Preparation method of carbon carrying cobalt prophyrin oxygen reduction catalyst

A carbon-supported cobalt porphyrin oxygen and catalyst technology, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of general catalyst performance, long time, complicated process, etc., shorten the preparation time, improve Activity, the effect of simplifying the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

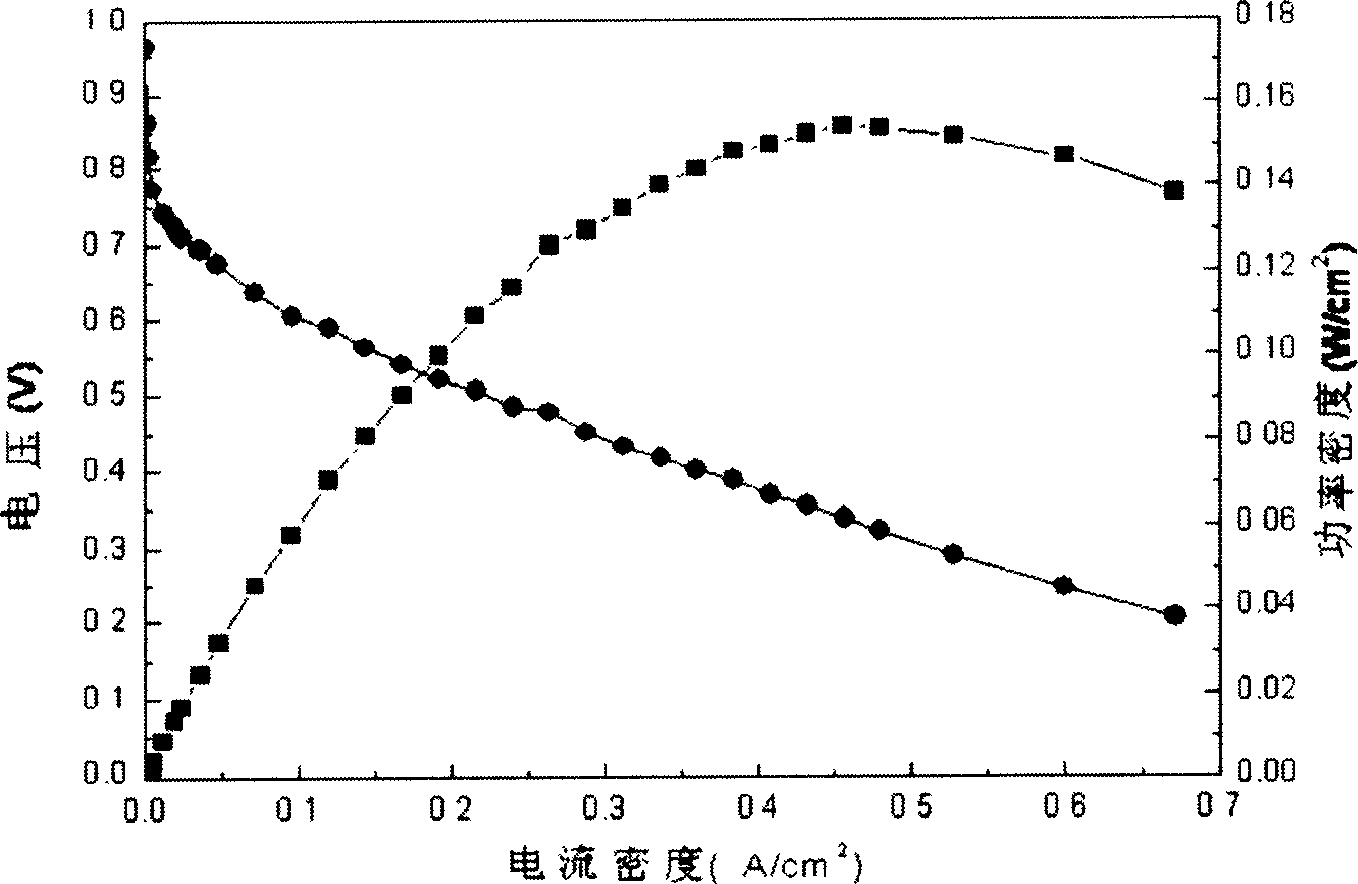

Embodiment 1

[0019] Embodiment 1: (1) carry out high-energy ball milling after the VulcanXC-72R carbon black of 5g Cabot Company is fully dried, then with 100ml 6M HNO 3 Reflux at 60° C. for 4 hours for pretreatment, wash and dry in a vacuum oven at 110° C. to obtain 4.9 g of pretreated carbon black.

