Temperature-sensitive antibacterial nanofiber and preparation method thereof

A temperature-sensitive antibacterial, nanofiber technology, applied in the direction of fiber type, fiber treatment, animal fiber, etc., can solve the problems of easy leakage of phase change materials, easy rupture of microcapsules, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

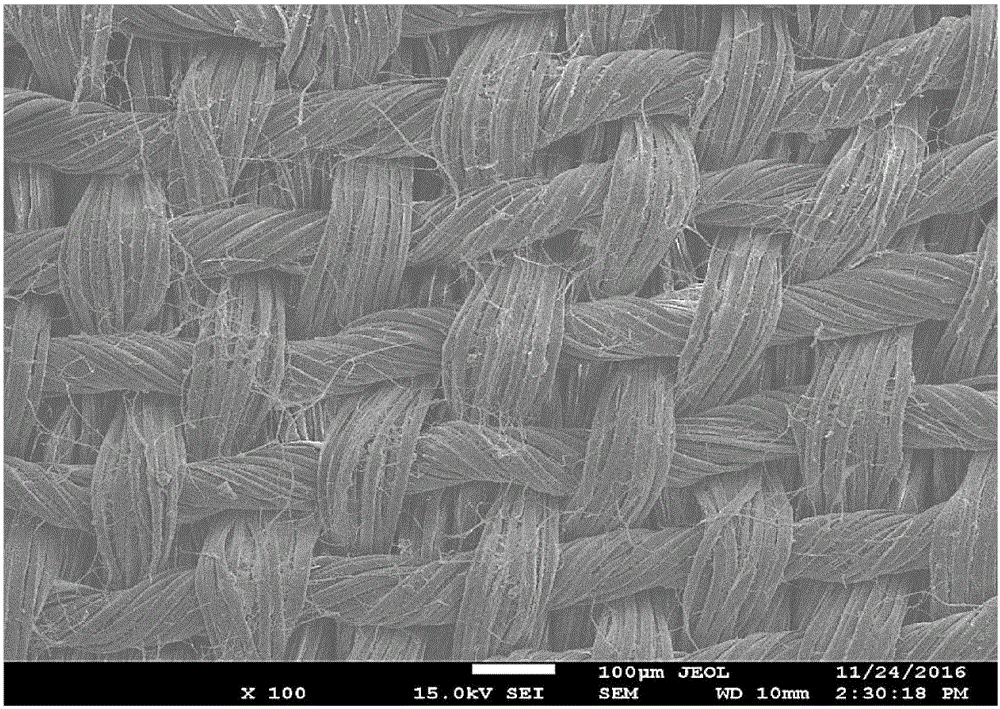

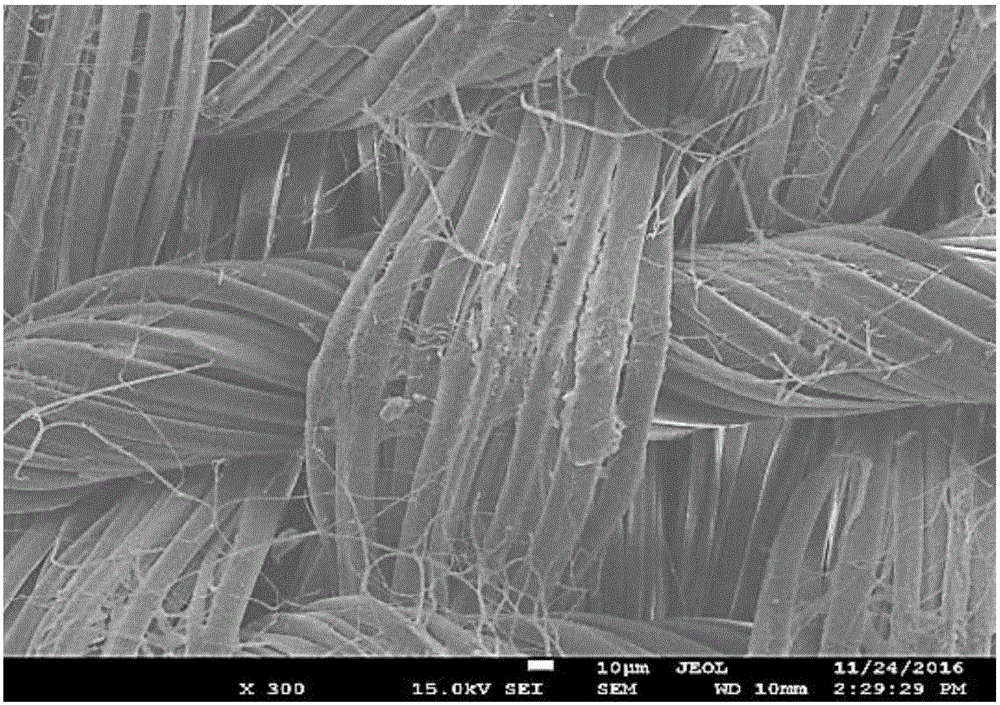

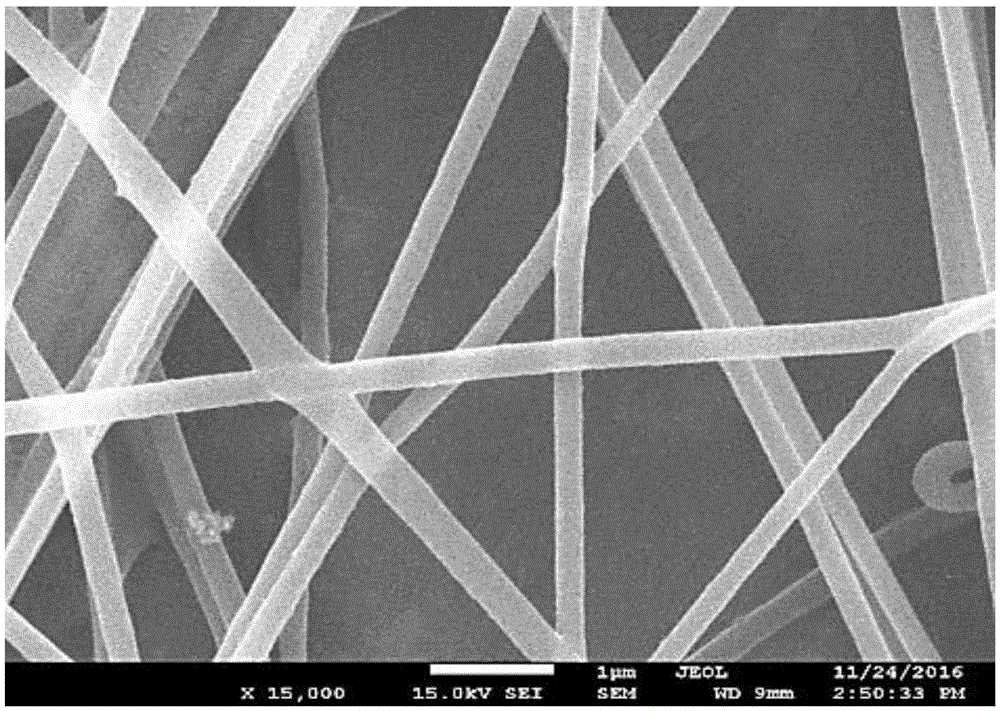

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing temperature-sensitive antibacterial nanofibers, comprising the following steps:

[0026] Add N-isopropylacrylamide, chitosan, N,N-methylenebisacrylamide, initiator and N,N,N,N-tetramethylethylenediamine to acetic acid solution for free radical polymerization Reaction, obtain chitosan / poly N-isopropylacrylamide interpenetrating network hydrogel;

[0027] Mixing the chitosan / poly N-isopropylacrylamide interpenetrating network hydrogel and polyethylene oxide aqueous solution to obtain an electrospinning solution;

[0028] The electrospinning solution is subjected to electrospinning to obtain temperature-sensitive antibacterial nanofibers.

[0029] In the present invention, N-isopropylacrylamide, chitosan, N,N-methylenebisacrylamide, initiator and N,N,N,N-tetramethylethylenediamine are added to acetic acid solution for free Based polymerization reaction, chitosan / poly N-isopropylacrylamide interpenetrating network hydrogel was...

Embodiment 1

[0040] (1) Under normal temperature conditions, add 4g of N-isopropylacrylamide into 50mL of acetic acid solution with a mass concentration of 2%, and stir continuously. During the stirring process, add 1g of chitosan, 0.15g of N,N- Methylenebisacrylamide, after stirring for 