Hoisting method of hyperbolic water-tower water tank and hoisting device

A hoisting device and hoisting method technology, applied in the direction of hoisting device, tower, building type, etc., can solve the problems of high material consumption, many hidden dangers of high-altitude operation, and inability to construct, so as to achieve low investment and transportation costs, and save equipment rental fees. , the effect of reducing energy consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

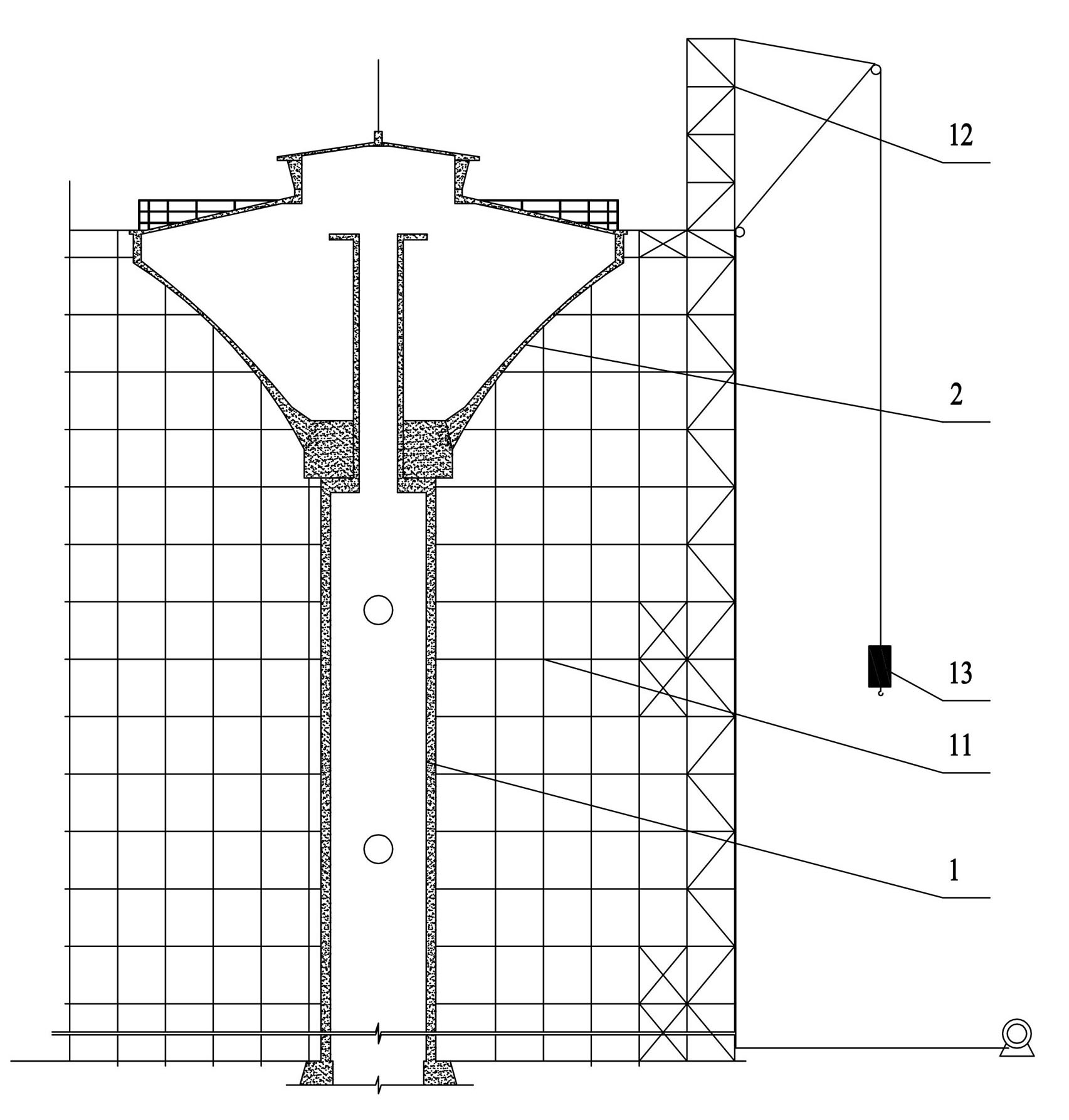

