Preparation method and application method of iron-zirconium composite oxide catalyst

A technology of composite oxides and application methods, which is applied in the field of preparation of iron-zirconium composite oxide catalysts with adjustable dual functions and iron-zirconium composite oxide catalysts, which can solve the problems of difficult recycling, high cost of methyl iodide, and reduced catalyst activity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Accurately weigh Fe(NO 3 ) 3 .9H 2 O, 60.66g (0.15mol), Zr(NO 3 ) 2 .5H 2 O, 12.88g (0.03mol) was dissolved in deionized water, then weighed 45.39g of citric acid, dissolved in deionized water. Pour the aqueous solution of iron-zirconium into the aqueous solution of citric acid, stir, add 12ml of ethylene glycol, stir in a water bath at 60°C for 2 hours at a constant temperature, add ammonia water dropwise to adjust the pH value to 7, and stir at reflux at a constant temperature of 80°C for 2 hours until Sol. The sol was taken out, aged at room temperature for 12 hours, then placed in a vacuum drying oven, and dried at a constant temperature of 80° C. for 12 hours to obtain a catalyst precursor. Put the catalyst precursor into a muffle furnace for roasting, and roast at a constant temperature of 500° C. for 5 hours to prepare the desired iron-zirconium composite oxide catalyst.

[0016] Put 1 g of iron-zirconium composite oxide catalyst, 3 g of 4A molecular sieve...

Embodiment 2

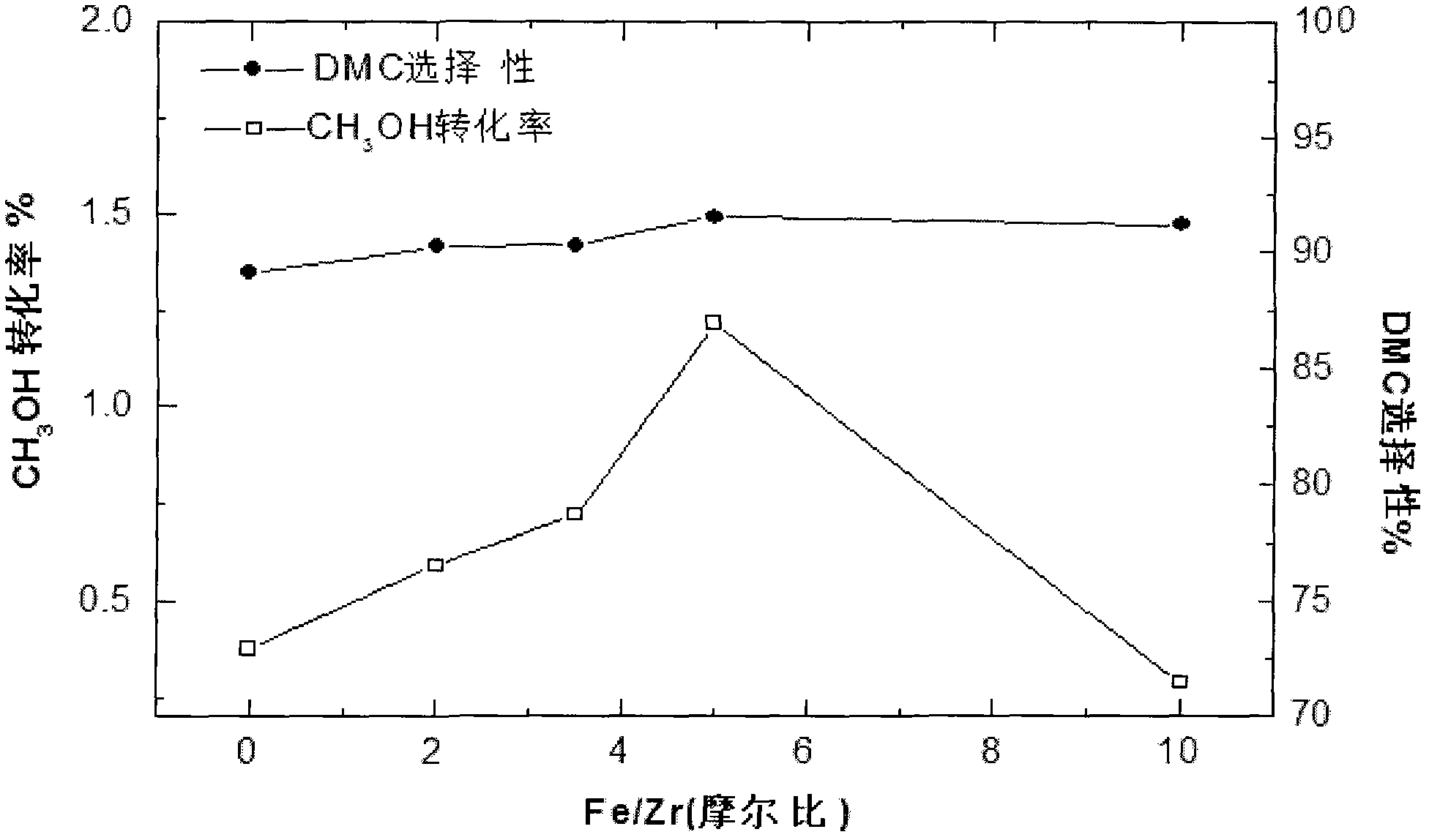

[0024] According to the preparation method of the iron-zirconium composite oxide in Example 1, Fe: Zr molar ratios were respectively prepared as 10: 1, 5: 1, 2: 1 and 1: 1 catalysts, using a high-pressure reactor, according to the activity evaluation method of the catalyst , at CO 2 The reaction was carried out under the conditions of a pressure of 5 MPa (normal temperature), a reaction temperature of 150° C., and a reaction time of 24 hours. The obtained reaction liquids were quantitatively analyzed using the above-mentioned gas chromatography conditions. Experimental results such as figure 1 The results show that the catalytic activity of the Fe-Zr composite oxide catalyst increases first and then decreases with the addition of Fe. When the molar ratio of Fe:Zr is 5:1, the methanol conversion reaches the highest value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com