5 minutes, stop stirring, continue to add 0.1g ammonium persulfate and 1mL N,N,N,N-tetramethylethylenediamine to the mixed solution, stir at room temperature until completely dissolved, and prepare Chitosan / poly-N-isopropylacrylamide interpenetrating network hydrogel.

[0041] (2) Add polyethylene oxide (relative molecular mass 40kDa) into 180mL deionized water, heat at 60°C and stir for 4h to prepare a polyethylene oxide aqueous solution containing polyethylene oxide with a concentration of 10g / mL .

[0042] (3) Mix chitosan / poly N-isopropylacrylamide interpenetrating network hydrogel with polyethylene oxide aqueous solution at a volume ratio of 5 / 1, stir at room temperature until uniform, and prepare ch...

Embodiment 2

[0048] (1) Under normal temperature conditions, add 8g of N-isopropylacrylamide into 150mL of acetic acid solution with a mass concentration of 5%, and stir continuously. During the stirring process, add 6g of chitosan, 0.5g of N,N- Methylenebisacrylamide, after stirring for 10 minutes, stop stirring, continue to add 0.5g potassium persulfate and 3mL N,N,N,N-tetramethylethylenediamine to the mixed solution, stir at room temperature until completely dissolved, and prepare Chitosan / poly-N-isopropylacrylamide interpenetrating network hydrogel.

[0049] (2) Add polyethylene oxide (relative molecular mass 40kDa) into 180mL deionized water, heat at 60°C and stir for 4h to prepare a polyethylene oxide aqueous solution containing polyethylene oxide with a concentration of 10g / mL .

[0050] (3) Mix chitosan / poly-N-isopropylacrylamide interpenetrating network hydrogel with polyethylene oxide aqueous solution at a volume ratio of 3 / 1, stir at room temperature until uniform, and prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com