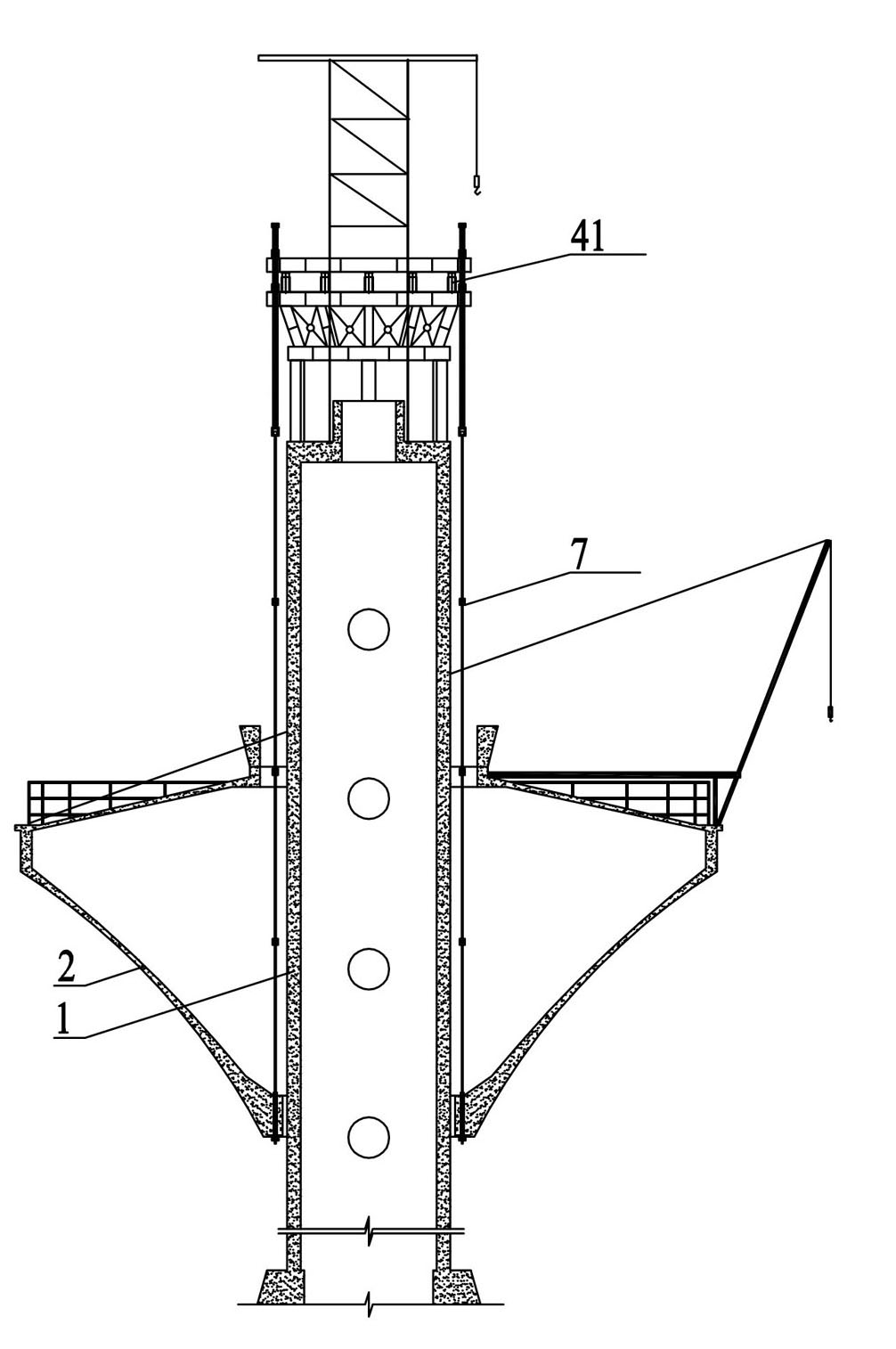

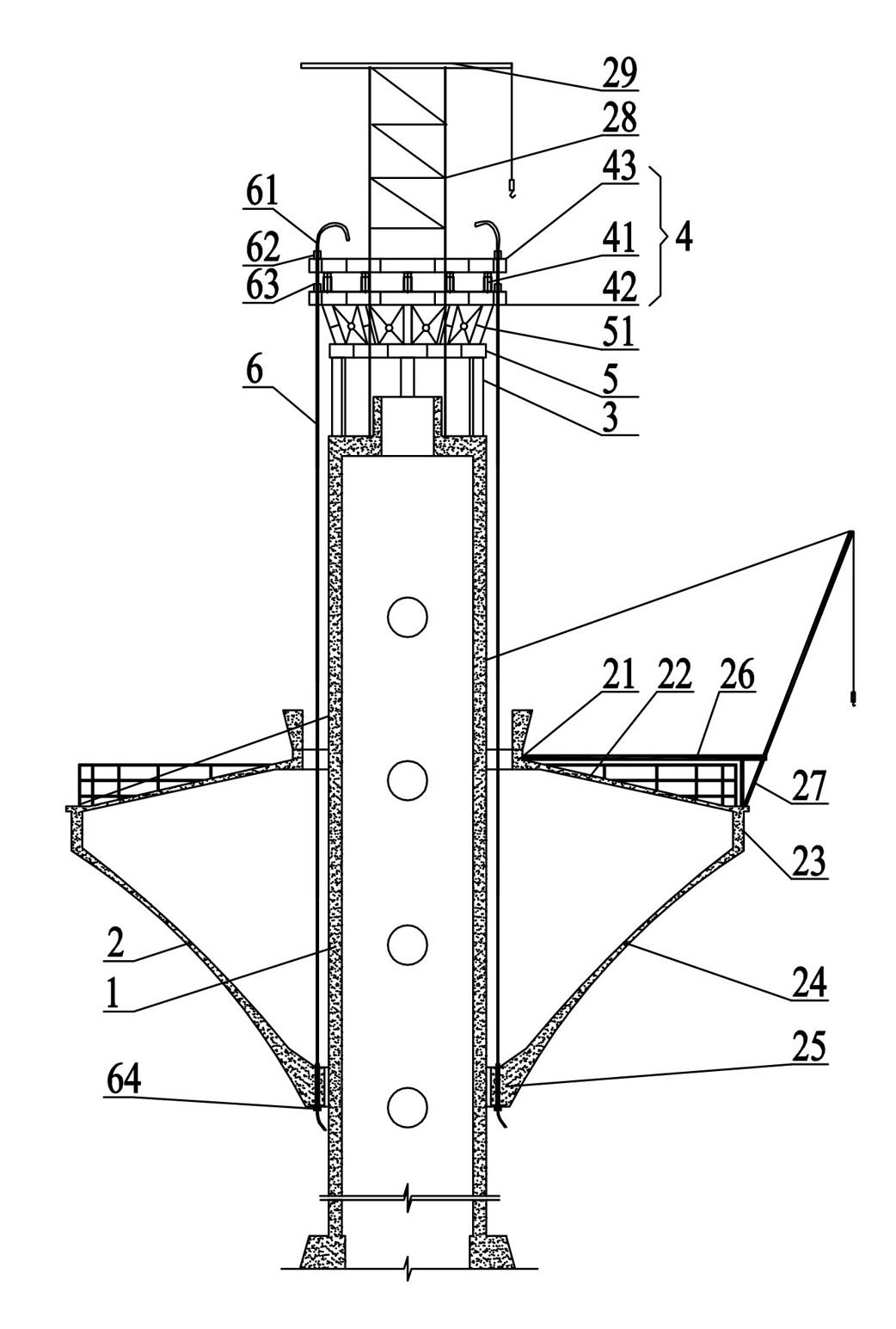

[0040] The water tower design of a steel factory is 1200m 3 / 50m reinforced concrete hyperbolic thermal insulation water tower, the effective volume of the water tower water tank is 1200m 3 , the minimum water level of the water stored in the tower is 50m, and the water tank of the water tower has a hyperbolic shape. In this embodiment, the water tower is constructed using a double-hydraulic combined sliding-lifting construction process (that is, the hydraulic sliding form construction process of the support tube and the hydraulic hoisting construction process of the prefabricated water tank).

[0041] The water tower construction project in this embodiment mainly consists of foundation engineering (the water tower foundation is constructed by the conventional formwork cast-in-place method), support pipe construction (the existing hydraulic sliding form construction method without derrick can be used for construction), water tank construction and project finishing It consists...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com