Corrosion-inhibiting mist-suppressing promoter for steel pickling

A steel pickling and accelerant technology, which is applied in the field of iron and steel pickling anti-corrosion and anti-fog accelerators, can solve the problems affecting the continuous production of cold rolling, poor surface quality of hot-rolled plates, and slow pickling speed, etc., to achieve the reduction of iron damage, improve surface quality, and pickling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

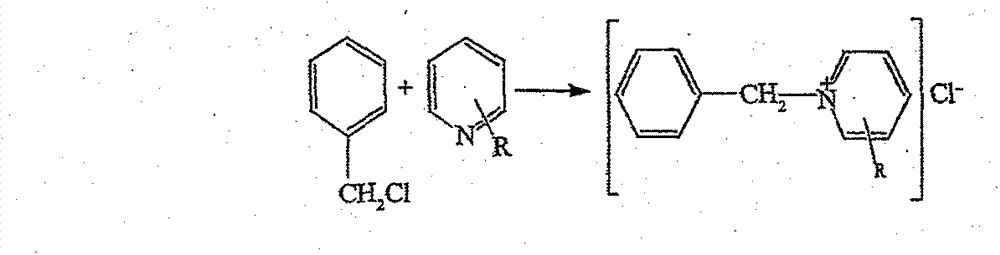

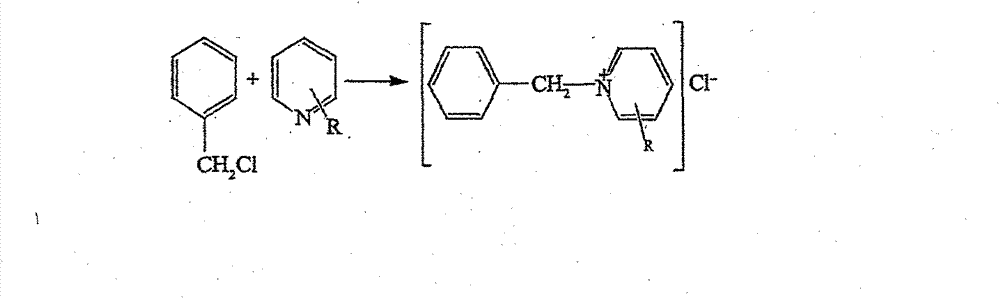

Method used

Image

Examples

specific Embodiment approach

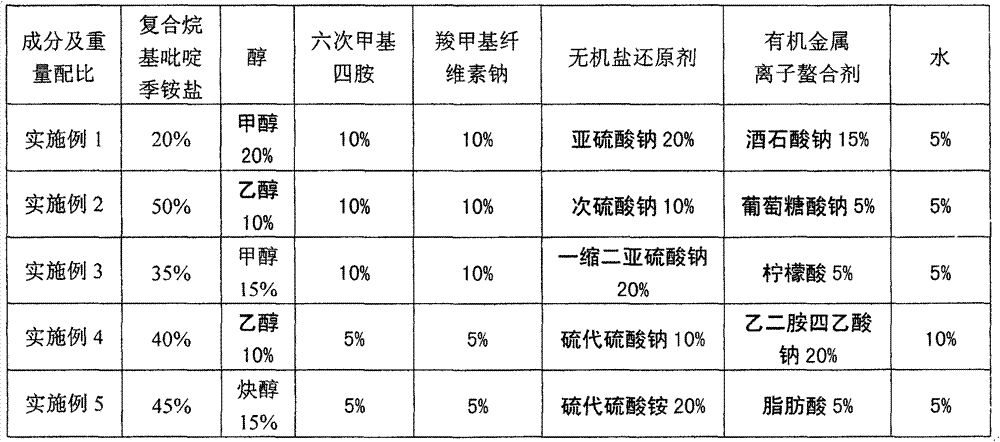

[0029] The specific embodiment of the present invention sees the following table:

[0030]

[0031] When the product of the present invention was put on trial in a steel mill, a scanning electron microscope was made on the surface of the steel plate, and it was found that the pickling product without adding the steel pickling anti-corrosion and anti-fog accelerator of the present invention, especially the surface of difficult-to-clean deep-drawing steel and high-strength steel, was magnified by 50 times, 500 times, and 1000 times, there are a large number of corrosion products and corrosion pits on the surface, and there are a large number of oxide scales, and the pickling product added with the steel pickling anti-corrosion and anti-fog accelerator of the present invention, the surface is magnified by 50 At magnifications of 1, 500, and 1000, there are no corrosion products, no metal oxide scales, and no corrosion pits on the surface. The pictures show that they are all ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com