Medium carbon steel sheet, quenched member, and method for manufacturing medium carbon steel sheet and quenched member

A manufacturing method and technology for steel plates, which are applied to medium carbon steel plates, quenched components and their manufacturing fields, can solve the problems of small shape accuracy of components, difference in carbide size, and reduced shape accuracy of steel plate hardenability components, and achieve excellent shape accuracy, Excellent cold workability and excellent quenching stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0163] Next, examples will be described.

[0164] The level of the examples is an example of the execution conditions adopted for confirming the possibility and effect of the present invention, and the present invention is not limited by the examples of the conditions. The present invention can adopt various conditions without departing from the gist of the present invention and achieving the object of the present invention.

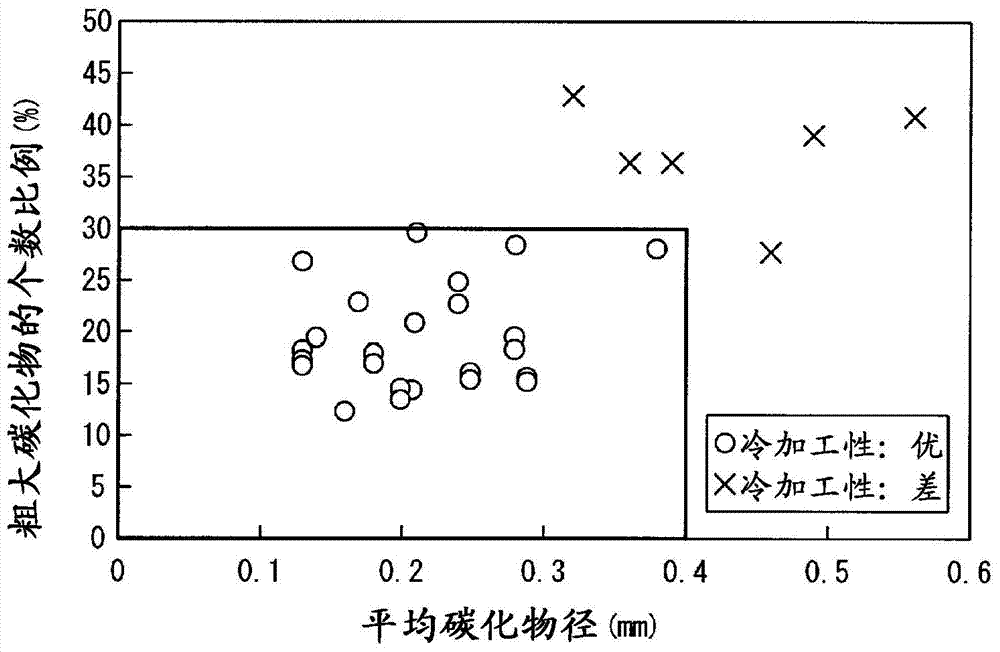

[0165] After hot-rolling the steel ingot (steel) with the chemical composition shown in Tables 1 to 3 (the balance is iron and unavoidable impurities), it is air-cooled for 2.5 seconds, and forced to cool at an average cooling rate of 30°C / s to 540°C, coiled at 500°C, and cooled to room temperature to obtain a hot-rolled sheet. Furthermore, the obtained hot-rolled sheet was cold-rolled at a cold-rolling ratio of 15%, and then annealed at 680° C. for 24 hours to obtain various steel sheets having the microstructure shown in Table 4, and cold workability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com