Numerical control rotating cam control fulcrum chute fuzzing mechanism

A technology of raising mechanism and cam control, which is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems of complex transmission structure, unstable beating amount of sley, poor weaving precision, etc., and achieves convenient manufacturing and simple structure , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

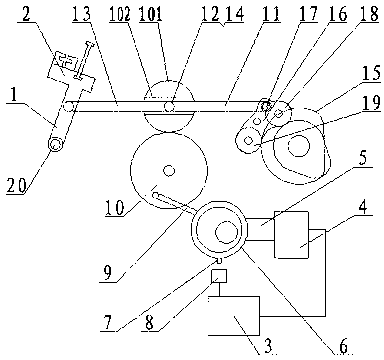

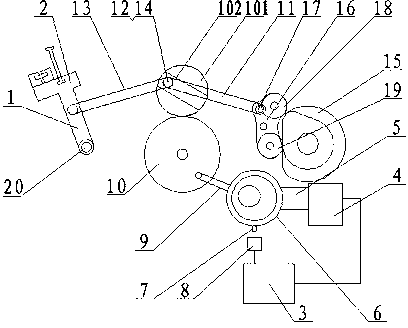

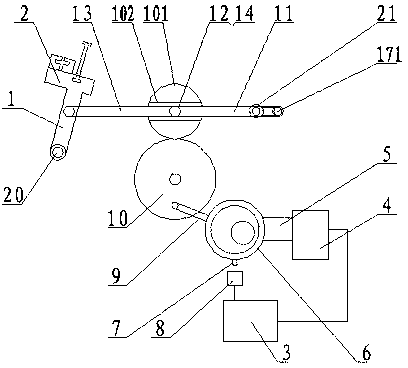

[0020] figure 1 In the first embodiment shown, the fluffing mechanism of the fulcrum chute controlled by the numerically controlled rotating cam includes an electric box 3, a numerically controlled motor 4, a reducer 5, an eccentric rotating cam 6, a signal convex 7, a signal sensor 8, a gear swing rod 9, and a lower gear 10 , Upper gear 101, chute 102, primary transmission link 11, hinge joint 12, secondary transmission link 13, slide block 14, conjugate cam group 15 and swing arm 16. The sley foot 1 swings and rotates with the sley fulcrum 20 as a fulcrum. Sley foot fulcrum 20, conjugate cam group 15, swing arm 16, upper gear 101, lower gear 102, eccentric rotating cam 6 are all installed on the loom frame in the form of bearing rolling connection, and the center distance is relatively fixed . The electric box 3 drives the eccentric rotating cam 6 sequentially thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com