Method for producing ethanol through acetic acid esterification-hydrogenation

A technology of acetic esterification and ethyl acetate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve good technical effects, flexible selection of product specifications, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

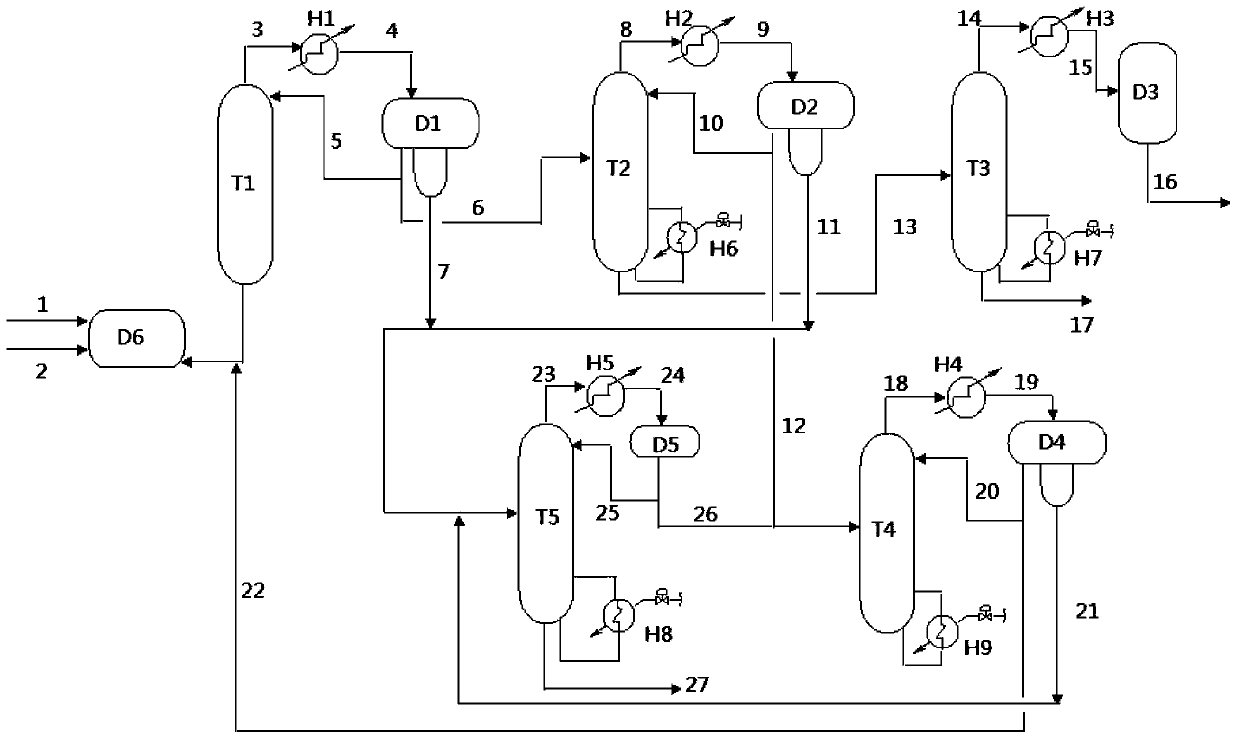

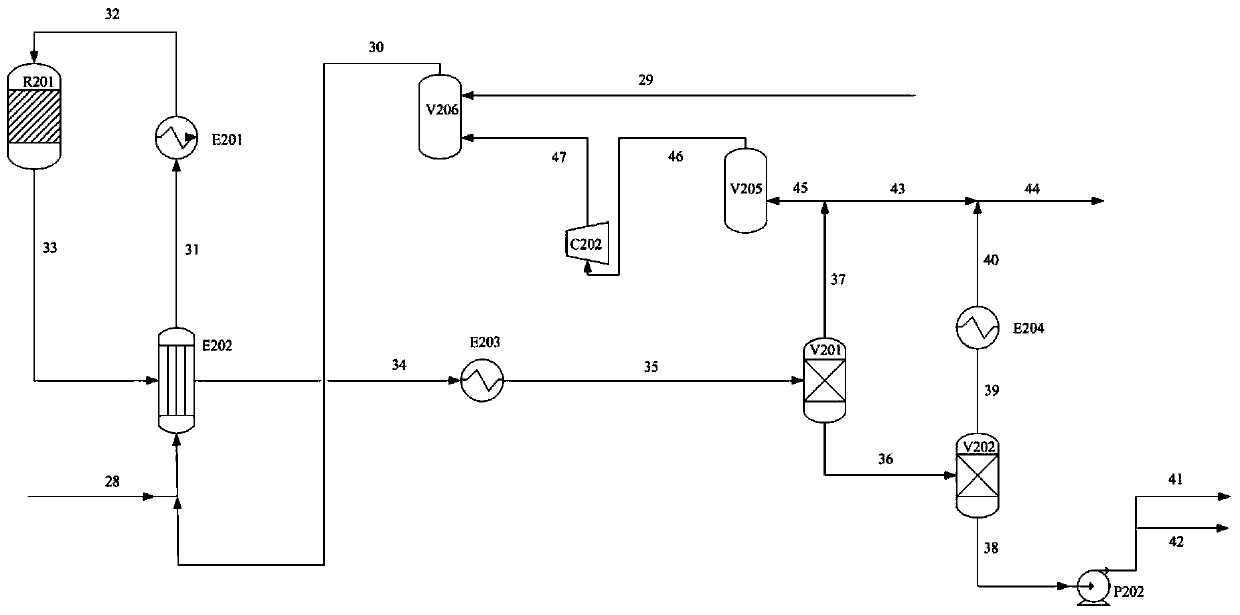

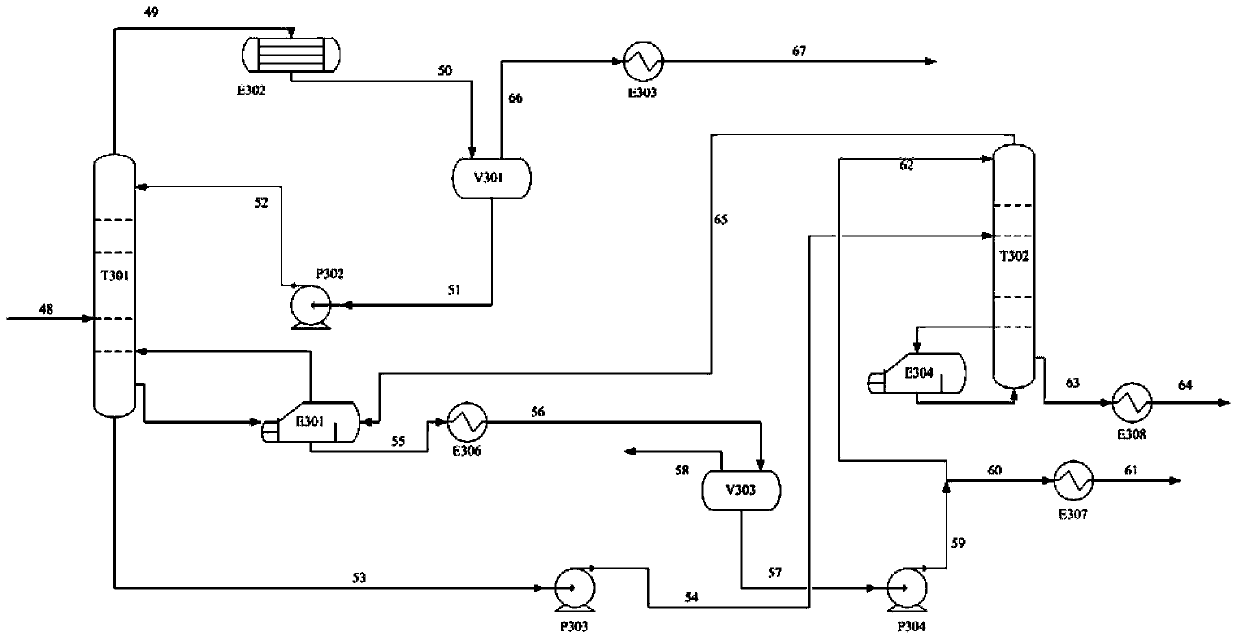

[0026] [embodiment 1] produce ethyl acetate

[0027] If the production of ethyl acetate is the goal, the esterification unit operates at full load, the hydrogenation unit operates at 50% load, and the crude ethanol obtained by hydrogenation can directly go to the esterification tower without separation. At this point the process flow is as follows:

[0028]Stream 1 is ethanol, stream 2 is acetic acid, D6 is an esterification tank, T1 is an esterification tower, the tower still temperature of the esterification tower is 101 ℃, the tower still pressure is 20kPa in terms of gauge pressure, and the temperature in the tower is 75 ℃, The temperature at the top of the column was 71°C. In the reaction kettle of the esterification tower, with 98% concentrated sulfuric acid as a catalyst, ethanol and acetic acid undergo esterification reaction to generate ethyl acetate and water. Stream 3 is ethyl acetate, water and ethanol, which are azeotroped to the top condenser H1 to condense , a...

Embodiment 2

[0034] [Example 2] Production of Industrial Ethanol

[0035] If the goal is to produce industrial ethanol, the crude ester can be directly used as the raw material of the hydrogenation unit without refining. At this point the process flow is as follows:

