Organic thermoelectric material based on cuprous vinyl tetramercaptan and preparation method thereof

A technology of ethylene tetrathiol and thermoelectric materials, which can be used in thiol preparation, thermoelectric device node lead-out materials, organic chemistry, etc., can solve problems such as low thermal conductivity, and achieve low cost, short process flow, and excellent thermoelectricity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

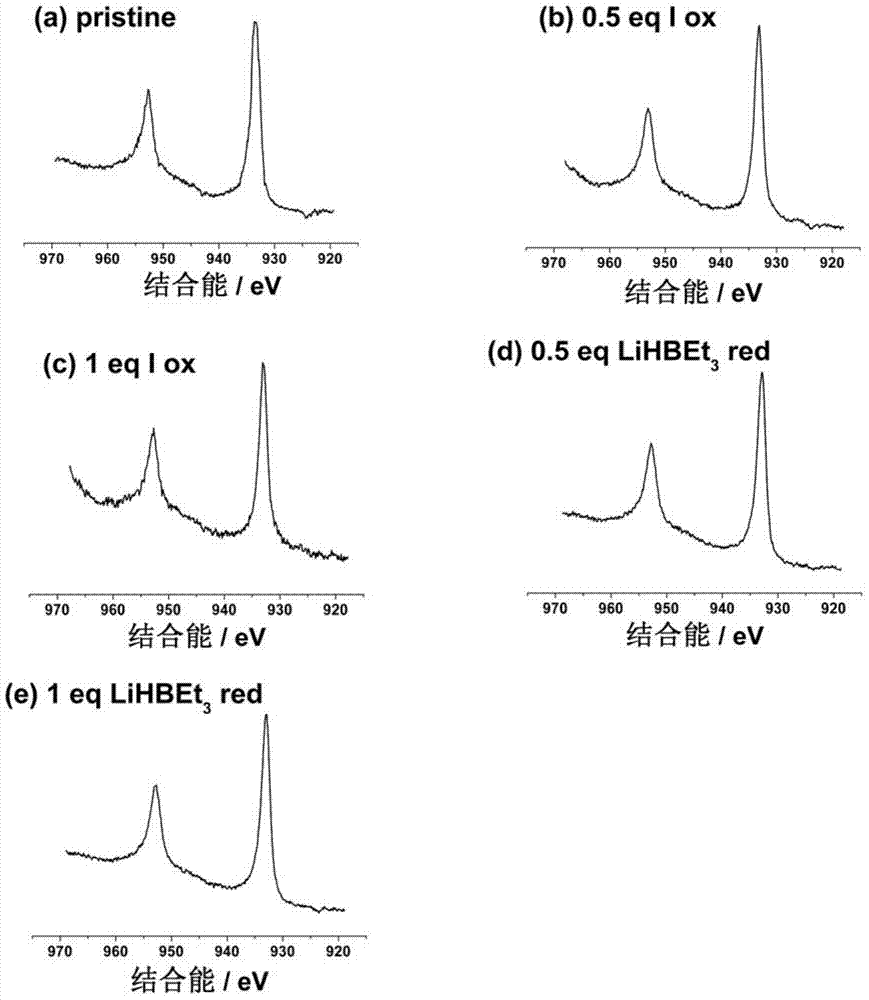

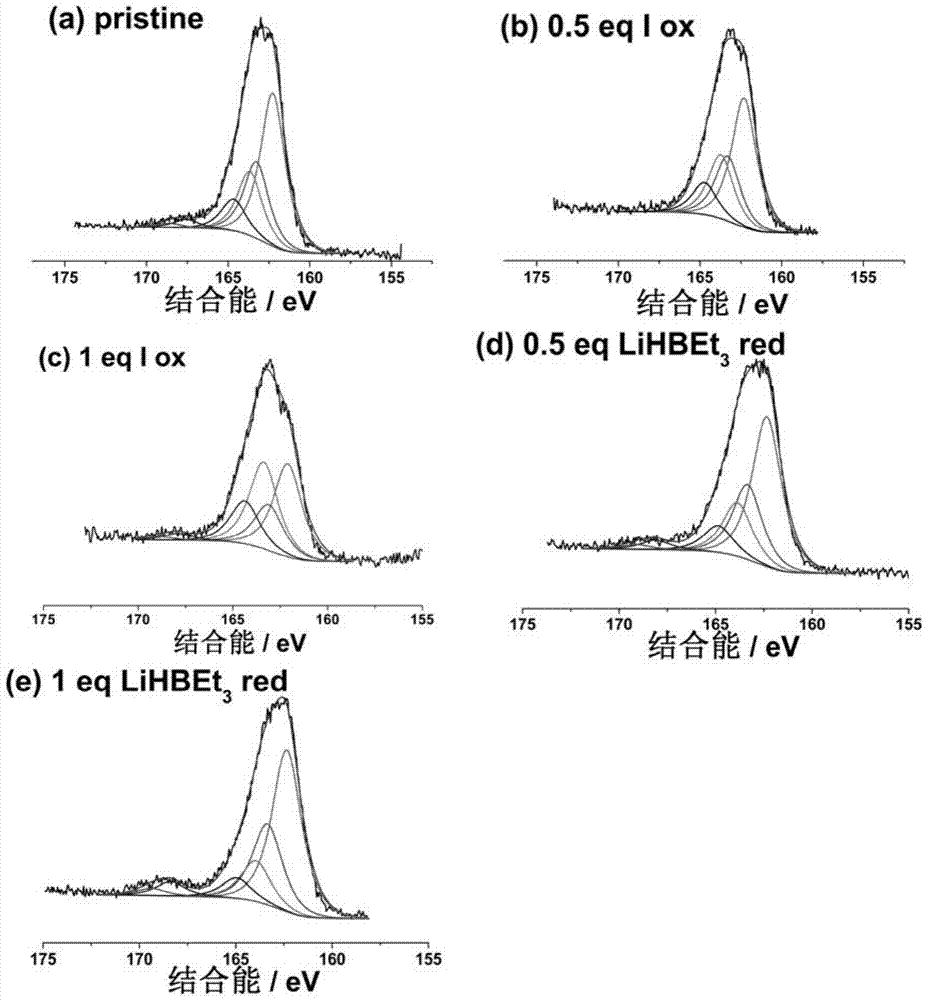

[0032] The preparation of ethylene tetrathiol cuprous oxide shown in embodiment 1, formula I

[0033] In an argon atmosphere, disperse 1g of 1,3,4,6-tetrathiacyclopentene-2,5-dione in methanol, add 2.07g of sodium methoxide, and reflux for 12h; then add 3.66g of cuprous iodide , reflux for 12 hours; filter, wash the obtained solid with water, methanol and ether in sequence, and dry it in a vacuum oven (absolute pressure: 0.06Pa) at 50°C to obtain cuprous ethylene tetrathiol represented by formula I, which is marked as pristine.

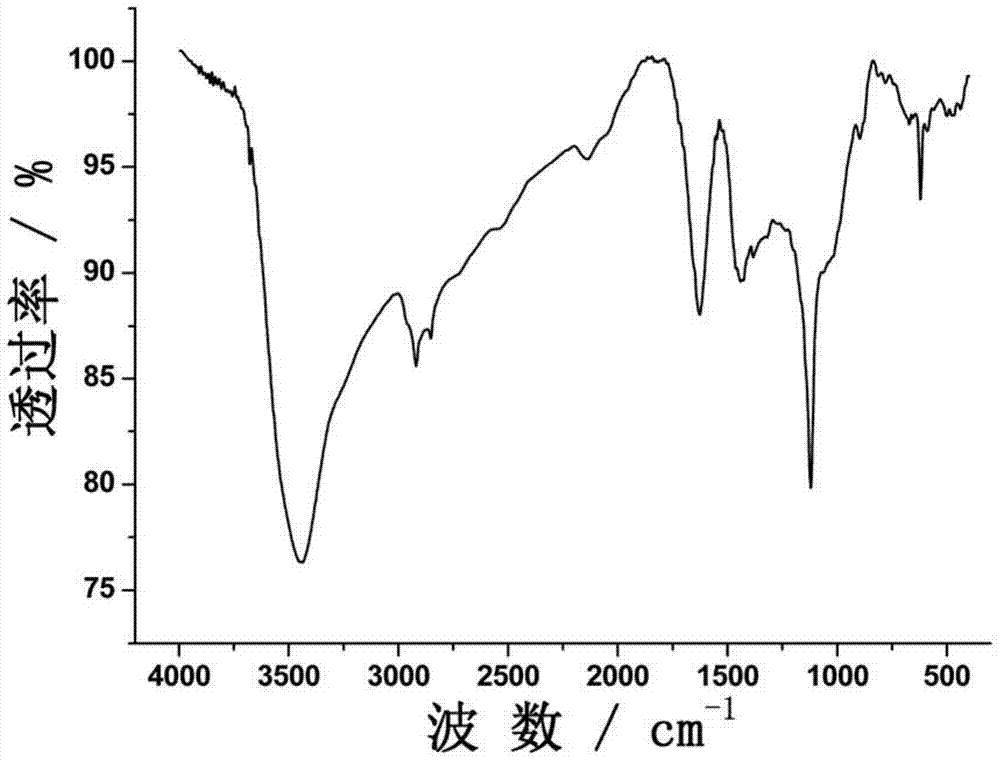

[0034] Infrared spectrum: 1441cm -1 (ν(C=C)); 1121cm -1 , 897cm -1 , 621cm -1 (ν(C-S)); 470cm -1 (ν(S 2 C=CS 2 )),Such as figure 1 As shown, the identified structure is correct.

Embodiment 2、I2

[0035] Embodiment 2, I 2 Preparation of Organic Thermoelectric Materials by Oxidation

[0036] The compound prepared in Example 1 was dispersed in methanol, and 305mg I was added 2 , reacted at 20°C for 12h, filtered, washed with methanol, water, methanol and ether in turn; dried at 50°C in a vacuum oven (absolute pressure 0.06Pa) to obtain an organic thermoelectric material, and marked as 0.5eq I ox .

Embodiment 3、I2

[0037] Embodiment 3, I 2 Preparation of Organic Thermoelectric Materials by Oxidation

[0038] The compound prepared in Example 1 was dispersed in methanol, and 609mg I was added 2, reacted at 40°C for 18h, filtered, washed with methanol, water, methanol and ether in turn; dried in a vacuum oven (absolute pressure 0.06Pa) at 50°C to obtain an organic thermoelectric material, which was labeled as 1eq I ox.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com