Method of coating MOF to improve photostability of gold nanocluster and application thereof

A technology of gold nanoclusters and photostability, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that ligands and surfactants are difficult to remove, gold nanoclusters light Problems such as poor stability and limited scope of application of traditional methods have achieved good application prospects, easy large-scale promotion and application, and improved photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

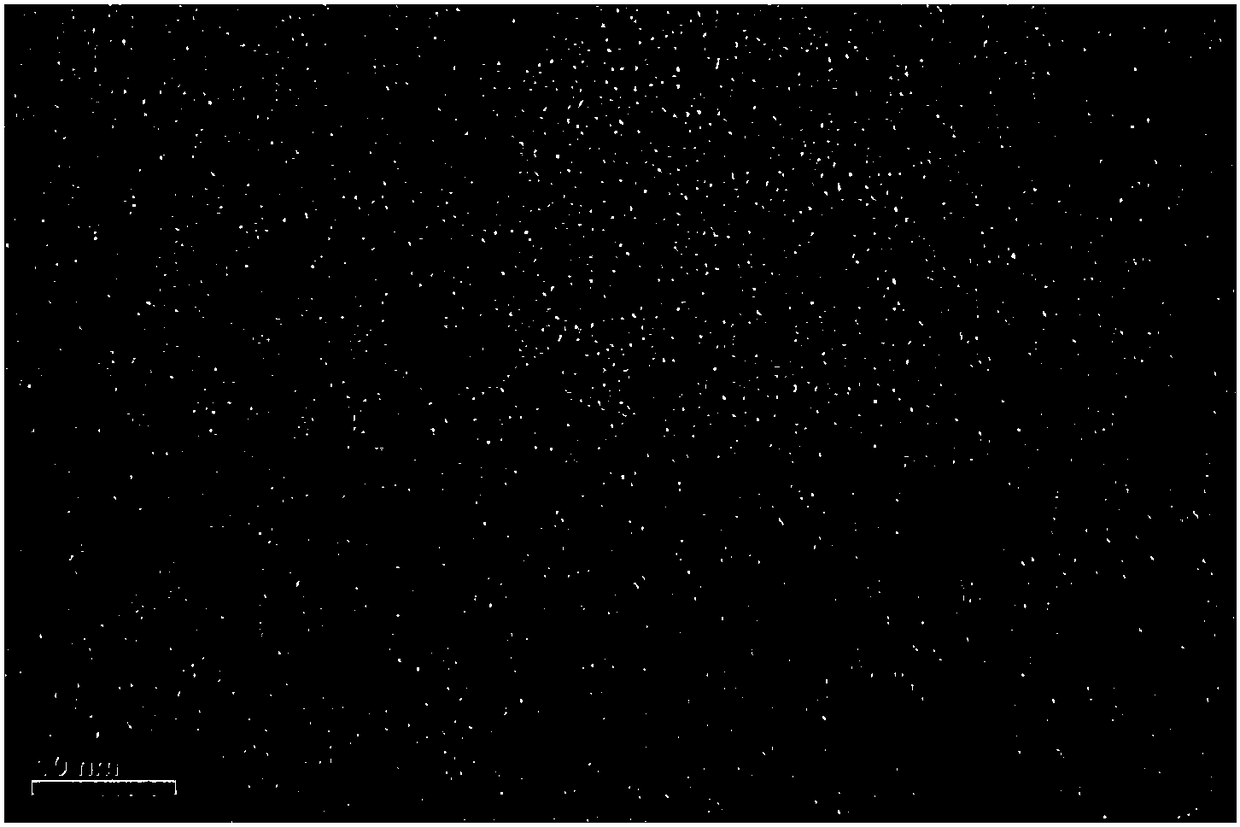

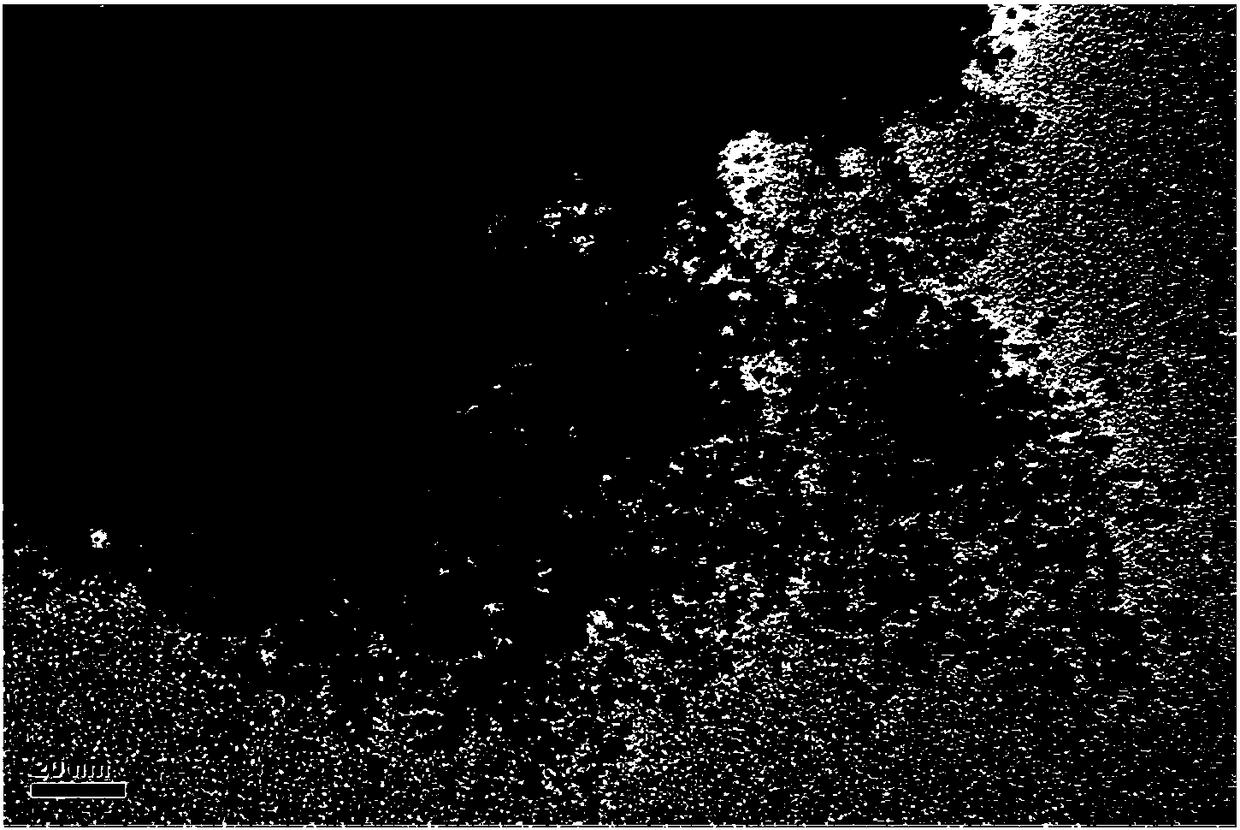

Embodiment 1

[0035] A metal-organic framework-coated gold nanocluster (Au x @ZIF-8) composite material, which was prepared by the following steps: 48.5mg HAuCl 4 4H 2 O was dissolved in 30mL of water, then 50mg of reduced glutathione was added, stirred for 2h until the solution was colorless, and then reacted at 70°C for 24h to obtain a yellow gold nanocluster solution; to the yellow gold nanocluster solution 90mL of acetonitrile was added as a precipitating agent, and the precipitate was separated after centrifugation at 8000rpm for 5min, and the precipitate was washed 3 times with the solution of acetonitrile / water=3 / 1 (volume ratio), and dried to obtain pure solid gold nanoclusters; Solid gold nanoclusters (Au x ) was dispersed into 25 mL of water by ultrasonication at 90 Hz for 30 minutes to form a gold nanocluster dispersion; the formed gold nanocluster dispersion was cooled to 0° C. with an ice-water bath, 410 mg of 2-methylimidazole was added thereto, and stirred until dissolved. ...

Embodiment 2

