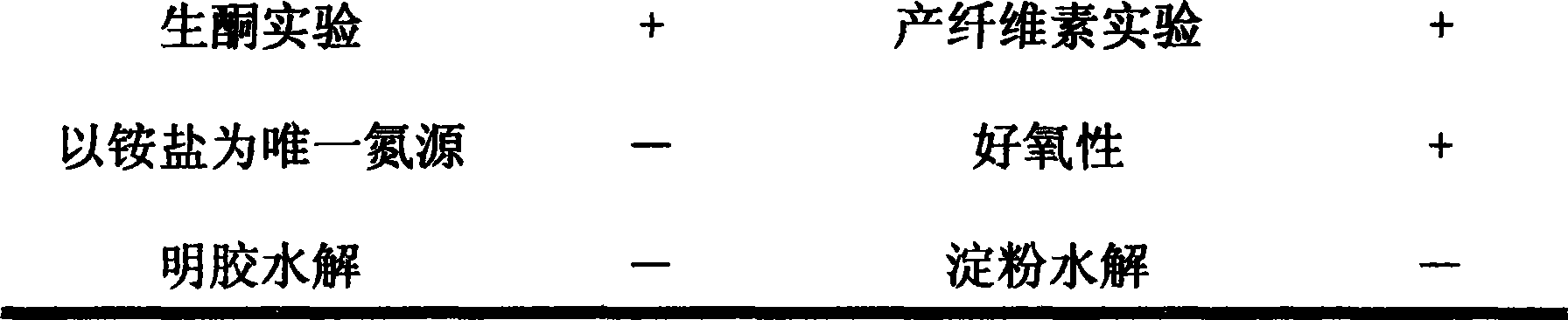

[0028] (1) Cultivation and isolation of Acetobacter xylinum: dilute the vinegar unstrained spirits by 100 times and inoculate in 50 mL enrichment medium. %; yeast extract 0.5%; sodium acetate 0.2%; CaCO 3 1%; use acetic acid to adjust the pH to 5.0; after sterilizing at 121°C for 30 minutes, add 2% ethanol and 0.5% nystatin, and then culture at 28°C for 5 days. is positive. Peel off the gel film on the surface of the enrichment medium, and stick this film carefully on the first separation medium plate; the percentages of each component in the separation medium to the amount of the separation medium are: glucose 5%; Peptone 0.5%; Yeast extract 0.5%; Na 2 HPO 4 12H 2 O 0.2%; KH 2 PO 4 0.1%; MgSO 4 ·7H 2 O0.025%; 0.2% citric acid; 2% agar; pH5.8; . Place the plate at 28°C for 48 hours, then pick a single colony and insert it into the slant, and then separate it by streaking three times in a row to obtain the pure strain. ...

Embodiment 2

[0031] (1) Modification of bacterial cellulose:

[0032]After the bacterial cellulose prepared in Example 1 was swollen with acetic acid for 2 hours at 20°C, it was esterified with acetic anhydride and acetic acid under the action of a concentrated sulfuric acid catalyst with a weight percentage of 98% under normal pressure. Reaction generates bacterial cellulose acetate, wherein, the mass parts ratio of bacterial cellulose and acetic anhydride is 1:6, the mass parts ratio of acetic anhydride and acetic acid is 1:3, and the concentrated sulfuric acid catalyst consumption is bacterial cellulose 0.6% of the mass, the reaction temperature is 60° C., and the time is 2 hours, to obtain a yellow bacterial cellulose acetate sol; then add water to precipitate the bacterial cellulose acetate, and then add 5% by weight of hydrogen oxide to bleach. Filter and dry at 60°C for 2 hours to obtain modified bacterial cellulose.

[0033] (2) Production of bacterial cellulose food preservation ...

Embodiment 3

[0036] (1) Modification of bacterial cellulose:

[0037] The bacterial cellulose obtained in Example 1 was swollen with acetic acid at 40°C for 1 hour, and then esterified with acetic anhydride and acetic acid under the action of a 98% concentrated sulfuric acid catalyst at normal pressure to generate acetic acid Bacterial cellulose, wherein, the mass parts ratio of bacterial cellulose and acetic anhydride is 1:7, the mass parts ratio of acetic anhydride and acetic acid is 2:7, and the concentrated sulfuric acid catalyst consumption is 0.7% of the bacterial cellulose quality , the reaction temperature was 70°C, and the time was 2.5 hours to obtain a yellow bacterial cellulose acetate sol; then add water to precipitate the bacterial acetate cellulose, then add 5% hydrogen peroxide for bleaching, filter, and Dry at 70°C for 1.5 hours to obtain modified bacterial cellulose.

[0038] (2) Production of bacterial cellulose food preservation film:

[0039] The raw material parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com