Method for synthesizing new hesperidin through high-flux enzyme process

A technology for neohesperidin and enzymatic synthesis, which is applied in the field of high-throughput enzymatic synthesis of neohesperidin, can solve the problems of environmental pollution and limited sources of discarded orange peels, and achieves no environmental pollution and wide source of raw materials. , the effect of saving purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

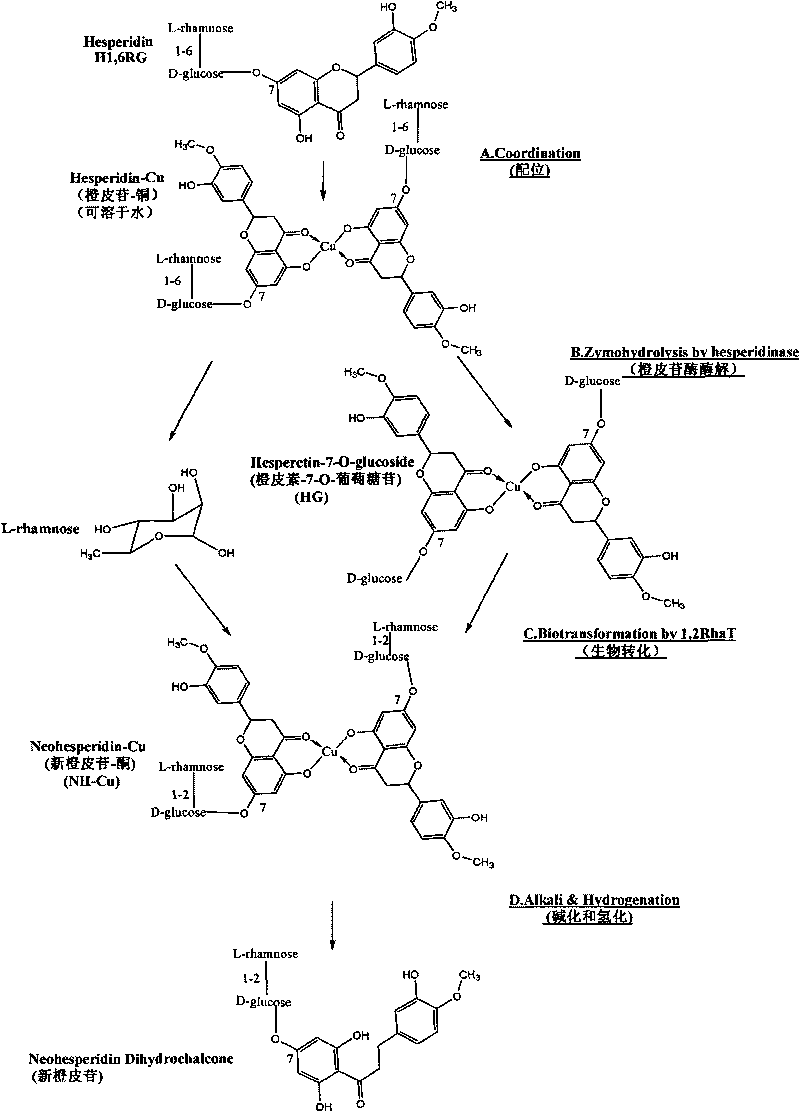

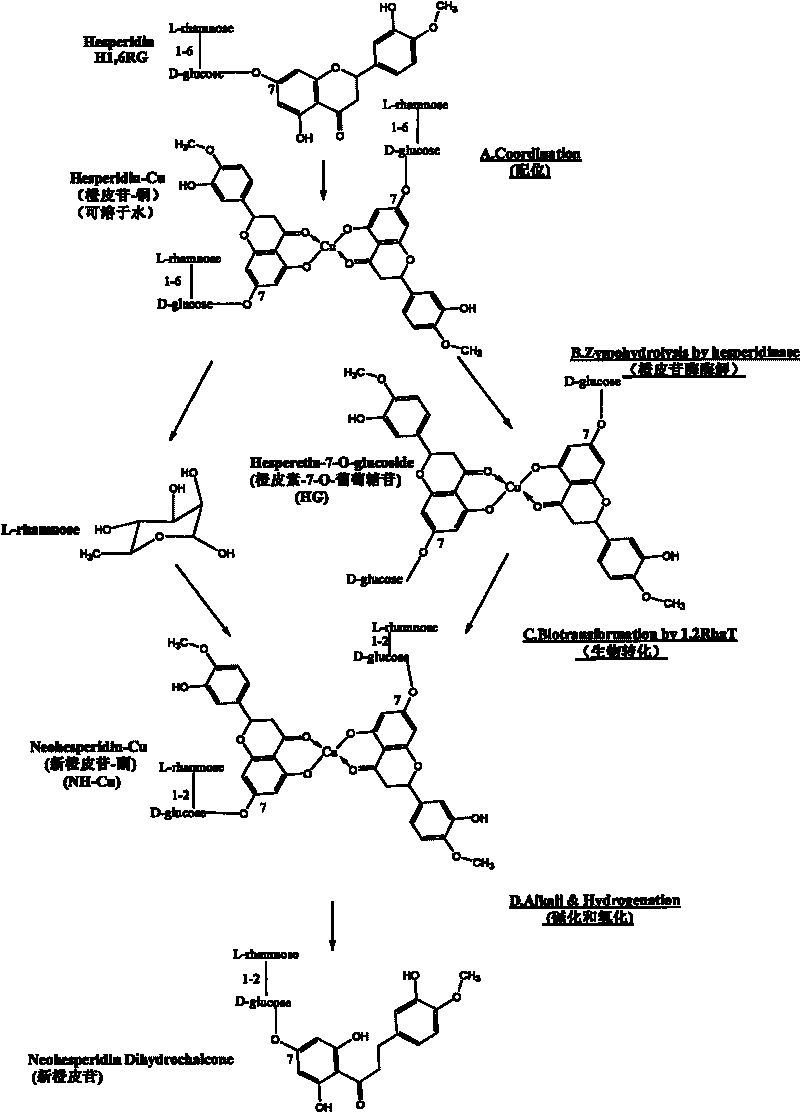

[0029] Such as figure 1 As shown, the new method for high-throughput enzymatic conversion of hesperidin to neohesperidin is mainly realized through the following four steps: pairing of hesperidin and metal ions (I), formation of hesperidin metal complexes Enzymatic hydrolysis of hesperidin (II), biotransformation of the hydrolyzed product of hesperidin, i.e. high-throughput enzymatic synthesis of neohesperidin metal complexes (III) and decoordination of neohesperidin metal complexes (IV).

[0030] Configure 6×10 with 80% methanol -3 mol / L hesperidin and 3×10 3 mol / L CuCl 2 Solution, airtight reaction in 40 ℃ of water baths 1h, rotary evaporation reclaims methanol and HCl, obtains hesperidin copper complex aqueous solution, concentration 1.85g / L, higher than the solubility of hesperidin more than 100 times (I). Hesperidinase was immobilized by glutaraldehyde cross-linking method, and acted on the above-mentioned hesperidin metal complex aqueous solution, the reaction temper...

Embodiment 2