[0039] A metal-organic framework-coated gold nanocluster Au x @ZIF-67 composite material, which was prepared by the following steps: 48.5mg HAuCl 4 4H 2 O was dissolved in 30mL of water, then 50mg of reduced glutathione was added, stirred for 2h until the solution was colorless, and then reacted at 70°C for 24h to obtain a yellow gold nanocluster solution; to the yellow gold nanocluster solution 90mL of acetonitrile was added as a precipitating agent, and the precipitate was separated after centrifugation at 8000rpm for 5min, and the precipitate was washed 3 times with the solution of acetonitrile / water=3 / 1 (volume ratio), and dried to obtain pure solid gold nanoclusters; Solid gold nanoclusters (Au x ) was dispersed into 25 mL of water by ultrasonication at 90 Hz for 30 minutes to form a gold nanocluster dispersion; the formed gold nanocluster dispersion was cooled to 0° C. with an ice-water bath, 600 mg of 2-methylimidazole was added thereto, and stirred until dissolved. ...

Embodiment 3

[0043] A metal-organic framework-coated gold nanocluster (Au x @ZIF-8) composite material, which was prepared by the following steps: 164.7mg HAuCl 4 4H 2 O was dissolved in 5 mL of water, 255.8 mg of tetraoctyl ammonium bromide was dissolved in 10 mL of toluene, the two solutions were mixed, vigorously stirred for 15 min, the water phase was separated by standing, the oil phase was collected, and the N 2 30min, and cooled to 0°C, adding phenethanethiol in an equimolar amount to gold, stirring at a low speed for 1h to obtain a colorless solution; then quickly adding 155mg NaBH to the colorless solution under rapid stirring 4 , N 2 Stir overnight under protection, wash three times with absolute ethanol, and dry to obtain pure solid gold nanoclusters; then solid gold nanoclusters (Au x ) was dispersed into 25mL water with 90Hz ultrasound for 30min to form a gold nanocluster dispersion; the formed gold nanocluster dispersion was cooled to 0°C with an ice-water bath, 1.64g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com