[0036] Stream 1 is ethanol, stream 2 is acetic acid, D6 is an esterification tank, T1 is an esterification tower, the tower still temperature of the esterification tower is 110 ℃, the tower still pressure is 28kPa in terms of gauge pressure, and the temperature in the tower is 76 ℃, The temperature at the top of the column was 72°C. In the reaction kettle of the esterification tower, with 98% concentrated sulfuric acid as a catalyst, ethanol and acetic acid undergo esterification reaction to generate ethyl acetate and water. Stream 3 is ethyl acetate, water and ethanol, which are azeotroped to the top condenser H1 to condense , after being cooled by the condenser, the stream 4 is obtained, which enters the liquid-liquid sep...

Embodiment 3

[0042] [Example 3] Production of absolute ethanol

[0043] If the production of absolute ethanol is the goal, the crude ester is refined to obtain the refined ester, which is used as the raw material of the hydrogenation unit. At this point the process flow is as follows:

[0044] Stream 1 is ethanol, stream 2 is acetic acid, D6 is an esterification kettle, T1 is an esterification tower, the tower still temperature of esterification tower is 106 ℃, the tower still pressure is 20kPa in gauge pressure, and the temperature in the tower is 74 ℃, The temperature at the top of the column was 70°C. In the reaction kettle of the esterification tower, with 98% concentrated sulfuric acid as a catalyst, ethanol and acetic acid undergo esterification reaction to generate ethyl acetate and water. Stream 3 is ethyl acetate, water and ethanol, which are azeotroped to the top condenser H1 to condense , after being cooled by the condenser, the stream 4 is obtained, which enters the liquid-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com