Arc-shaped titanium alloy thin-walled part forming tooling and method

A thin-walled part and arc-shaped technology, which is applied in the field of metal material forming molds, can solve the problems of high production cost and long processing cycle, and achieve the effects of shortened production cycle, improved production efficiency, and convenient manufacturing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

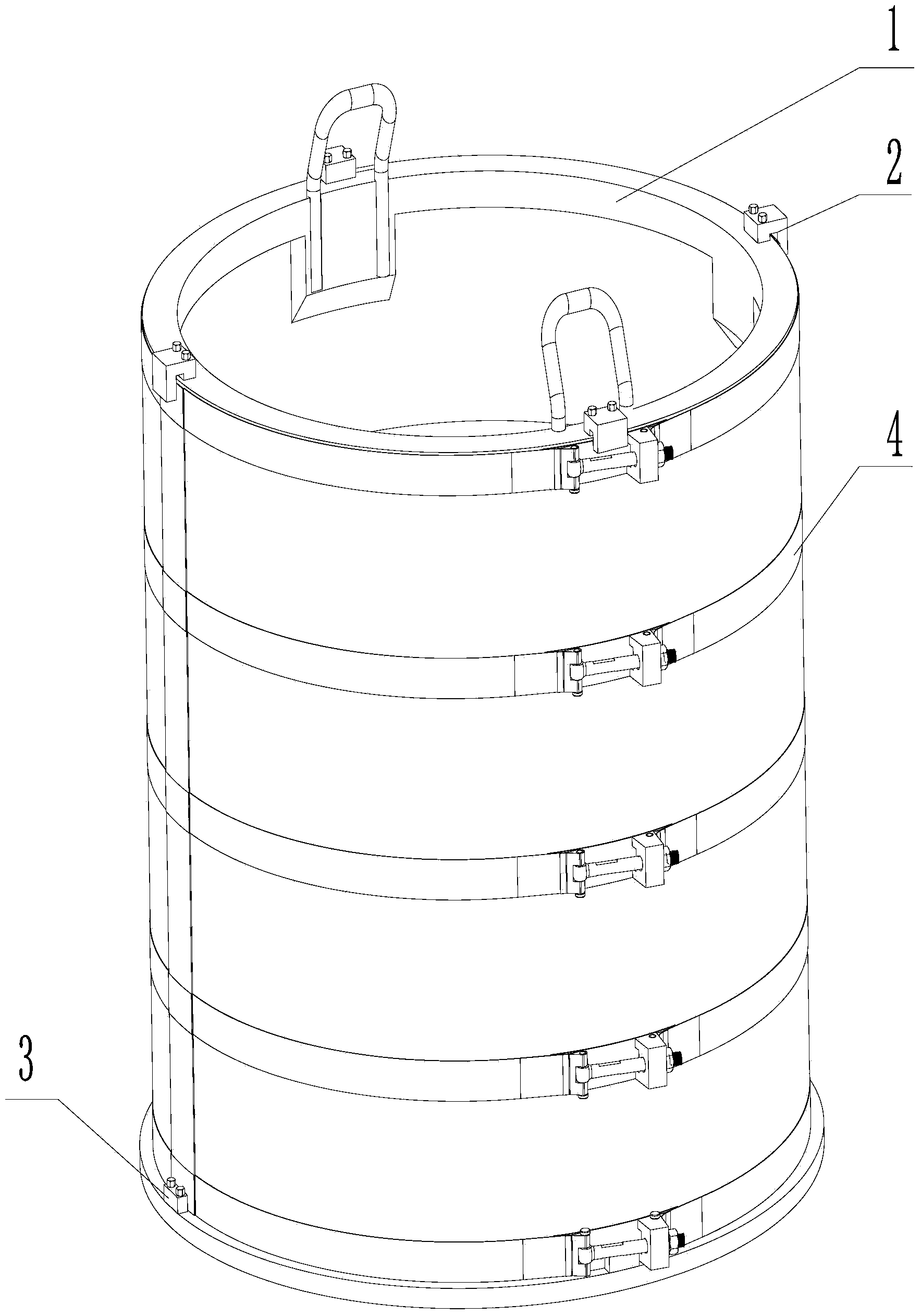

[0043] Such as figure 1 As shown, the embodiment of the titanium alloy arc-shaped thin-walled parts forming tool provided by the present invention includes a cylinder body 1, four limiting blocks 2, four positioning blocks 3 and five wrapping assemblies 4,