[0020] (2) Put 0.25g of tetramethylphenylporphyrin (TPP), 0.1755g of cobalt acetate and 0.5g of pretreated carbon black in 25ml of glacial acetic acid, mix them uniformly in ultrasonic for 15min, and then place In a microwave oven with a condensing tube, reflux at a power of 130W for 90min, cool down, add 30ml of methanol to precipitate, stand still, filter, wash with methanol until the filtrate is colorless, and dry the filter cake in a vacuum oven at 60°C for 12h to obtain 0.71g of catalyst Precursor.

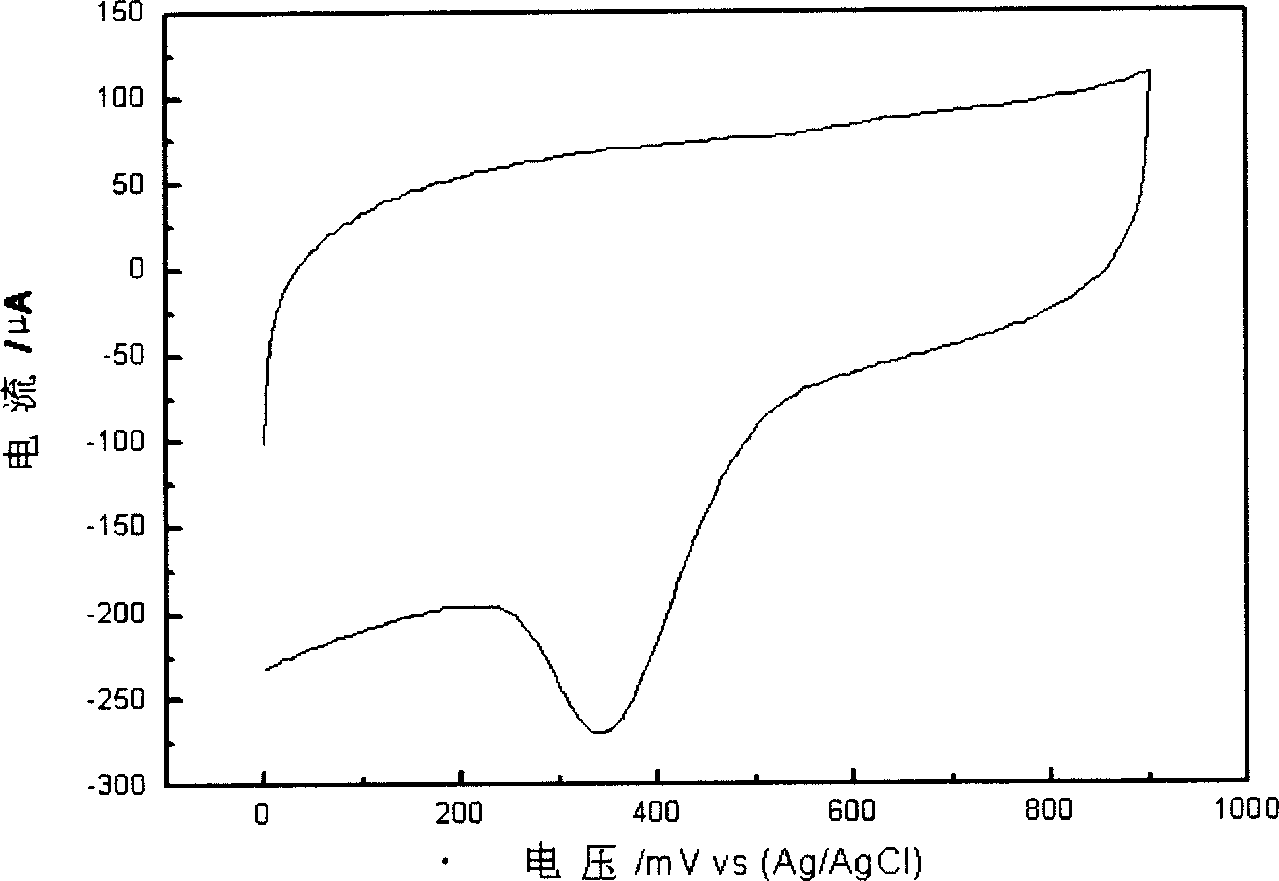

[0021] (3) 0.2g of the catalyst precursor was heat-treated at 900°C for 2h under the protection of argon, cooled naturally, and ground to obtain 0.195g of carbon-supported cobalt porphyrin...

