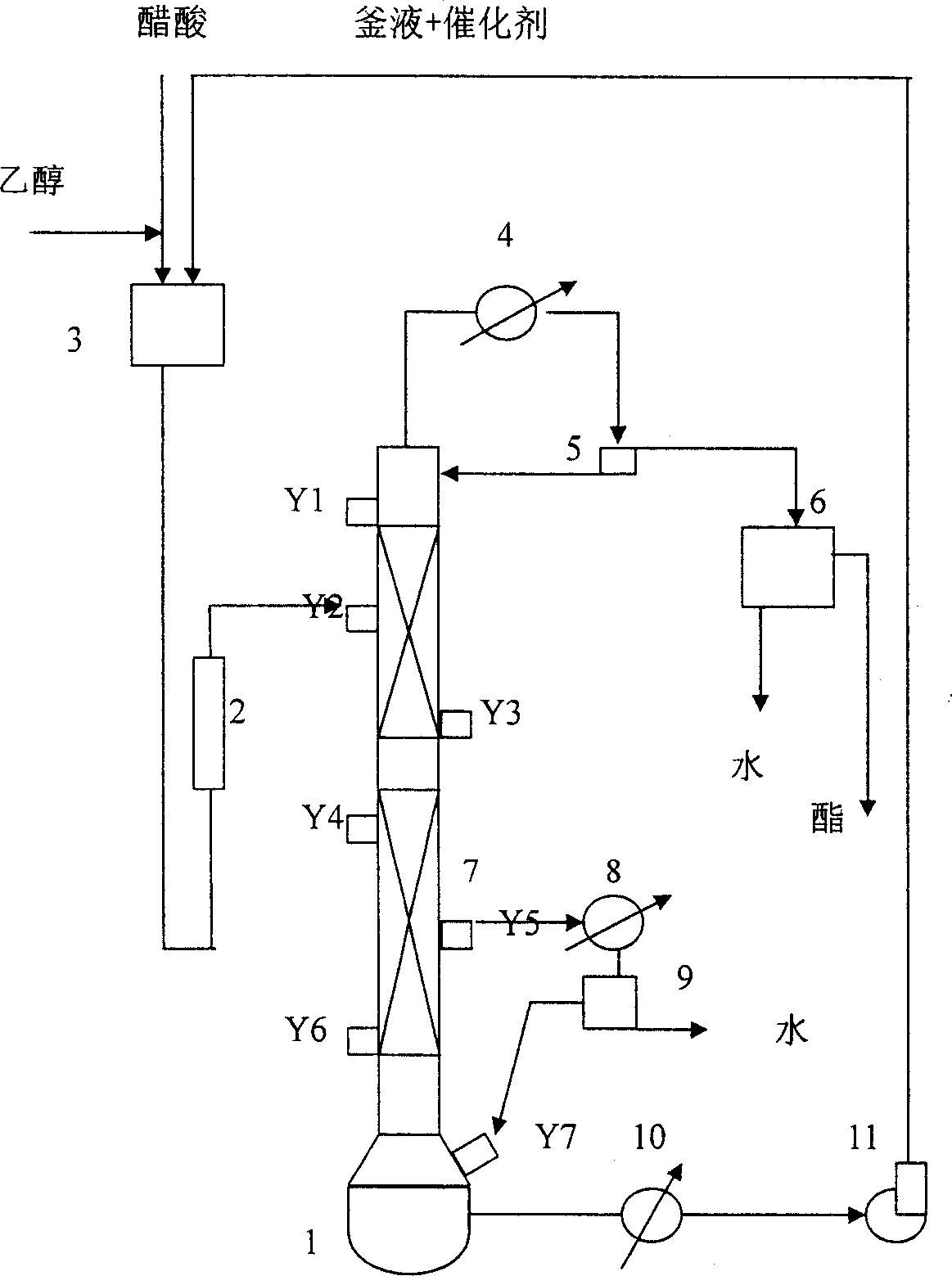

Method and apparatus for continuously preparing ethyl acetate by single tower

A technology of ethyl acetate and strong acid, which is applied in the field of preparation of ethyl acetate, can solve problems such as dilute acid treatment of tower still liquid, and achieve the effects of improving single-pass conversion rate, improving utilization rate, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1). First add the acid-alcohol mixture with an acid-alcohol ratio of 5:1 (mol ratio) in the tower kettle, add 5% concentrated sulfuric acid by acetic acid quality and 10-50ml butanol water-carrying agent.

[0042] (2). Heat the solution in the tower kettle until it boils. When the steam reaches the top of the tower, turn off the condensed water and keep the total reflux operation. After the temperature at the top of the tower is stable, adjust the reflux ratio, and at the same time feed the mixed material with an acid-alcohol ratio of 1:1 (mol ratio) and concentrated sulfuric acid from the upper part of the tower, and adjust a certain reflux ratio with a reflux ratio device to make the reaction The crude ester product produced is taken out from the top of the tower, and the temperature at the top of the tower is kept constant. At the same time, the gas phase is discharged from the lower part of the tower, and enters the phase separator to separate water through condens...

Embodiment 2

[0051] ((1). Adding the acid-alcohol mixture that the acid-alcohol ratio is 10:1 (mol ratio) in the tower kettle earlier, adding quality is acetic acid 10% vitriol oil and 15-45ml butyl acetate water-carrying agent.

[0052] (2). Heat the solution in the tower kettle until it boils. When the steam reaches the top of the tower, turn off the condensed water and keep the total reflux operation. After the temperature at the top of the tower is stabilized, the acid-alcohol ratio is 1:1 (mol ratio) and the mixed material containing concentrated sulfuric acid is fed from the upper part of the tower, and a certain reflux ratio is adjusted with a reflux ratio device to make the crude ester product produced by the reaction Take it out from the top of the tower, and keep the temperature at the top of the tower constant. At the same time, the gas phase is discharged from the lower part of the tower, and enters the phase separator to separate water through condensation, and the organic pha...

Embodiment 3

[0063] (1). Earlier in the present embodiment, take about 80% acid aqueous solution as raw material, and the following acid-alcohol proportioning ratio is the value converted into pure acetic acid.

[0064] (2). Adding the acid-alcohol mixture that the acid-alcohol ratio is 2: 1 (mol ratio) in the tower kettle, adding the powdery strong acid ion exchange resin catalyst and 10-40ml butyl acetate belt that the quality is acetic acid 12% Aqua.

[0065] (3). Heat the solution in the tower kettle until it boils. When the steam reaches the top of the tower, turn off the condensed water and keep the total reflux operation. After the temperature at the top of the tower is stabilized, the acid-alcohol ratio is 1:1 (mol ratio) and the mixed material containing concentrated sulfuric acid is fed from the upper part of the tower, and a certain reflux ratio is adjusted with a reflux ratio device to make the crude ester product produced by the reaction Take it out from the top of the tower,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com