Acetic acid production process

a technology of acetic acid and production process, which is applied in the direction of optical radiation measurement, physical/chemical process catalysts, instruments, etc., can solve the problems of large amount of water (about 14%), increased hydrogen iodide amount, and engineering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

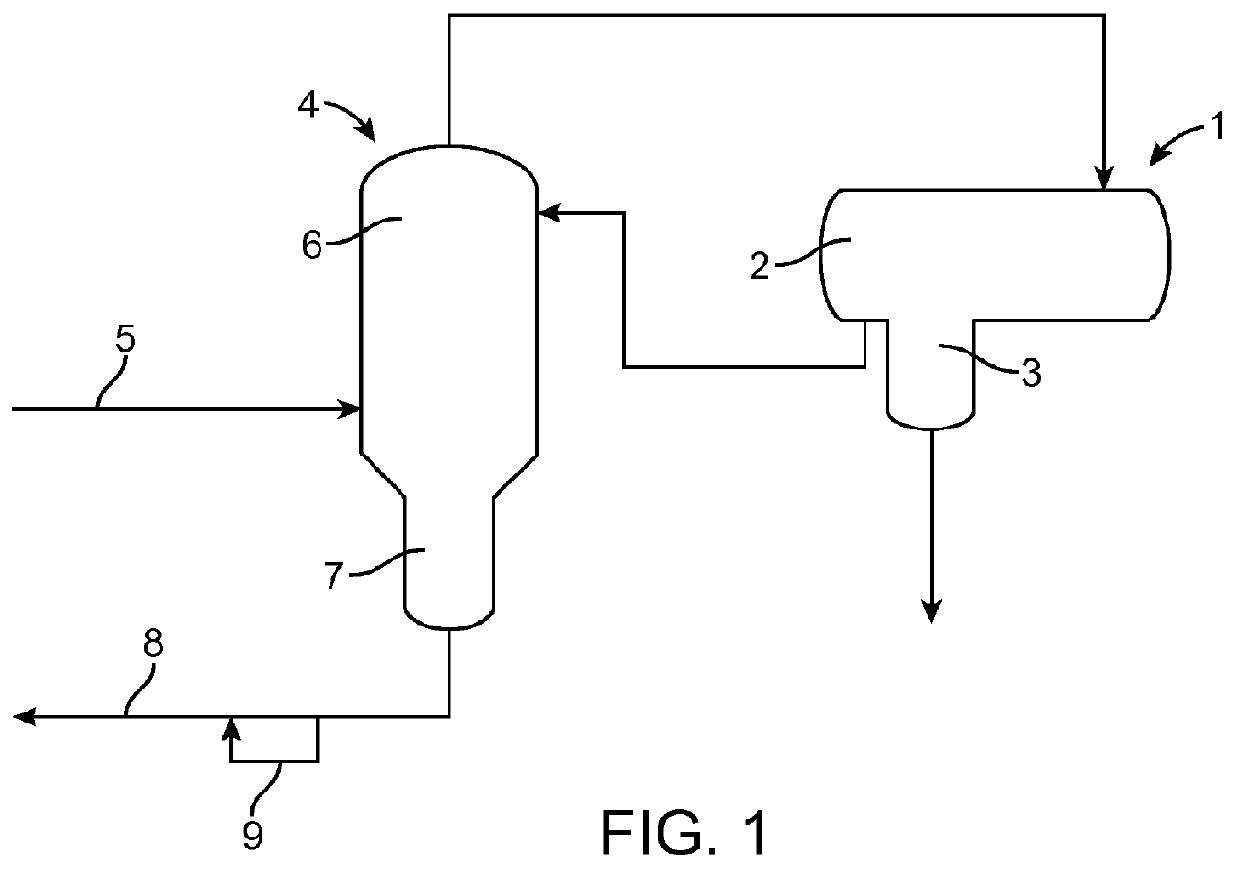

Image

Examples

examples

Methods

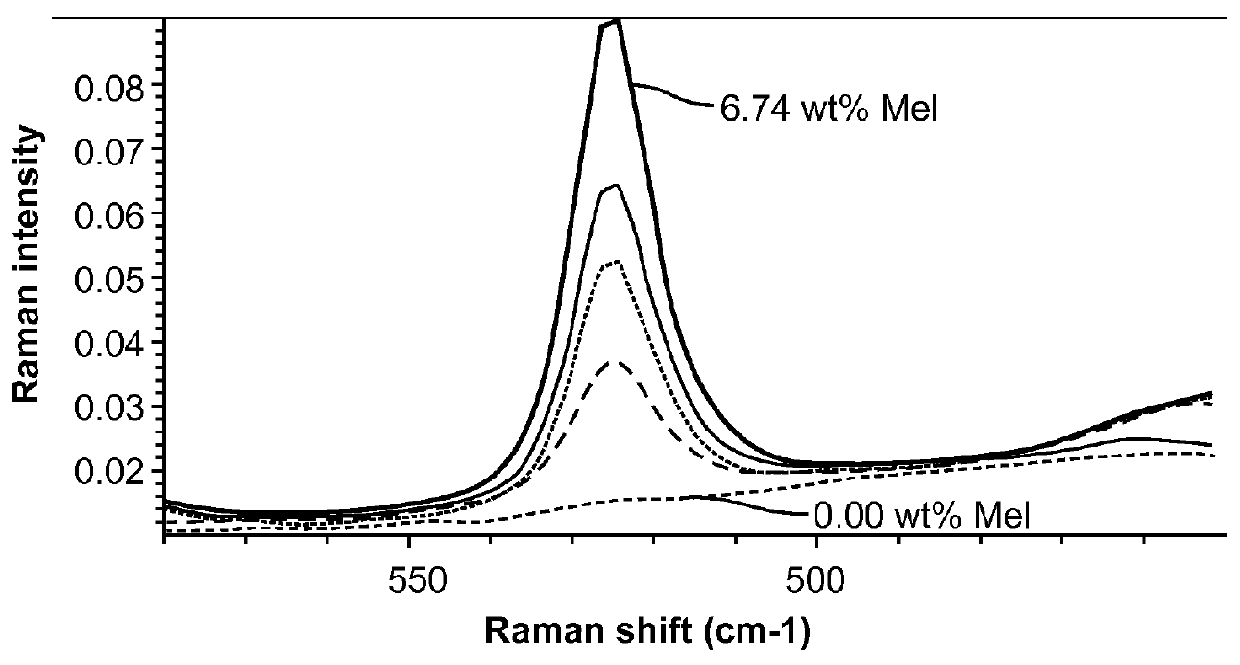

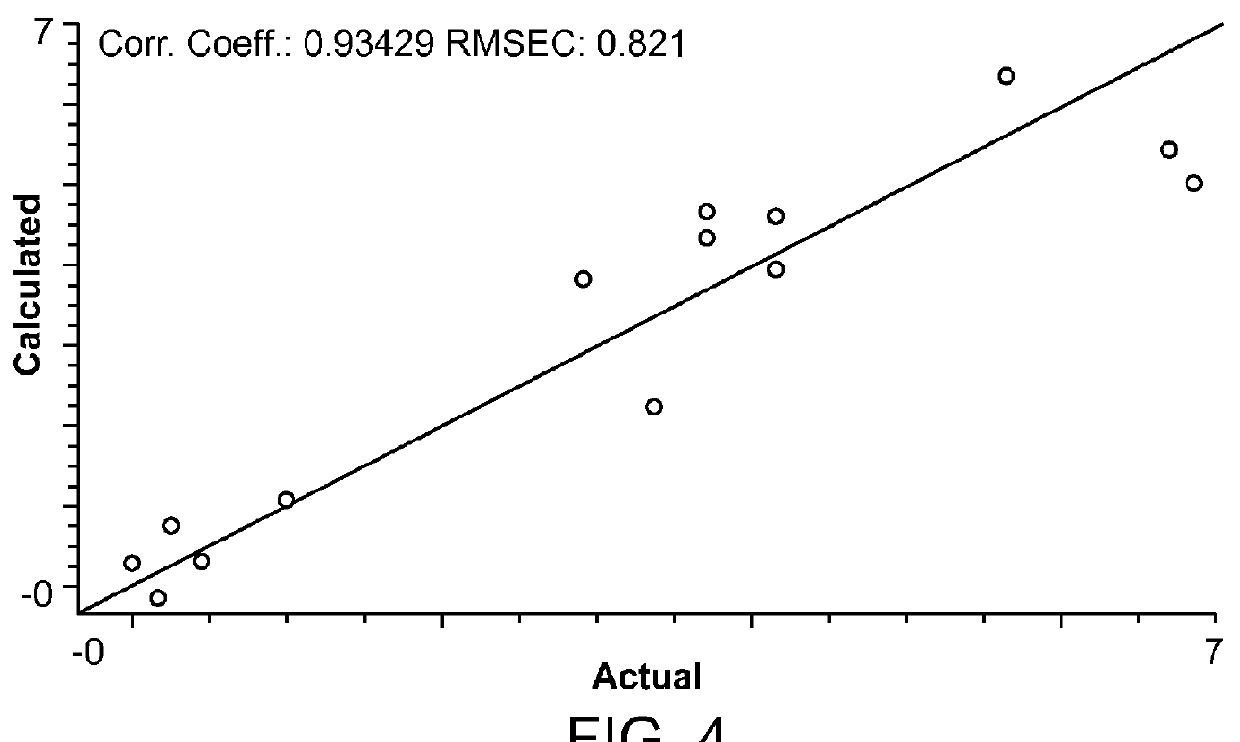

[0055]To identify the Raman shifts and intensities of components a number of experiments are performed (approximately 10-20 standards) for each sample type in which the concentration of said component varies while the concentrations of other components remain essentially constant or under such conditions that the other components will not interfere with the measurement of said component. These experiments are performed by preparation of multi-component standards in 20 mL sample vials at room temperature and atmospheric pressure.

[0056]It should be noted that the appropriate Raman shift region used for quantitatively analyzing a particular component may vary depending on the vessel or stream in which it is being analyzed, given that a particular component may be more concentrated in one location in the process as compared to its concentration at another location and that a particular component's Raman peak will be interfered with to varying degrees depending on the sample type....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com