Embodiment 2

[0023] Embodiment 2: (1) carry out high-energy ball milling after the Black Pearl2000 carbon black of 5g Cabot company is fully dried, then with 30wt%H 2 o 2 Soak at room temperature for 4 hours for pretreatment, after washing, put it into a vacuum oven and dry at 110° C. to obtain 4.8 g of pretreated carbon black.

[0024] (2) Add 0.25g of tetramethoxyphenylporphyrin (TMPP), 0.1755g of cobalt acetate and 0.5g of pretreated carbon black to 25ml of glacial acetic acid, mix uniformly in ultrasonic for 15min, and then place in a In the microwave oven of the reflux condenser, the reaction was refluxed for 150 minutes with a power of 130W. Cool, add 30ml of methanol to precipitate, let stand, filter, wash with methanol until the filtrate is colorless, and dry the filter cake in a vacuum oven at 60°C for 12h to obtain 0.72g of catalyst precursor.

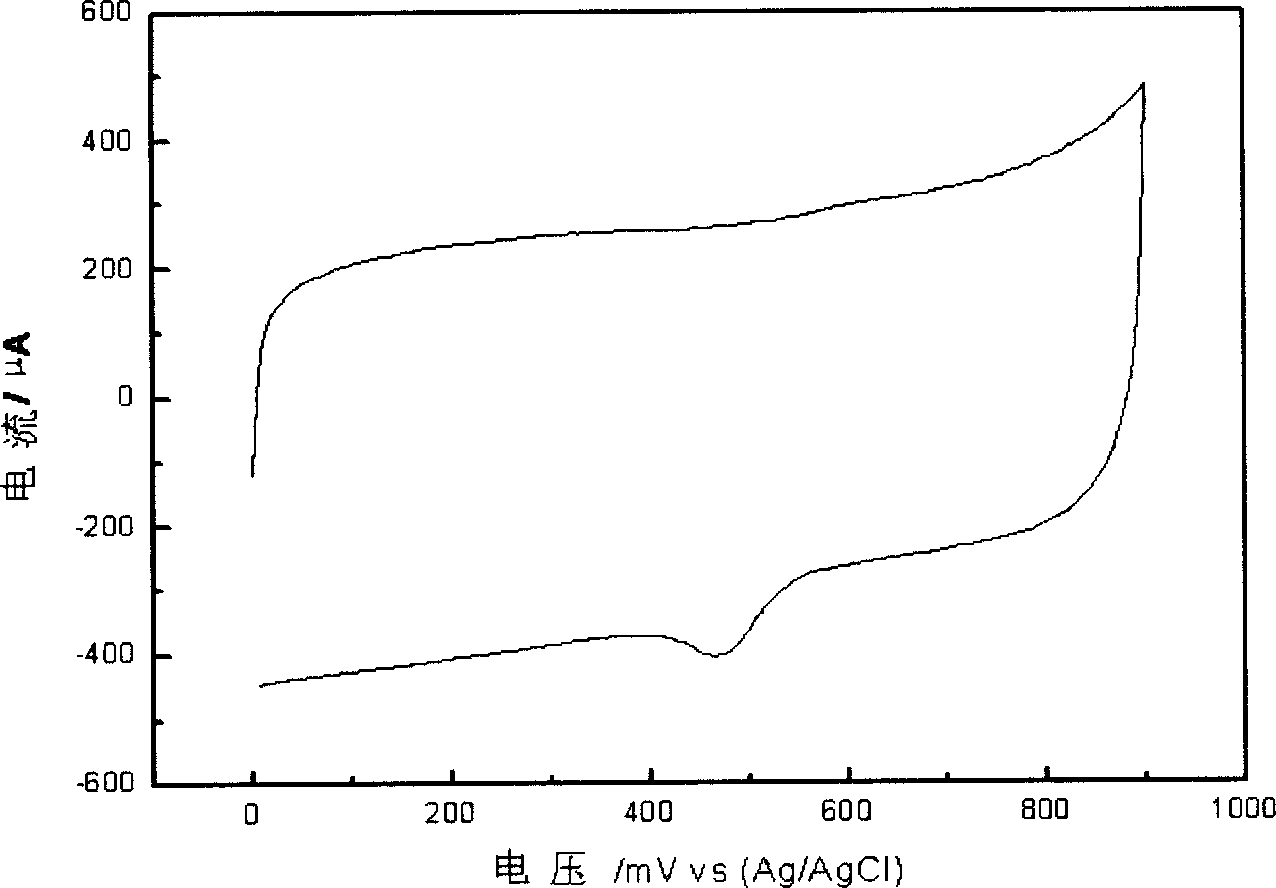

[0025] (3) 0.2g of the catalyst precursor was heat-treated at 900°C for 2h under argon protection, cooled naturally, and ground to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com