Fracturing fluid capable of resisting high salinity water quality

A high-salinity, fracturing fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems that cannot meet the requirements of on-site construction, achieve good economic benefits, improve success rate, and resist gelling. High temperature and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

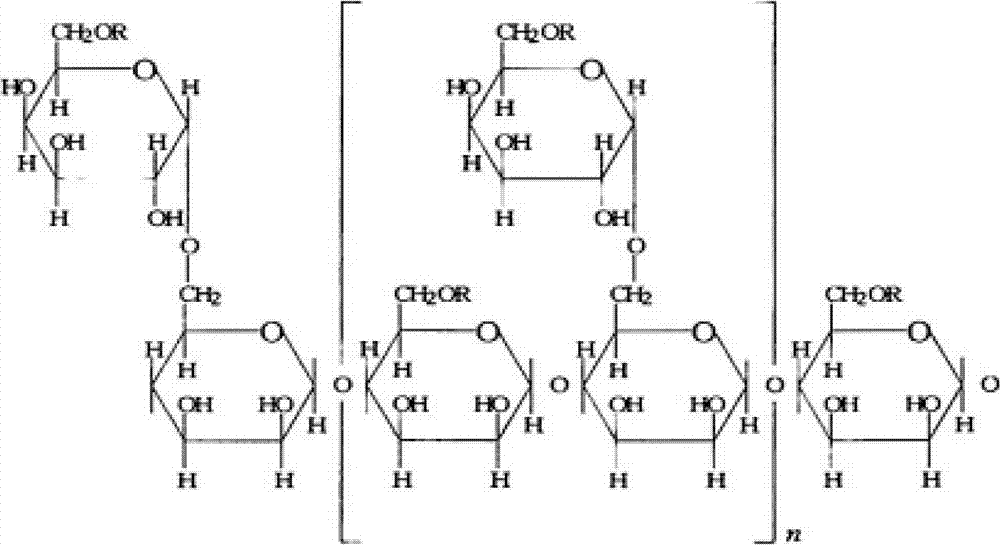

Method used

Image

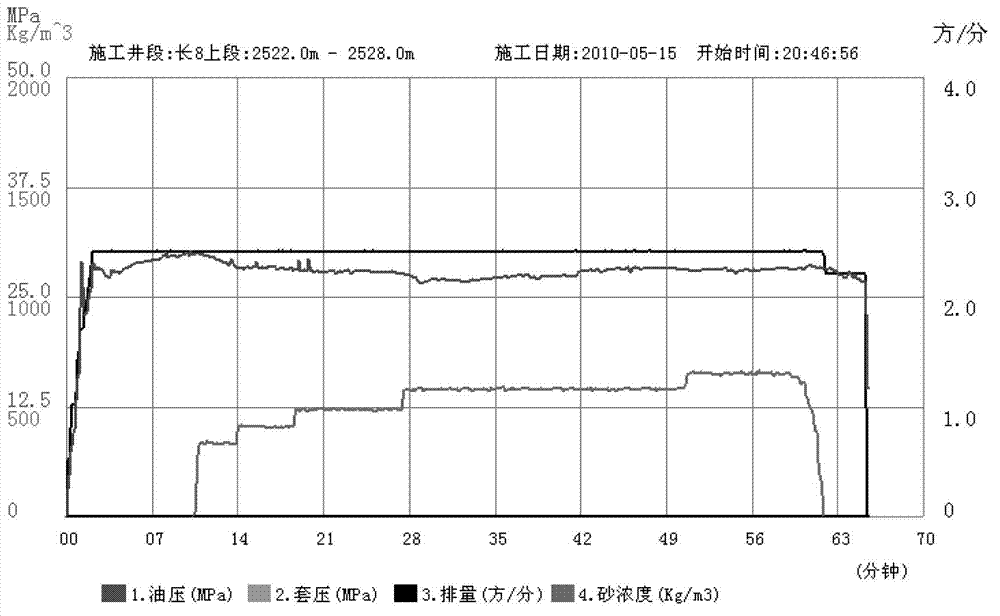

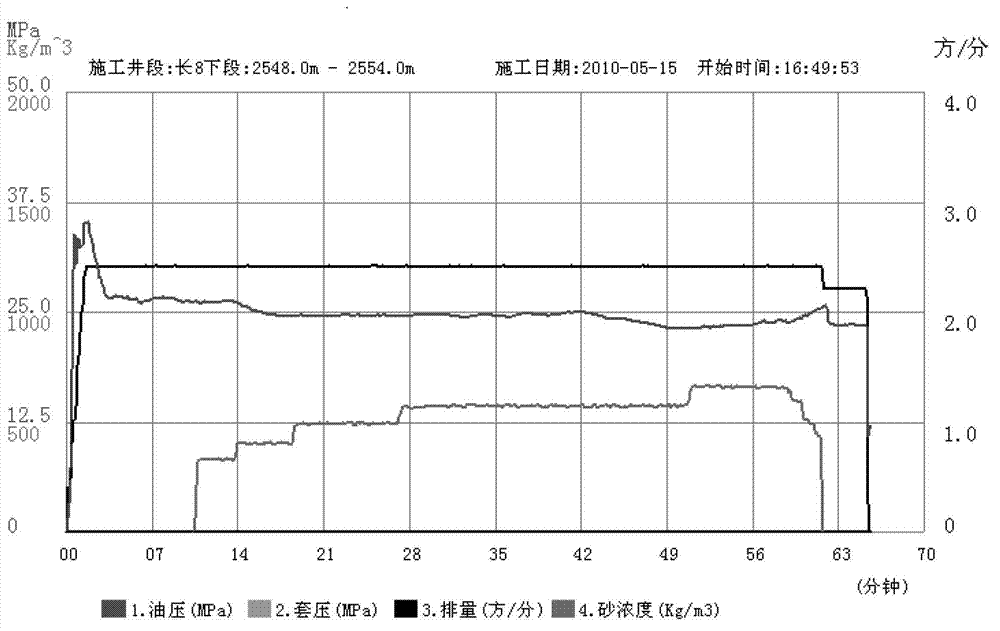

Examples

Embodiment 1

[0052] Example 1 (burial depth ≤ 1700m)

[0053] (1) Preparation of base liquid:

[0054] Proportion of base liquid:

[0055] 98.65kg of high salinity surface water, 0.1kg of chelating co-solvent, 0.3kg of thickener, 0.1kg of fungicide, 0.3kg of clay stabilizer, 0.5kg of demulsification and drainage aid, 0.05kg of chelating stabilizer;

[0056] The preparation process is as follows: in the case of pump circulation or agitator stirring, slowly add the above mass parts of chelating co-solvent, fungicide, thickener, clay stabilizer to the above mass parts of high salinity surface water , Demulsification aid and chelating stabilizer, continue to circulate or stir for 30 minutes, so that the liquid is fully mixed, the thickener is fully swollen, and a uniform liquid is formed;