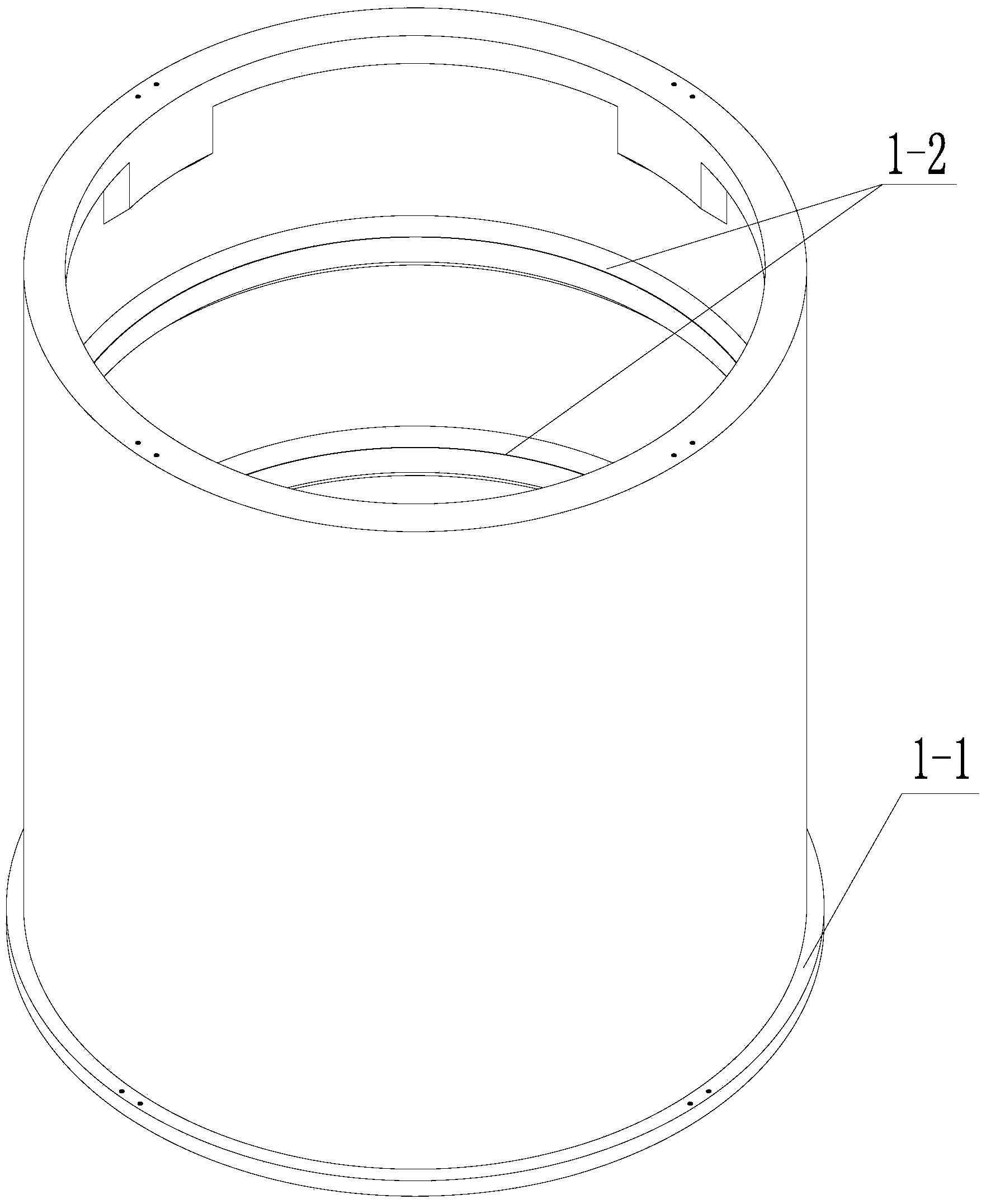

[0044] Such as figure 2 As shown, the cylinder body 1 is cylindrical, and its lower end surface has an annular flange 1-1 for positioning arc-shaped thin-walled parts, and the cylindrical inner wall has a circular rib 1-2 to ensure Rigidity of the cylinder, the outer diameter of the cylinder is equal to the arc inner diameter of the arc-shaped thin-walled part to be formed, which is R955, and the tolerance is +0.3mm~+0.5mm;