[0032] Example 2 is similar to Example 1. The difference is: the concentration of methanol in step I is adjusted to 50%, by Cu(NO 3 ) 2 Provide Cu 2+ Coordinate with hesperidin, adjust the reaction temperature to 85°C; adjust the action temperature of hesperidinase in step II to 65°C, adjust the reaction pH to 2.0, and the reaction time is only 20min at this time, indicating that the enzyme activity under this condition Higher than Example 1; rhamnosyltransferase 1 in step (III), the action temperature of 2-RhaT is adjusted to 25 ℃, and this immobilized enzyme can be reused for 24 hours equally; Adjusting the pH to 11.5 can also precipitate Cu in the copper ammonium complex 2+ ’, realizing the high-throughput enzymatic conversion of hesperidin to neohesperidin.

Embodiment 3

[0034] Configure 6×10 with 70% methanol -3 mol / L hesperidin and 3×10 3 mol / L FeCl 2 The solution was airtightly reflected in a water bath at 65° C. for 1 h, and methanol and HCl were recovered by rotary evaporation to obtain an aqueous solution of hesperidin-ferrous complex with a concentration of 2.01 g / L, which was more than 110 times higher than the solubility of hesperidin (I). The hesperidinase was immobilized by glutaraldehyde cross-linking method, and acted on the above-mentioned hesperidin ferrous complex aqueous solution, the reaction temperature was 55°C, the reaction pH was 3.0, and the reaction time was 40min. In the ultraviolet-visible spectrum scanning, the characteristic absorption peak of the hesperidin ferrous complex at around 380nm no longer appears. The enzymatic hydrolysis product does not need to be separated, and is directly used as a substrate for rhamnosyltransferase (II). Rhamnosyltransferase 1,2-RhaT from tobacco or carrot plant cells was also imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com