Method for preparing cyclopentene/cyclohexene-1-boronic acid pinacol ester

A technology of pinacol ester and cyclohexene, which is applied in the field of organic chemical synthesis, can solve the problems of high raw material cost, many impurities, and low yield, and achieve the effects of reduced raw material cost, easy reaction conditions, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

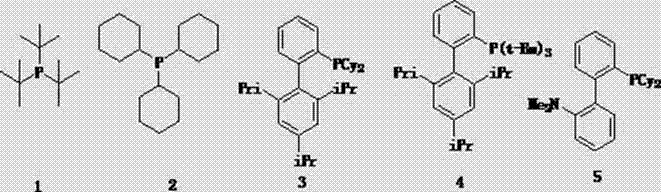

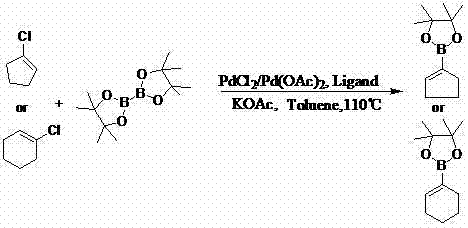

[0023] A method for preparing cyclohexene-1-boronic acid pinacol ester, with PdCl 2 As catalyst, with tricyclohexylphosphine (2) as ligand:

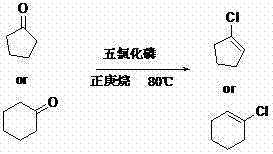

[0024] The preparation of the first step raw material 1-chlorocyclohexene:

[0025] Add 320.30 g (1.556 mol) of phosphorus pentachloride and 800 g of n-heptane into a 2L four-necked flask equipped with a magnetic stirrer, a thermometer, a condenser tube and a tail gas lye absorption device, raise the temperature to 70°C to 74°C, drop Add a mixed solution of 150g (1.533mol) cyclohexanone and 100g n-heptane, drop it for about 2 hours, continue to react for half an hour, after cooling down to 0°C, add 1L of 2mol / L sodium hydroxide solution dropwise, and stir for 1 hour , separated the upper organic layer, dried over anhydrous magnesium sulfate, rectified under reduced pressure, collected the middle distillate at 34-36°C, and obtained 148.09g of 1-chlorocyclohexene, with a GC purity of 97.9% and a yield of 82.2%;

[0026] The preparation o...

Embodiment 2

[0029] A kind of method for preparing cyclopentene-1-boronic acid pinacol ester, with PdCl 2 As a catalyst, with 2-dicyclohexylphosphine-2 , -(N,N-Dimethylamino)biphenyl (5) as ligand:

[0030] The preparation of the first step raw material 1-chlorocyclopentene:

[0031] Add 374.18.30 g (1.818 mol) of phosphorus pentachloride and 803 g of n-heptane into a 2L four-necked flask equipped with a magnetic stirrer, thermometer, condenser and tail gas alkali absorption device, and heat up to 70°C to 74°C , add dropwise a mixed solution of 151.41g (1.803mol) cyclopentanone and 102g n-heptane, drop it in about 2 hours, continue to react for half an hour, after cooling down to 0°C, add dropwise 1L of 2mol / L sodium hydroxide solution, Stir for 1 hour, separate the upper organic layer, dry over anhydrous magnesium sulfate, and distill under reduced pressure to obtain 149.11 g of 1-chlorocyclopentene with a GC purity of 97.2% and a yield of 81.1%;

[0032] The preparation of second step...

Embodiment 3

[0035] A kind of method for preparing cyclopentene-1-boronic acid pinacol ester, with PdCl 2 As a catalyst, with 2-dicyclohexylphosphine-2 , , 4 , ,6 , - Triisopropylbiphenyl (3) as ligand:

[0036] The preparation of the first step raw material 1-chlorocyclopentene:

[0037] Same as step 1 of example 2

[0038] The preparation of second step cyclopentene-1-boronic acid-pinacol ester:

[0039]Add 149.21 g (1.463 mol) of 1-chlorocyclohexene, 2.57 g (0.0146 mol) of palladium chloride, and the ligand ( 3) 10.1g (0.0292mol), double pinacol borate 382.02g (1.504mol), potassium acetate 440.13g (4.49mol), toluene 1L, heated to 110°C, refluxed for 12h, controlled by GC, the reaction ended Finally, the reaction solution was filtered with 10 g of diatomaceous earth as the main filter aid, and the filter cake was discarded. The organic layer was washed twice with 400 mL of water (200×2), and dried with 10 g of anhydrous magnesium sulfate for 4 h. The desiccant was filtered off, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com