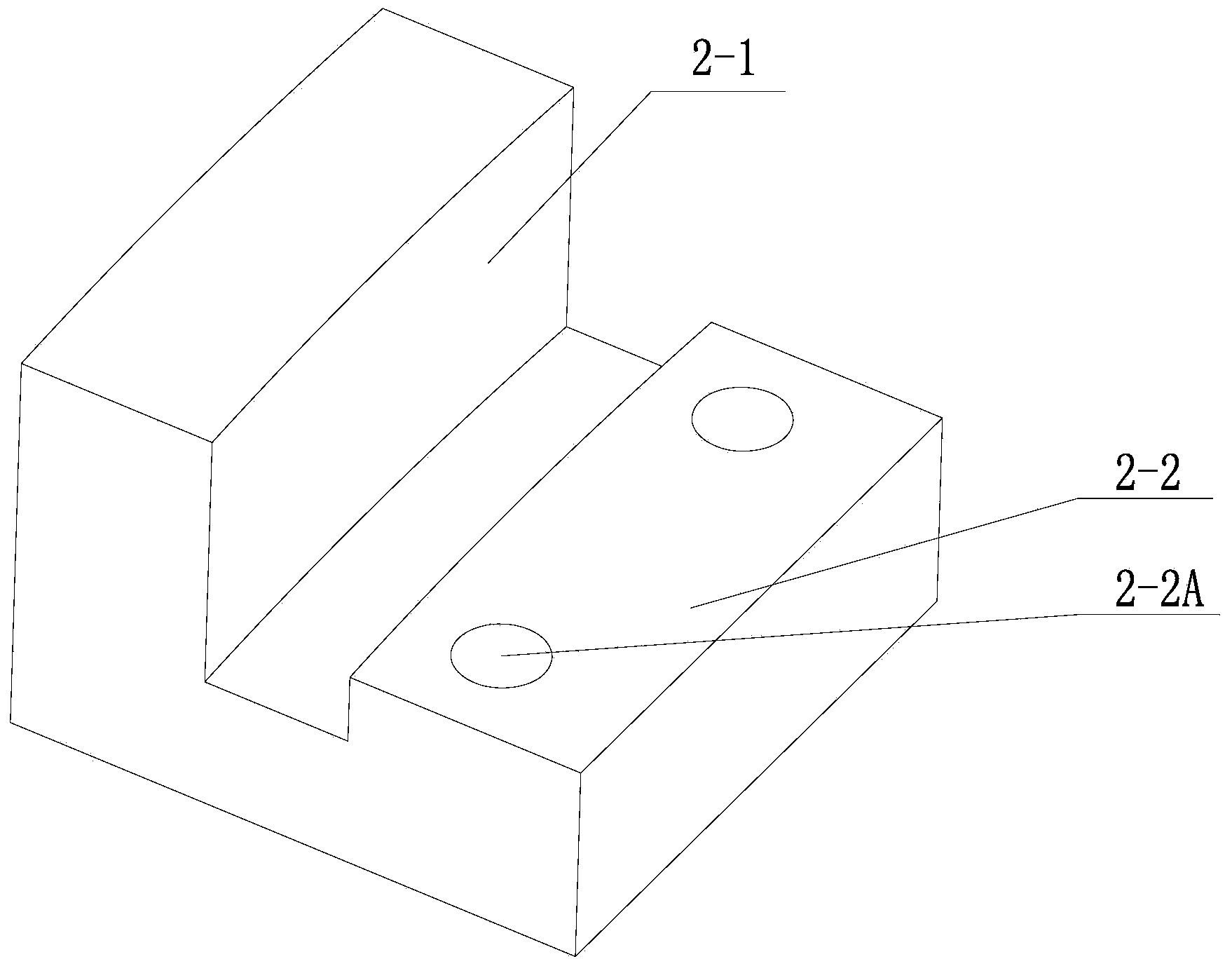

[0045] Such as image 3 As shown, the limiting blocks 2 have the same shape and L-shaped cross-section. They are composed of an integrated vertical plane 2-1 and a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com