Airplane deicing vehicle with vehicle chassis adopting wire control technology

A technology for de-icing vehicles and chassis, used in aircraft parts, vehicle components, vehicles used for freight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

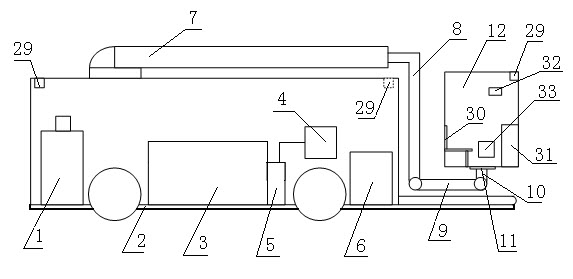

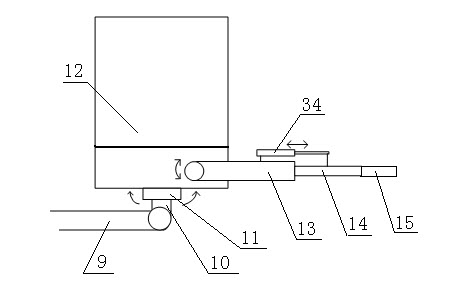

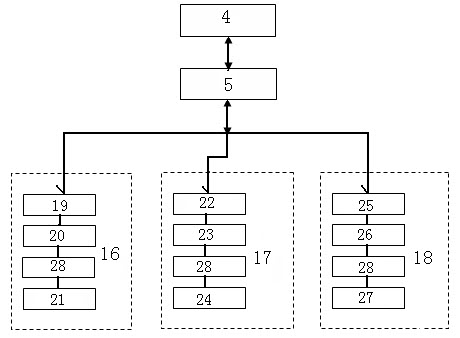

[0013] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as Figure 1 ~ Figure 3 As shown: the deicing fluid heater 1 is installed and fixed on the rear part of the chassis 2 of the vehicle controlled by wire; the deicing fluid pump 3 is installed and fixed on the middle part of the chassis 2 of the vehicle controlled by wire; Front section. A pipeline connection is arranged between the deicing fluid heater 1 and the deicing fluid pump 3; the ECU 4 is connected to the electric control unit board 5 of the vehicle chassis by wire through a data cable. The folding boom 7 is connected with a base welded with the chassis of the vehicle controlled by wire, and the folding boom 7 is connected with the base in a rotating shaft manner. Between the folding arm 7 and the telescopic arm 8 is a hydraulic transmission; between the telescopic arm 8 and the folding arm 9, and betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com