Preparation method of large-particle narrow-distribution aluminum doped tricobalt tetroxide

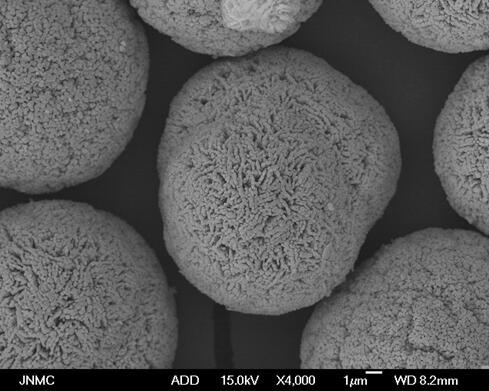

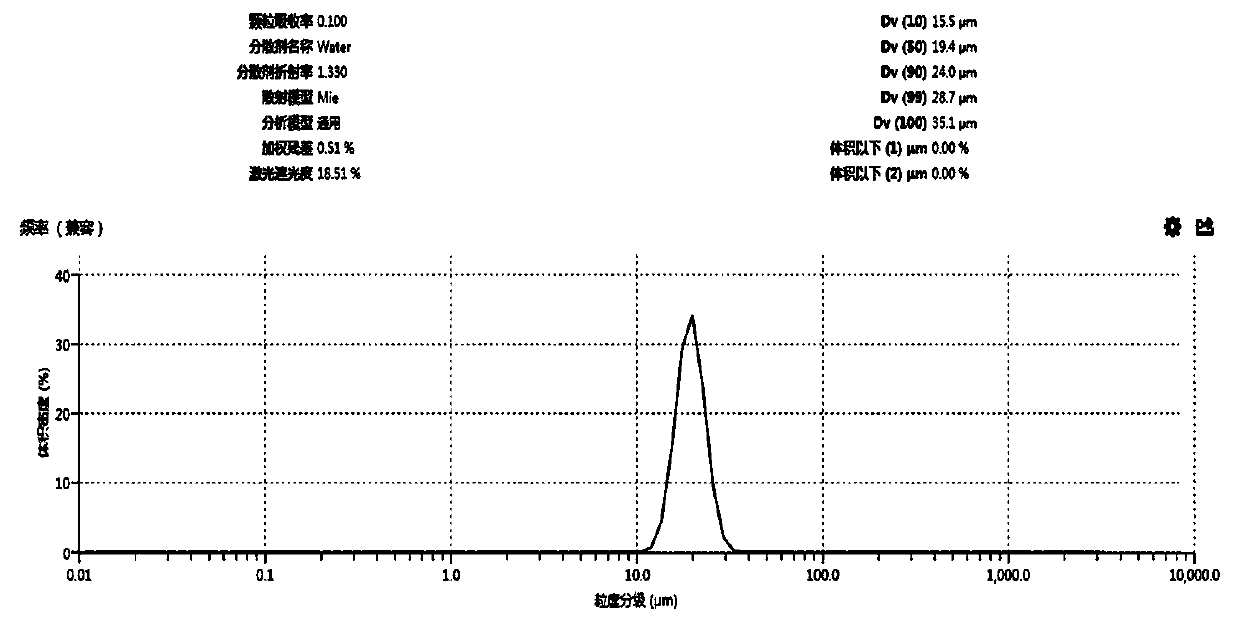

A technology of cobalt tetroxide with narrow distribution, applied in cobalt oxide/cobalt hydroxide, electrical components, battery electrodes, etc., can solve the problems of affecting the structural stability of lithium cobalt oxide, uneven distribution of aluminum elements, affecting the uniformity of aluminum elements, etc. To achieve the effect of complete crystal form, uniform distribution of aluminum elements, and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing aluminum-doped tricobalt tetroxide with narrow distribution of large particles, comprising a continuous synthesis stage of cobalt doped with aluminum-cobalt carbonate with narrow distribution of large particles and a calcination stage of cobalt doped with aluminum-cobalt carbonate with narrow distribution of large particles;

[0026] The continuous synthesis stage of the described large particle narrow distribution doped aluminum cobalt carbonate comprises the following steps:

[0027] a, nuclear growth process: cobalt metal ion concentration is 110g / L cobalt chloride metal solution with the flow rate of 350L / h, aluminum metal ion concentration is the aluminum chloride metal solution of 3.8g / L with the flow rate of 35L / h and Concentration is that the ammonium bicarbonate solution of 240g / L is with the flow rate of 450L / h, and flow joins and has concentration and is that 20g / L ammonium bicarbonate solution is the crystal nucleation generating kettle...

Embodiment 2

[0039] A method for preparing aluminum-doped tricobalt tetroxide with narrow distribution of large particles, comprising a continuous synthesis stage of cobalt doped with aluminum-cobalt carbonate with narrow distribution of large particles and a calcination stage of cobalt doped with aluminum-cobalt carbonate with narrow distribution of large particles;

[0040] The continuous synthesis stage of the described large particle narrow distribution doped aluminum cobalt carbonate comprises the following steps:

[0041] a, nuclear growth process: the cobalt metal ion concentration is the cobalt sulfate metal liquid of 90g / L with the flow rate of 450L / h, the aluminum sulfate metal liquid with the aluminum metal ion concentration of 8.4g / L with the flow rate and the concentration of 45L / h as 200g / L ammonium bicarbonate solution is added to the crystal nucleation kettle with a concentration of 40g / L ammonium bicarbonate solution as the bottom liquid at a flow rate of 550L / h to carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com