Biotic plate propoller ship for

A thruster, flat plate technology, applied in the direction of non-rotating propulsion elements, etc., can solve the problems of no Weis-Fogh effect and no good continuity of motion, and achieve the effects of small wake, simple manufacturing and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

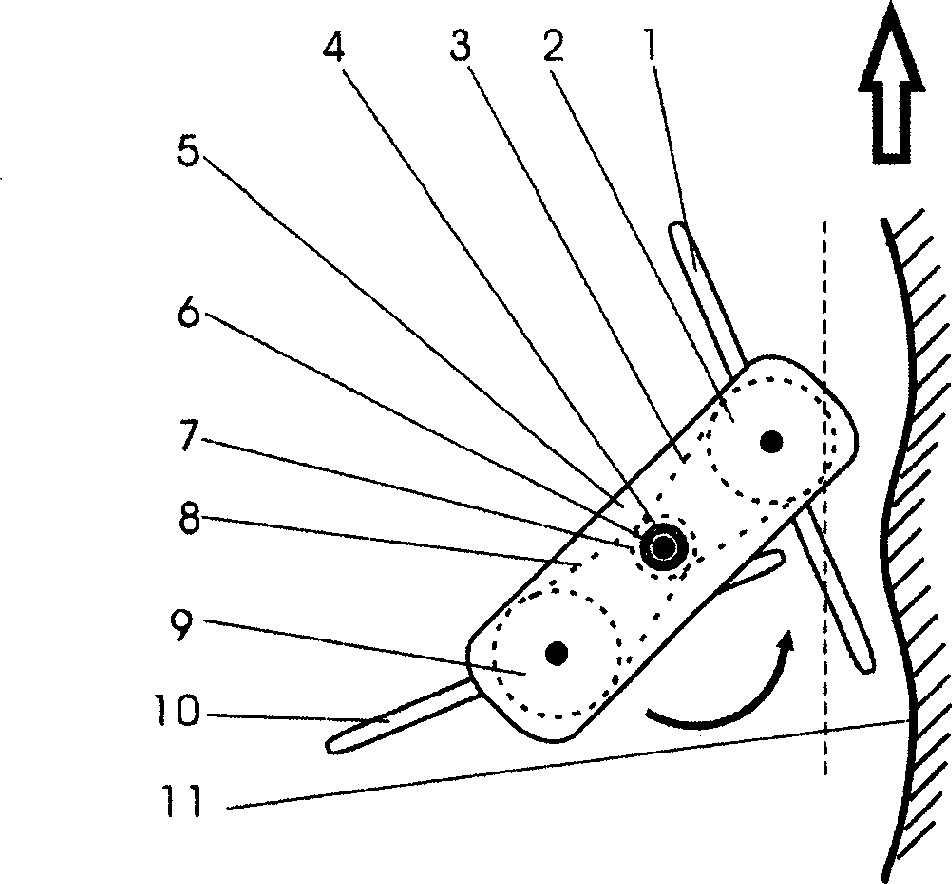

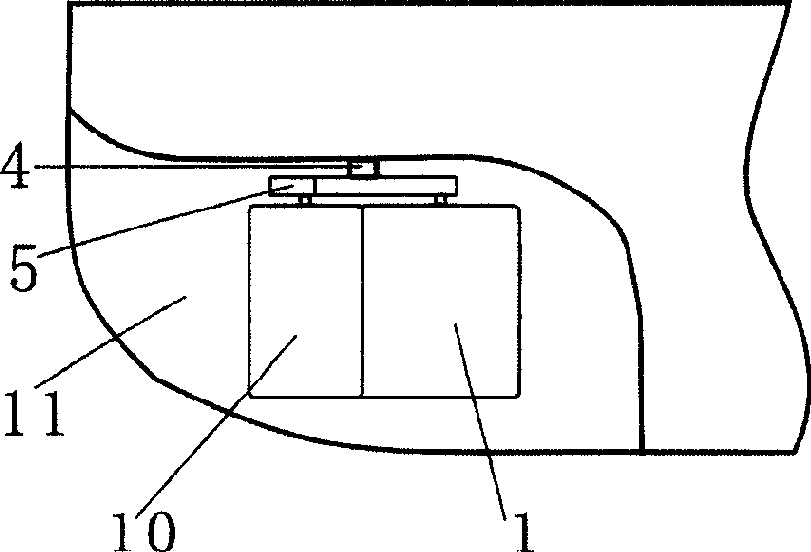

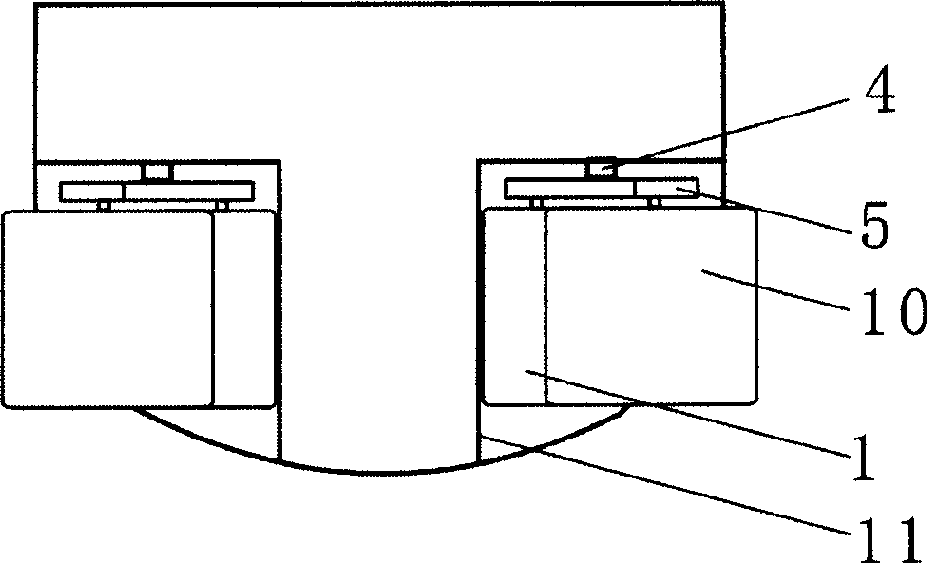

[0014] Such as figure 1 As shown, the bionic flat plate ship propeller of the present invention mainly consists of: the rotating arm shaft 4, the rotating arm 5, the flat blades 1 and 10, the fixed wheel shaft 6 inside the fixed wall 11 and the rotating arm 5, the fixed wheel 7, the transmission chain 3 and 8, moving wheel 2 and 9 form. The fixed wall 11 is a part of the hull, at the bottom of the stern, the direction is parallel to the longitudinal symmetrical plane of the hull, the fixed wall 11 here is made into a curved surface according to the motion track of the edge of the flat paddle 1 or 10, and a simple plane shape can also be adopted, such as image 3 shown. The pivoting arm shaft 4 is perpendicular to the plane of the ship deck and is installed near the fixed wall 11. The distance between the pivoting arm shaft 4 and the fixed wall 11 should make the edges of the flat blades 1 and 10 very close to the fixed wall 11 but not touch the fixed wall 11 when rotating. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com