Method for preparing large-particle spherical narrow-distribution tricobalt tetroxide used for high-voltage lithium cobaltate

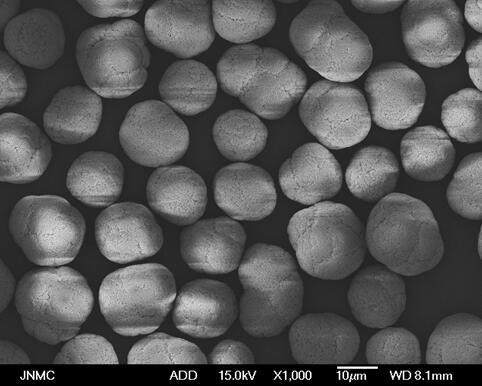

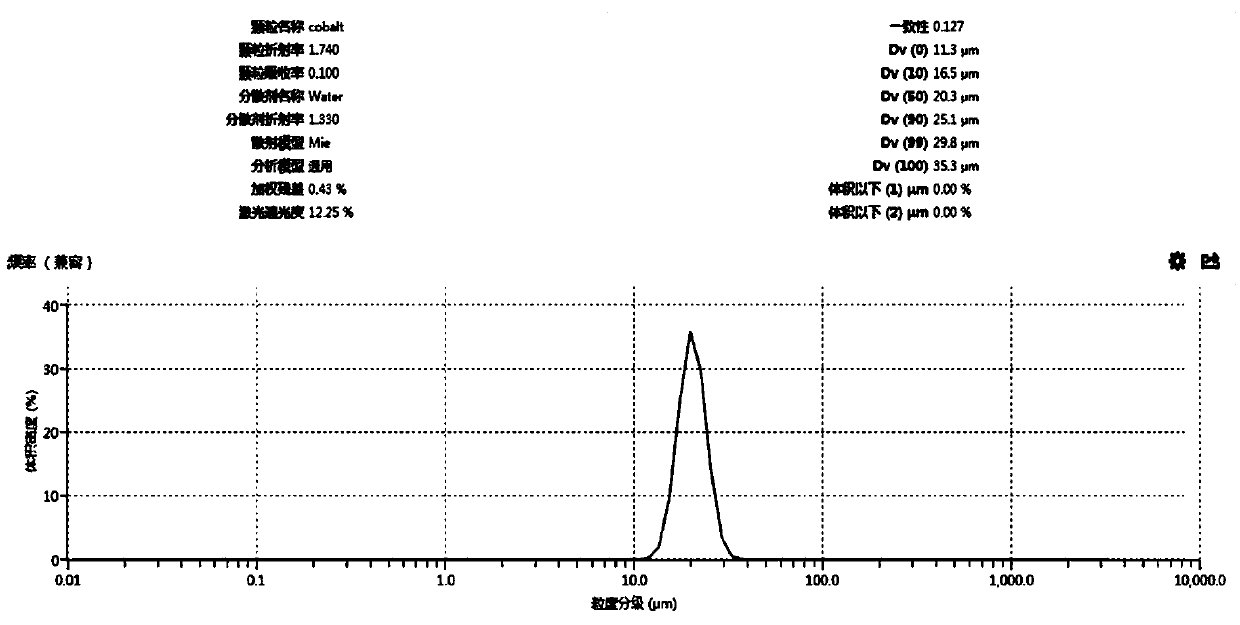

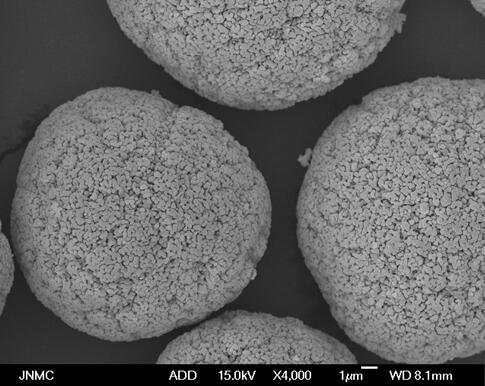

A technology of cobalt trioxide and large particles, which is applied in the field of lithium-ion batteries, can solve the problems of narrow particle size distribution, low tap density, poor stability, etc., and achieve the effects of narrow particle size distribution, complete crystal form and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of large-particle spherical narrow-distribution cobalt tetroxide for high-voltage lithium cobaltate, comprising a continuous production stage of large-particle spherical narrow-distribution cobalt carbonate and a large-particle spherical narrow-distribution cobalt carbonate calcination stage;

[0025] The continuous production stage of the large particle spherical narrow distribution cobalt carbonate comprises the following steps:

[0026] a, nucleation growth process: add concentration 240g / L ammonium bicarbonate bottom liquid in the crystal nucleation kettle, the cobalt chloride solution of total metal ion concentration 110g / L with the flow rate of 350L / h and the ammonium bicarbonate of concentration 240g / L The solution is fed into the crystal nucleation tank at a flow rate of 150-1000L / h in parallel for nucleation reaction, the pH value is controlled at 6.8-8.5, the reaction time is 3.5h, and the nucleus grows to a median diameter of 8.5 microns; ...

Embodiment 2

[0037] The continuous production stage of the large particle spherical narrow distribution cobalt carbonate comprises the following steps:

[0038] a, nucleation growth process: add concentration 200g / L ammonium bicarbonate bottom liquid in the crystal nucleation kettle, the cobalt sulfate solution of total metal ion concentration 90g / L with the flow rate of 450L / h and the ammonium bicarbonate solution of concentration 200g / L The flow rate of 150-1000L / h is fed into the crystal nucleation tank for nucleation reaction, the pH value is controlled at 6.8-8.5, the reaction time is 3 hours, and the nucleus grows to a median diameter of 9.4 microns;

[0039] b. Particle primary growth process: add the ammonium bicarbonate base solution with a concentration of 200g / L in the primary reaction kettle, add the slurry in the crystal nucleation kettle to the primary reaction kettle, open the stirring device, and at the same time, the total metal ion concentration The cobalt sulfate solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com