Anhydrous fracturing fluid suitable for shale gas and preparation method of anhydrous fracturing fluid

An anhydrous fracturing fluid and shale gas technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high price of triethanolamine oleate, difficult on-site construction, and increased fracturing cost. , to achieve the effect of convenient industrial production, good sand carrying performance, and short gelling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

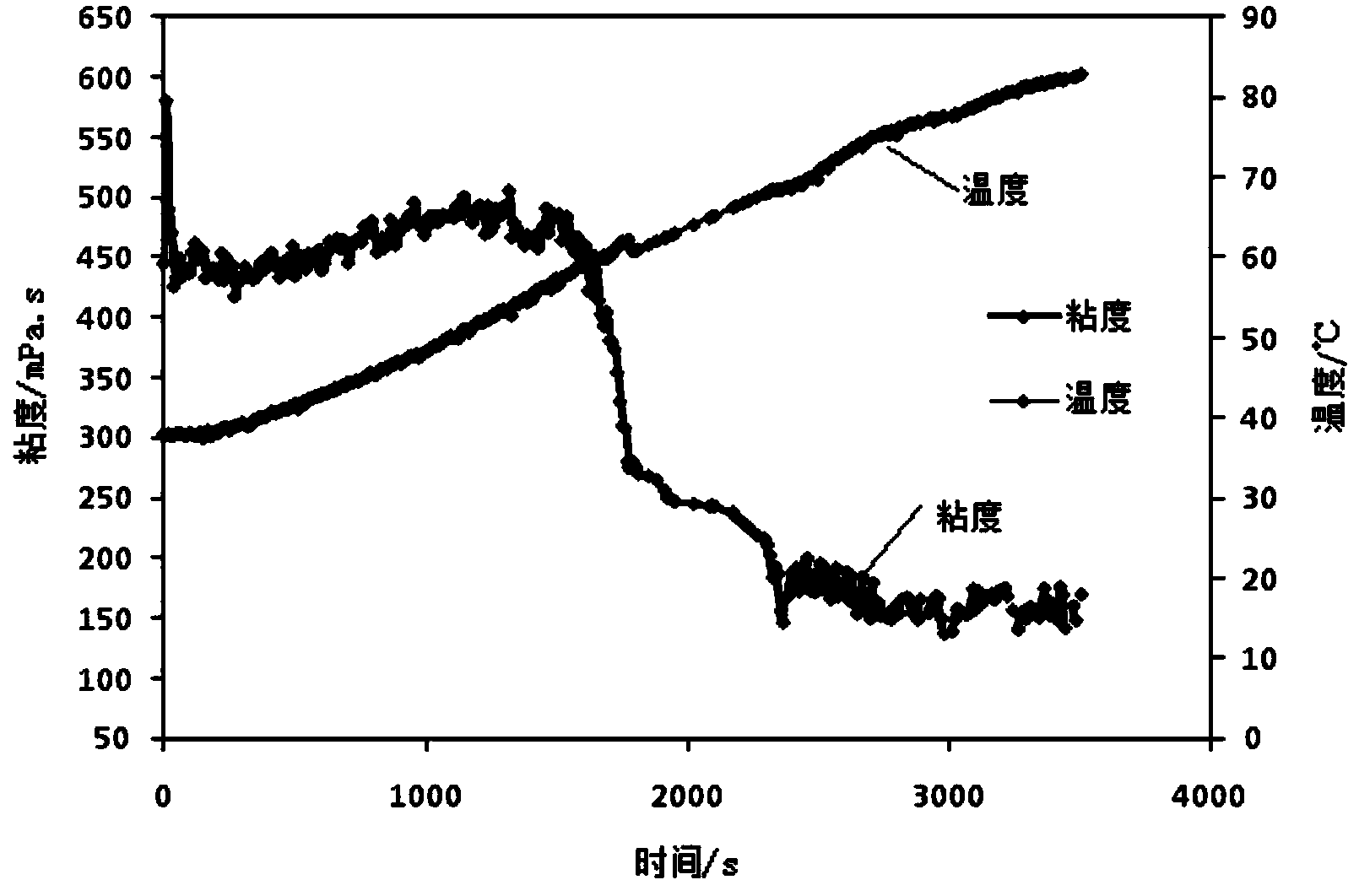

Image

Examples

Embodiment 1

[0015] The anhydrous fracturing fluid suitable for shale gas is made of the following raw materials in mass percentage: 1.5% crosslinking agent, 4.0% complex iron activator, and the rest are low-carbon hydrocarbons.

[0016] Described low carbon hydrocarbon is the mixture of propane and butane;

[0017] Described linking agent is alkyl phosphate, and the content of dialkyl phosphate in alkyl phosphate is 65.8%, and the synthetic method of alkyl phosphate comprises the following steps:

[0018] (1) First by P 2 o 5 React with triethyl phosphate at 80°C for 2 hours, and react with a feed molar ratio of 1:1 to obtain a polyphosphate intermediate.

[0019] (2) Add mixed alcohol to the polyphosphate intermediate described in step (1), mixed alcohol and P 2 o 5 The molar ratio is 3:1, react at 80°C for 4h to obtain alkyl phosphate. The mixed alcohols include ethanol, n-butanol, n-octanol and dodecanol, and the molar ratio between the alcohols is 1:1:1:1. The content of dialkyl...

Embodiment 2

[0023] Anhydrous fracturing fluid suitable for shale gas, made of the following raw materials in mass percentage: 1.8% crosslinking agent, 5% complex iron activator, and the rest are low-carbon hydrocarbons;

[0024] Described low carbon hydrocarbon is the mixture of propane and butane;

[0025] The cross-linking agent is an alkyl phosphate, and the content of dialkyl phosphate in the alkyl phosphate is 68.8%, and the synthetic method of the alkyl phosphate comprises the following steps:

[0026] (1) First by P 2 o 5 React with triethyl phosphate at 80°C for 2 hours, and react with a feed molar ratio of 1.3:1 to obtain a polyphosphate intermediate.

[0027] (2) Add mixed alcohol to the polyphosphate intermediate described in step (1), mixed alcohol and P 2 o 5 The molar ratio is 3:1, react at 90°C for 3h to obtain alkyl phosphate. The content of dialkyl phosphate is 68.8% measured by double indicator titration method.

Embodiment 3

[0032] Anhydrous fracturing fluid suitable for shale gas, made of the following raw materials in mass percentage: 0.5% crosslinking agent, 2% complex iron activator, and kerosene as the rest;

[0033] The cross-linking agent is an alkyl phosphate, and the content of dialkyl phosphate in the alkyl phosphate is 57.4%. The synthetic method of the alkyl phosphate comprises the following steps:

[0034] (1) First by P 2 o 5 React with triethyl phosphate at 80°C for 2 hours, and react with a feed molar ratio of 1.4:1 to obtain a polyphosphate intermediate.

[0035] (2) Add mixed alcohol to the polyphosphate intermediate described in step (1), mixed alcohol and P 2 o 5 The molar ratio is 3:1, react at 100°C for 4h to obtain alkyl phosphate. The content of dialkyl phosphate is 57.4% measured by double indicator titration method.

[0036] Mixed alcohols include n-butanol, n-octanol, tetradecyl alcohol, the molar ratio between alcohols is 1:1:2, mixed alcohols and P 2 o 5 The mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com