[0057] (2) Preparation of cross-linking solution:

[0058] Proportion of crosslinking liquid: water 50kg, organic crosslinking agent 50kg, gel breaker 0.35kg;

[0059] The preparation process is as follow...

Embodiment 2

[0063] Example 2 (burial depth ≥ 2700m)

[0064] Basically the same as Example 1, the difference is: the proportioning of the base liquid: high salinity surface water 98.2kg, chelating cosolvent 0.15kg, thickener 0.4kg, bactericide 0.15kg, clay stabilizer 0.5kg , demulsification aid drainage agent 0.5kg, chelating stabilizer 0.1kg;

[0065] Proportion of crosslinking liquid: water 50kg, organic crosslinking agent 50kg, gel breaker 0.35kg;

[0066] The proportion of fracturing fluid: base fluid 99.5kg, cross-linking fluid 0.8kg.

Embodiment 3

[0067] Example 3 (1700m≤burial depth≤2200m)

[0068] Basically the same as Example 1, the difference is: the proportioning of the base liquid: high salinity surface water 98.3kg, chelating cosolvent 0.15kg, thickener 0.35kg, bactericide 0.10kg, clay stabilizer 0.5kg , 0.5 parts of demulsification aid and drainage agent, 0.1 kg of chelating stabilizer;

[0069] Proportion of crosslinking liquid: water 50kg, organic crosslinking agent 50kg, gel breaker 0.35kg;

[0070] Fracturing fluid ratio: base fluid 99.3kg, cross-linking fluid 0.6kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com